Infrasound and low-frequency sound sensor for monitoring fluid leakage in high-pressure pipeline

A technology of acoustic sensors and high-pressure pipelines. It is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, and pipeline systems. Problems such as low-frequency acoustic signal and unfavorable device stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

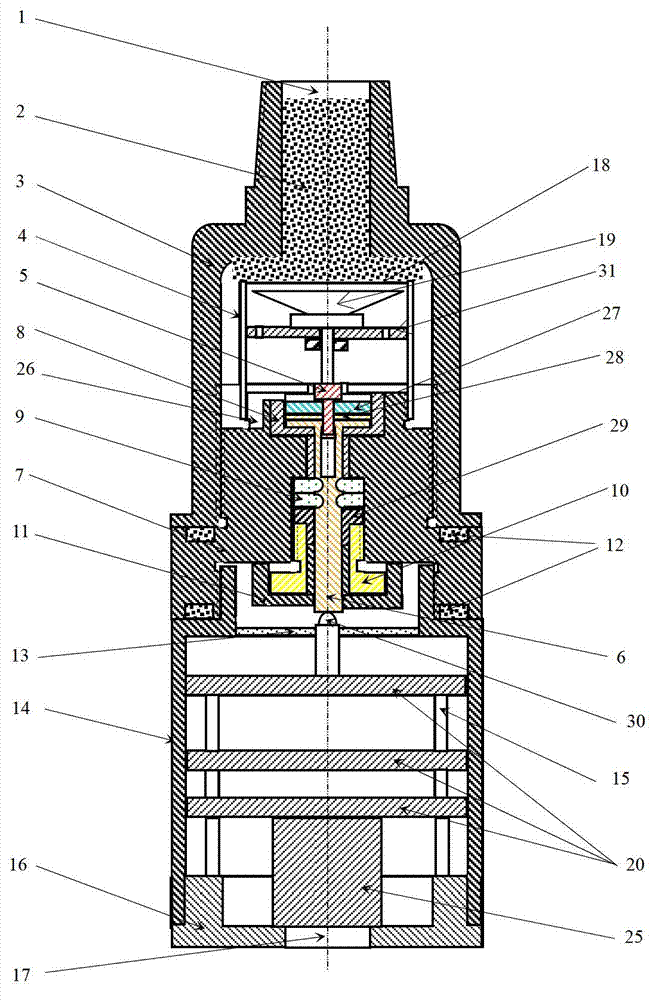

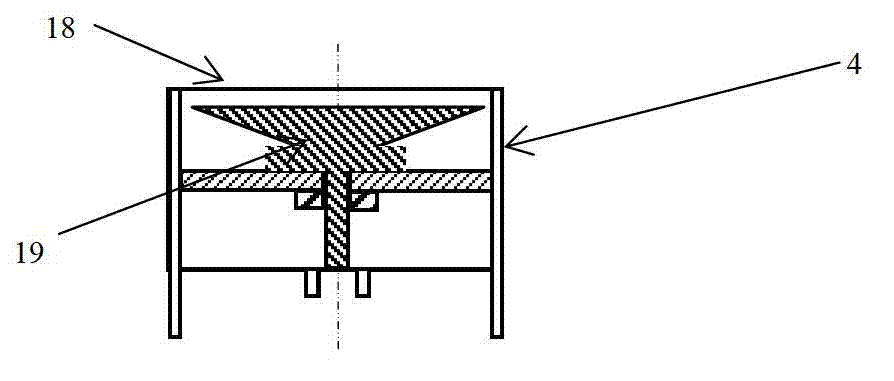

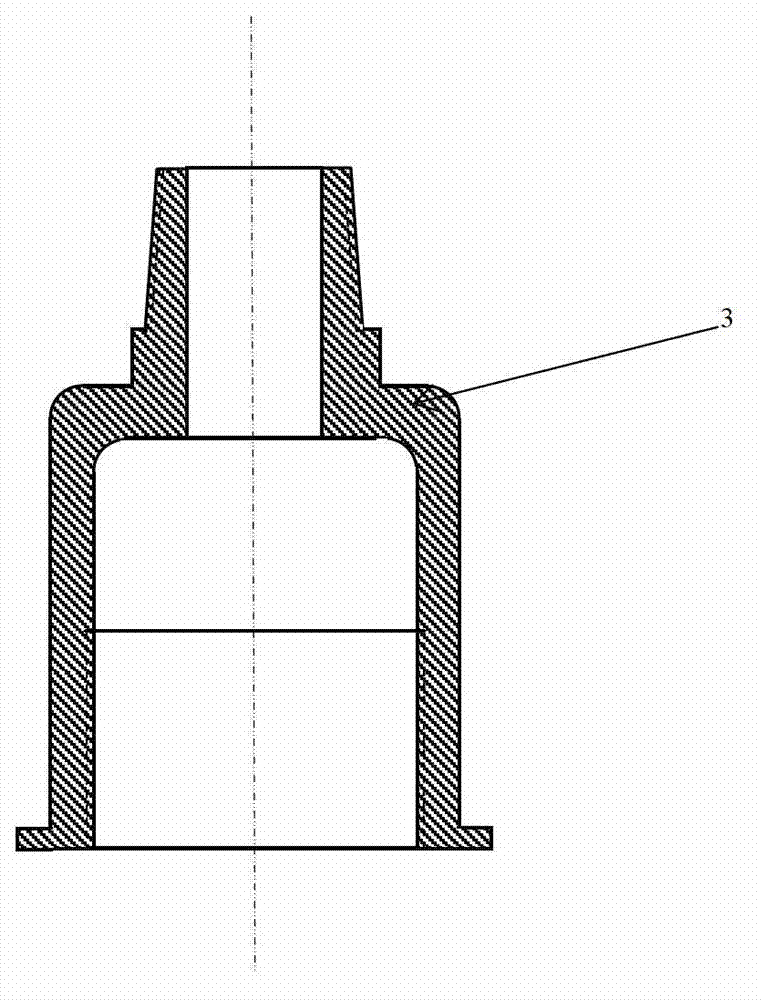

[0071] This embodiment is a kind of infrasound and low-frequency acoustic sensor used for leak detection of high-pressure natural gas pipeline, such as figure 1 As shown, the infrasound and low-frequency sound sensor includes a pressure-resistant front chamber 3 for placing a sensor capable of measuring infrasound and low-frequency sound waves, a sensor base 7 , an instrument box 14 for placing a signal detection circuit board, and an instrument box bottom cover 16 . The capacitive sensor 4 is tightly connected to the sensor base 7 through its bottom thread to form a whole, and then is tightly connected to the pressure-resistant front chamber 3 through the side thread of the sensor base 7, and the pressure-resistant front chamber 3 and the sensor base 7 create a high pressure environment.

[0072] The instrument box 14 is tightly connected with the sensor base 7 through threads, and the bottom cover 16 of the instrument box is tightly connected with the instrument box 14 throu...

Embodiment 2

[0078] The structure of the sensor of this embodiment is basically the same as that of Example 1, except that the fluid in the high-pressure pipeline to be measured becomes a liquid medium such as petroleum, and the front measuring part of the infrasound and low-frequency sound measurement sensor is structurally changed, that is, the example The sponge filter 2 in 1 is transformed into a sound-permeable isolator 24, such as Figure 17 As shown, and the interior of the front cavity is filled with sound-transparent liquid, which ensures that the leakage signal transmitted in the high-pressure pipeline can be sensitive to the infrasound and low-frequency sound measurement sensors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com