A Method for Determining the Optimal Arc Edge of Space Regular Polygon Plane Thin Film Structure

A regular polygon and film structure technology, which is applied in the field of determining the optimal arc edge of a space regular polygon plane film structure, can solve the problems such as the inability to guarantee the maximum effective area without wrinkles, and the quantitative analysis of the cutting shape of the arc edge is not given.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

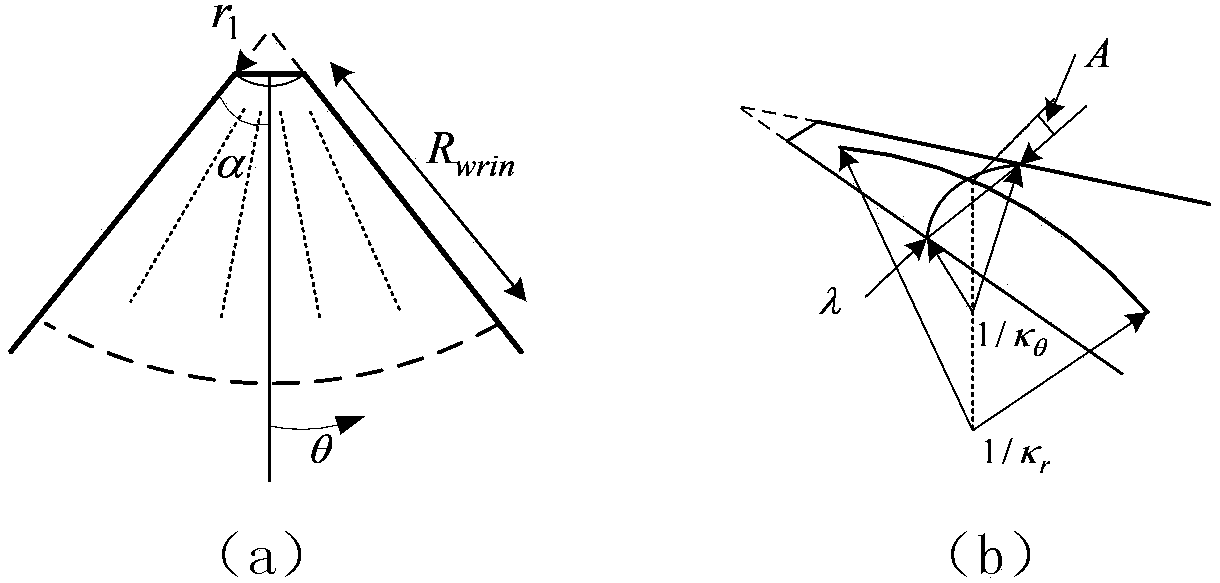

[0106] The invention provides a method for determining the optimal arc edge of a space regular polygon planar film structure, comprising the following steps and contents:

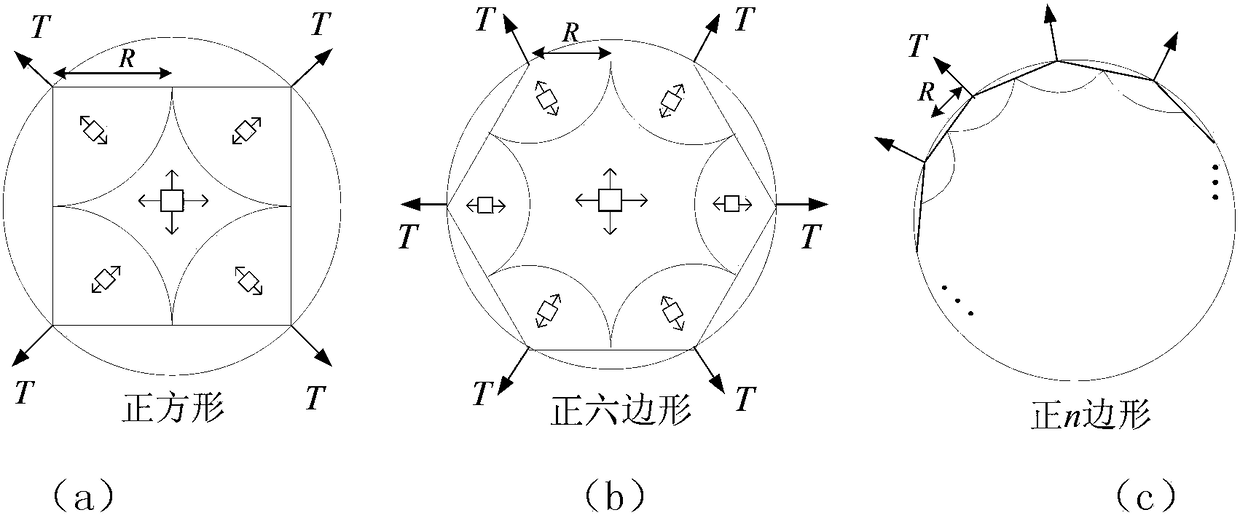

[0107] (1) Determination of the radius of the wrinkled region when the regular polygonal membrane structure is subjected to an equivalent angular tension

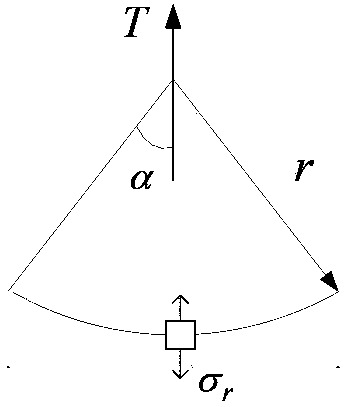

[0108] for figure 1 As shown in the traditional stress field hypothetical model, the circumcircle radius is R m , its inscribed regular polygonal film structure is an isotropic linear elastic body, half of the side length is R, the number of sides of the regular polygon is n, Young's modulus is E, Poisson's ratio is v, when subjected to When the equivalent angular tension T is applied, the corner area is only subject to radial stress, and the central area is subject to uniform bidirectional stress. According to the judgment condition of the wrinkle state, when the second principal stress is negative in the corner region subjected to unidirectional stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com