Rotating mechanical equipment virtual assembly model and method based on context awareness

A technology for rotating mechanical equipment and virtual assembly, which is applied in design optimization/simulation, special data processing applications, instruments, etc., and can solve problems such as difficulty in determining the density radius and large computational load of hierarchical clustering algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] For the application of the assembly model of the present invention, the following describes the assembly process of parts as an example, which specifically includes the following steps:

[0134] Step A: Construct various part models required by the virtual assembly task, establish a three-dimensional model of the part, and calibrate the coordinate set of the feature points that describe the feature of the part;

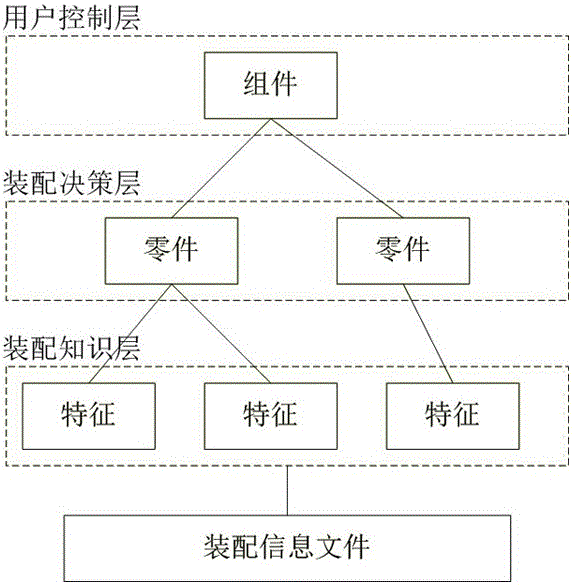

[0135] Step B: Construct a virtual assembly model, and establish a virtual assembly model according to the features of the part, the parameters of the features and the assembly process; the following example shows a virtual assembly model:

[0136] Component 1 ={{trans-x,trans-y,trans-z},{Part 1 }}

[0137] ...

[0138] Component 7 ={{trans-x,trans-y,trans-z},{Part 7 }}

[0139] Part 1 ={Runner body shell,[Feature1,Feature 2 ....Feature 16 ]}

[0140] Part 2 ={paddle 1,[Feature 17 ,Feature 18 ,Feature 19 }

[0141] ...

[0142] Part 6 ={Under the rack,[Feature 29 ,Feature 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com