A real-time monitoring device for near-wall effect of multiphase flow

A real-time monitoring, multi-phase flow technology, used in measuring devices, testing moving fluids/granular solids, instruments, etc., can solve problems such as lack, and achieve the effect of simple and compact structure and simple experimental operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

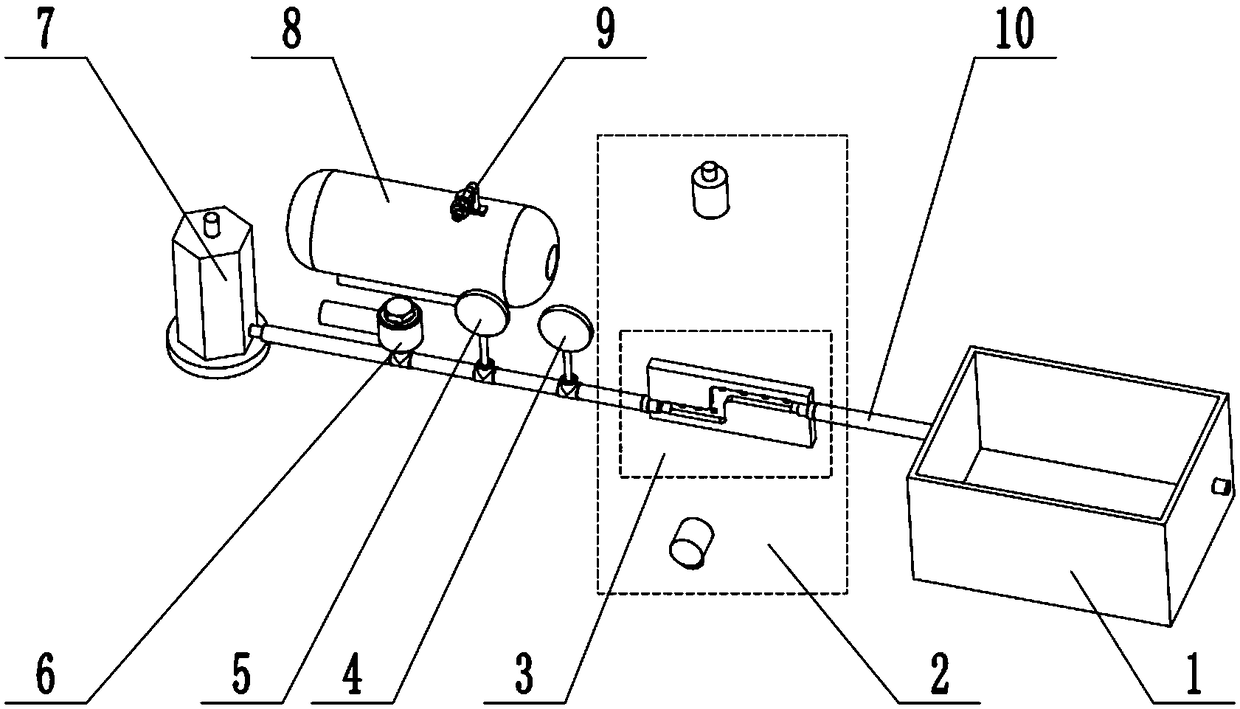

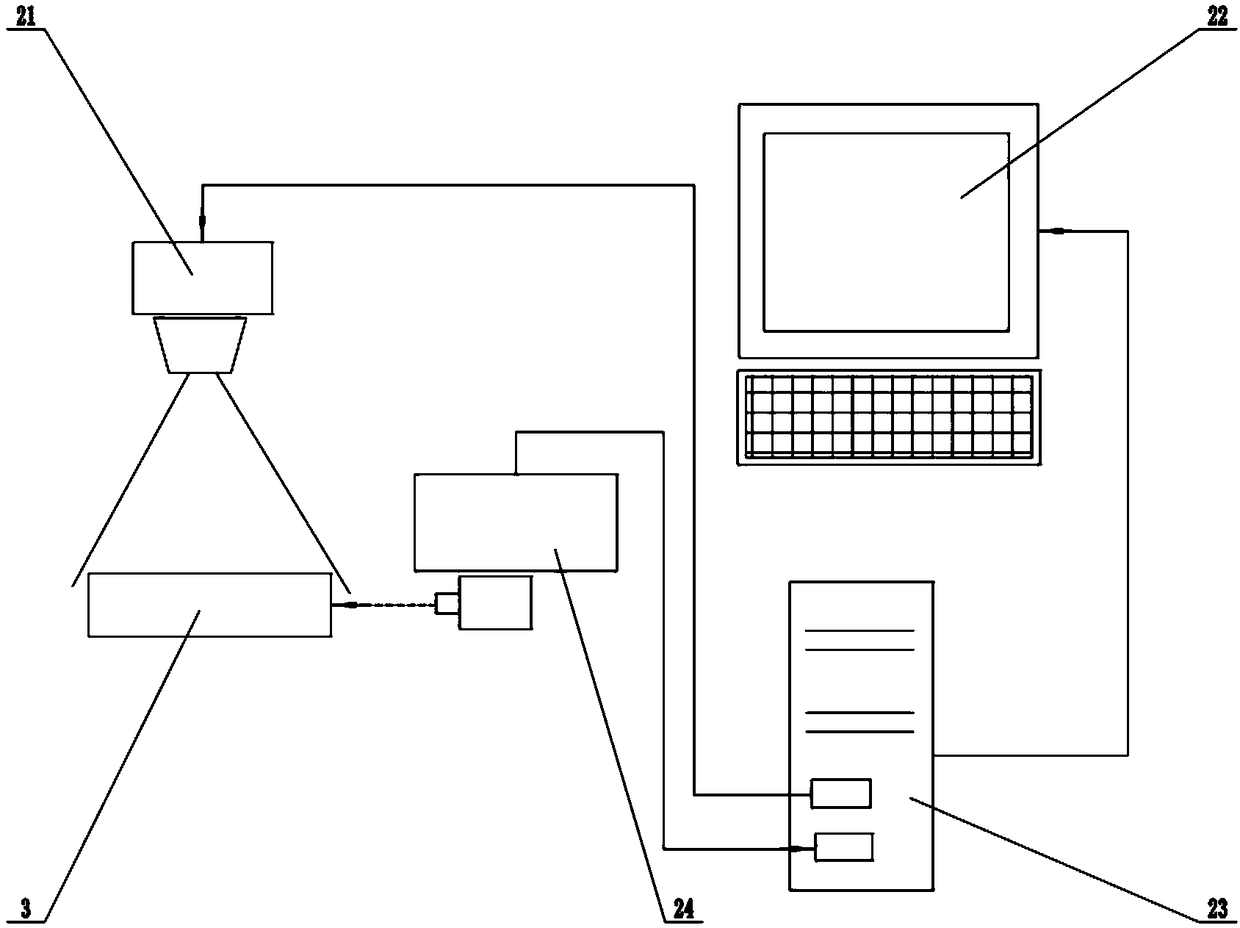

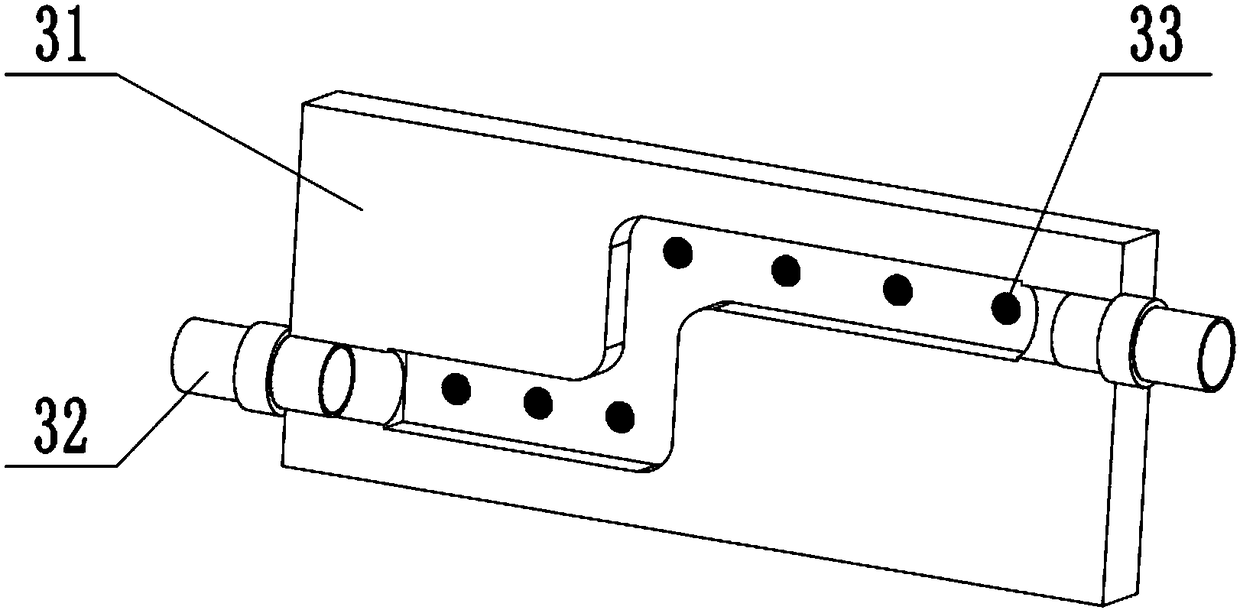

[0019] Such as Figure 1~4 As shown, a real-time monitoring device for near-wall effect of multiphase flow, including image particle observation system 2, pipeline 10, air pump 8, gas nozzle 9; 5. Pressure gauge 4, observation channel device 3 and abrasive flow storage tank 1.

[0020] Abrasive grain agitation pump 7 is in sealing connection with said ball valve 6 through pipeline 10, and the outlet flow of said abrasive grain agitation pump 7 is controlled by adjusting said ball valve 6; The pipeline 10 between the stirring pump 7 and the observation channel device 3 is sealed and connected, the air nozzle 9 is connected to the outlet of the air pump 8 and connected to the observation channel device through a gas pipe, and the abrasive particle flow storage tank 1 The outlet of the abrasive grain agitation pump 7 is sealedly connected to the inlet of the abrasive grain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com