Negative-type photosensitive resin composition, photocuring pattern formed by using the same and image display device

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve the problems of whitening and reduced developability, and achieve excellent adhesion, excellent low temperature curing, excellent heat resistance and chemical resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0149] Production example 1. Synthesis of alkali-soluble resin (first resin)

[0150] In a 1L flask equipped with a reflux cooler, a dropping funnel, and a stirrer, nitrogen was flowed in at 0.02L / min to form a nitrogen atmosphere, 300 parts by weight of methyl ethyl diglycol was charged, and heated to 70°C while stirring. ℃. Next, 20 parts by weight of norbornene, 30 parts by weight of styrene, 45 parts by weight of methacrylic acid, 3-acryloyloxy-2-hydroxypropyl methacrylate (3-Acryloyloxy-2- 135 parts by weight of hydroxypropyl methacrylate) were dissolved in 140 parts by weight of methyl ethyl diglycol to prepare a solution.

[0151] Using a dropping funnel, the produced solution was dropped into a flask kept at 70° C. over 4 hours. On the other hand, 30 parts by weight of the photopolymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) was dissolved in methyl ethyl diglycol 225 over a period of 4 hours using another dropping funnel. The solution in parts by we...

manufacture example 2

[0153] Production Example 2. Synthesis of Alkali-soluble Resin (Second Resin)

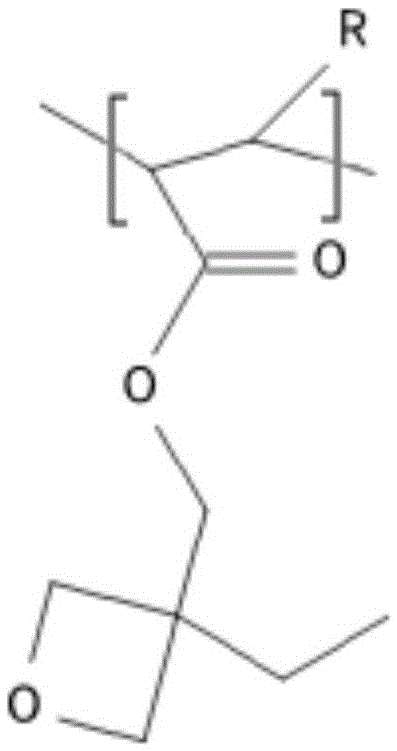

[0154]A 1 L flask equipped with a reflux cooler, a dropping funnel, and a stirrer was made into a nitrogen atmosphere, 300 parts by weight of methyl ethyl diglycol was charged, and it heated to 70 degreeC, stirring. Next, 300 parts by weight of a mixture of the following chemical formula 4 and chemical formula 5 (the molar ratio is 50:50), (3-ethyloxetan-3-yl) methyl methacrylate ((3-ethyloxetan - 150 parts by weight of 3-yl)methyl methacrylate) and 50 parts by weight of methacrylic acid were dissolved in 140 parts by weight of methyl ethyl diglycol to prepare a solution.

[0155] [chemical formula 4]

[0156]

[0157] [chemical formula 5]

[0158]

[0159] The produced solution was dropped into a flask kept at 70° C. using a dropping funnel over 4 hours. On the other hand, 30 parts by weight of the photopolymerization initiator 2,2'-azobis(2,4-dimethylvaleronitrile) was dissolved in met...

manufacture example 3

[0161] Production Example 3. Synthesis of Alkali-Soluble Resin (A-3)

[0162] Except that no norbornene (norbornene) was added, an alkali-soluble resin was produced in the same manner as in Production Example 1 above, and a copolymer having a solid content of 35.5% by weight and an acid value of 123.7 mg KOH / g (solid content conversion) was obtained ( A-3) solution.

[0163] At this time, the weight average molecular weight of the resin was 15,000, and the molecular weight distribution (Mw / Mn) was 2.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com