Flexible hinge beam fiber Bragg grating two-dimensional acceleration sensor

An acceleration sensor, fiber Bragg technology, applied in multi-dimensional acceleration measurement, acceleration measurement using inertial force, etc., to achieve the effect of convenient downhole, large dynamic range and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

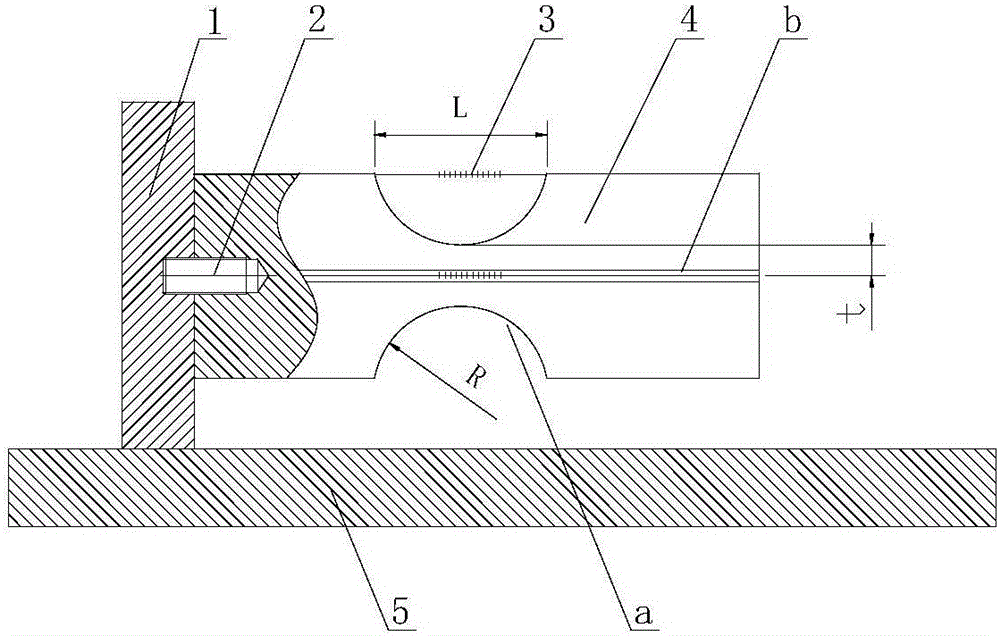

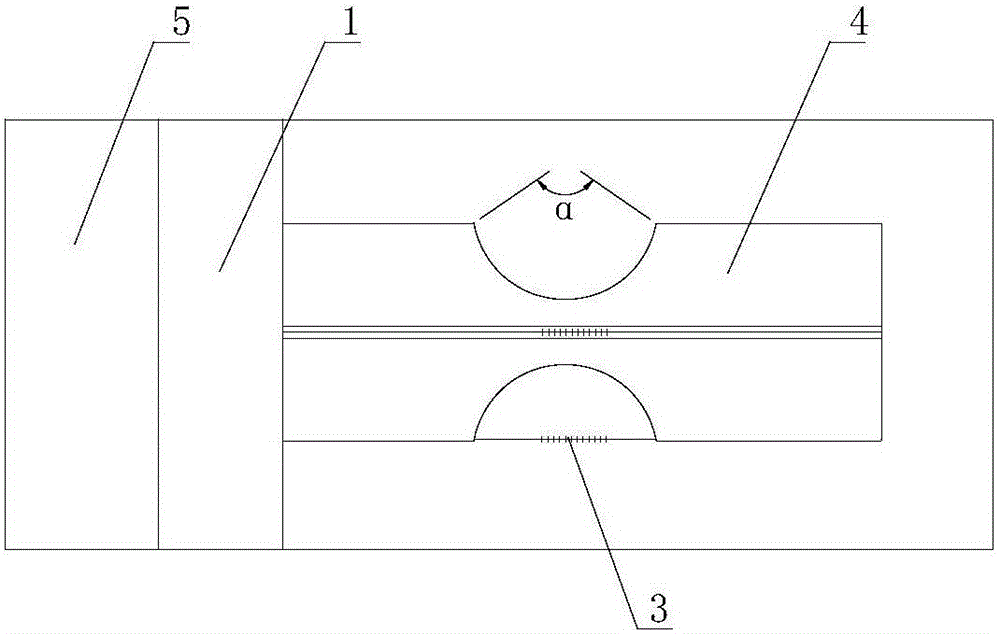

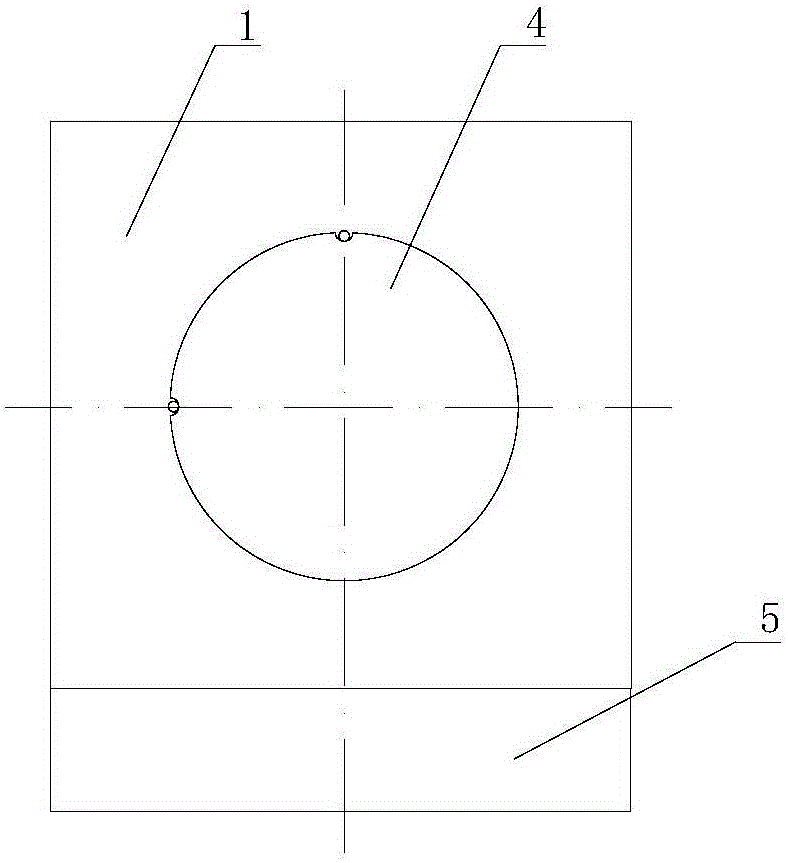

[0019] exist figure 1 , 2 , 3, the flexible hinge beam fiber Bragg grating two-dimensional acceleration sensor of this embodiment is composed of a support 1 , a screw 2 , a fiber Bragg grating 3 , a flexible hinge beam 4 , and a base 5 . One side of the base 5 is fixedly connected with a support 1 with a threaded fastening connector, and a cylindrical flexible hinge beam 4 is connected with a screw 2 on the support 1. The material of the flexible hinge beam 4 is 304 stainless steel, and the circumference of the flexible hinge beam 4 is The cross-sectional geometric shape of the measuring groove a in the direction is an arc, the central angle α opposite the arc is 90°, and the radius of the arc is:

[0020] R = L 2 s i n α 2

[0021] In the formula, L is the length of the grid area of the fiber Brag...

Embodiment 2

[0030] In this embodiment, the cross-sectional geometric shape of the measuring groove a in the circumferential direction of the flexible hinge beam 4 is an arc, the central angle α to which the arc is opposite is 30°, and the radius of the arc is:

[0031] R = L 2 s i n α 2

[0032] In the formula, L is the length of the grid area of the fiber Bragg grating 3, and α is the central angle of the arc. The difference t between the radius of the flexible hinged beam 4 and the depth of the measuring groove a is 0.25mm. Two optical fiber installation grooves b are processed axially on the outer surface of the flexible hinged beam 4. The angle between them is 90°. Fiber Bragg grating 3 is encapsulated with 502 glue or epoxy resin glue in fiber installation groove b. The grating part of fiber Bragg grating 3...

Embodiment 3

[0034] In this embodiment, the circumferential direction of the flexible hinge beam 4 is processed with a measuring groove a, the cross-sectional geometric shape of the measuring groove a is a circular arc, the central angle α of the circular arc is 180°, and the radius of the circular arc is:

[0035] R = L 2 s i n α 2

[0036] In the formula, L is the length of the grid region of the fiber Bragg grating 3, and α is the central angle of the arc. The difference t between the radius of the flexible hinged beam 4 and the depth of the measuring groove a is 1.5mm. Two optical fiber installation grooves b are machined on the outer surface of the flexible hinged beam 4 along the axial direction. The angle between them is 90°. Fiber Bragg grating 3 is encapsulated with 502 glue or epoxy resin glue in fiber in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com