Switchgear for short circuit arc extinguishing for low voltage, medium voltage or high voltage

A switchgear, medium voltage technology, applied in electrical switches, closed switches, explosion switches, etc., can solve the problems of failure and loss of short-circuit devices, and achieve the effects of preventing rebound, increasing the pressure of the cylinder, and increasing the range of shape selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

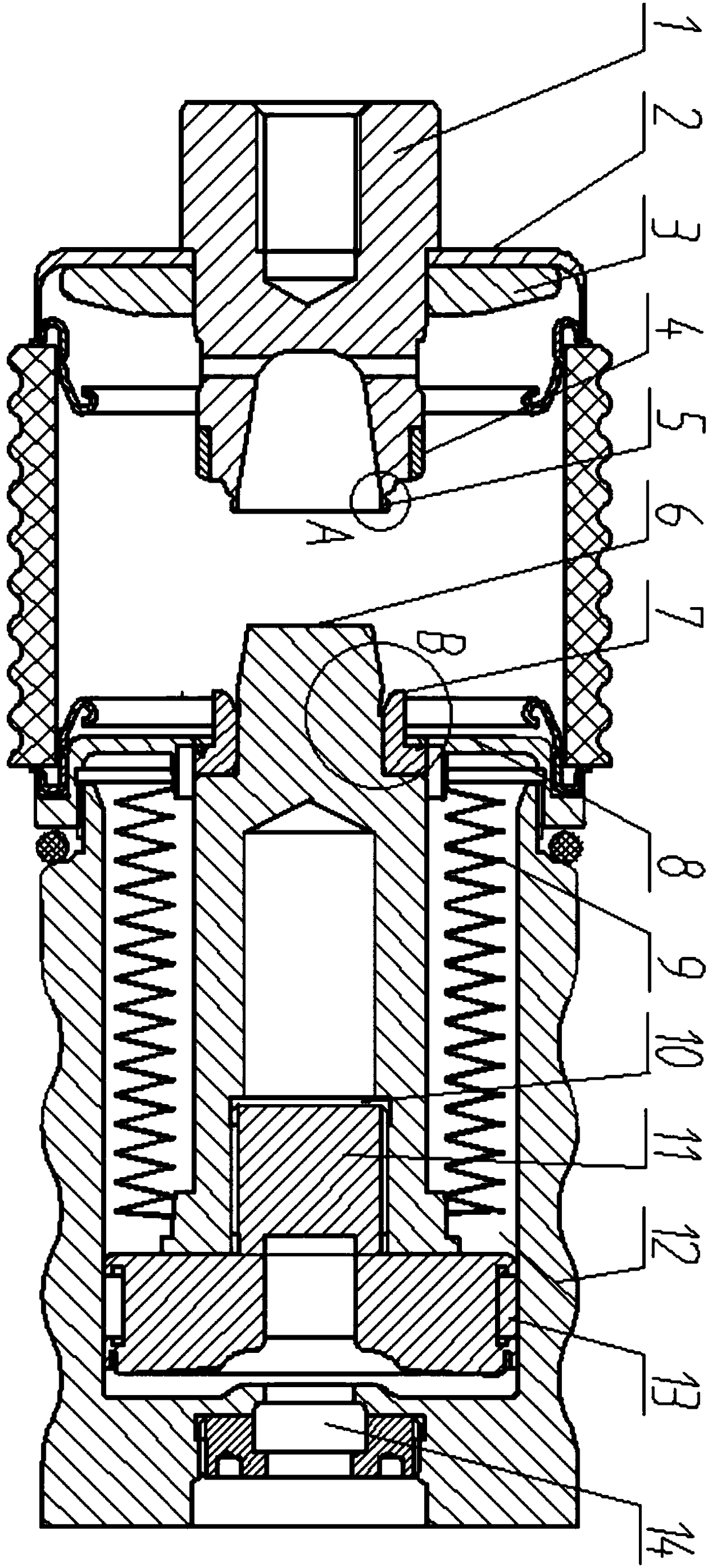

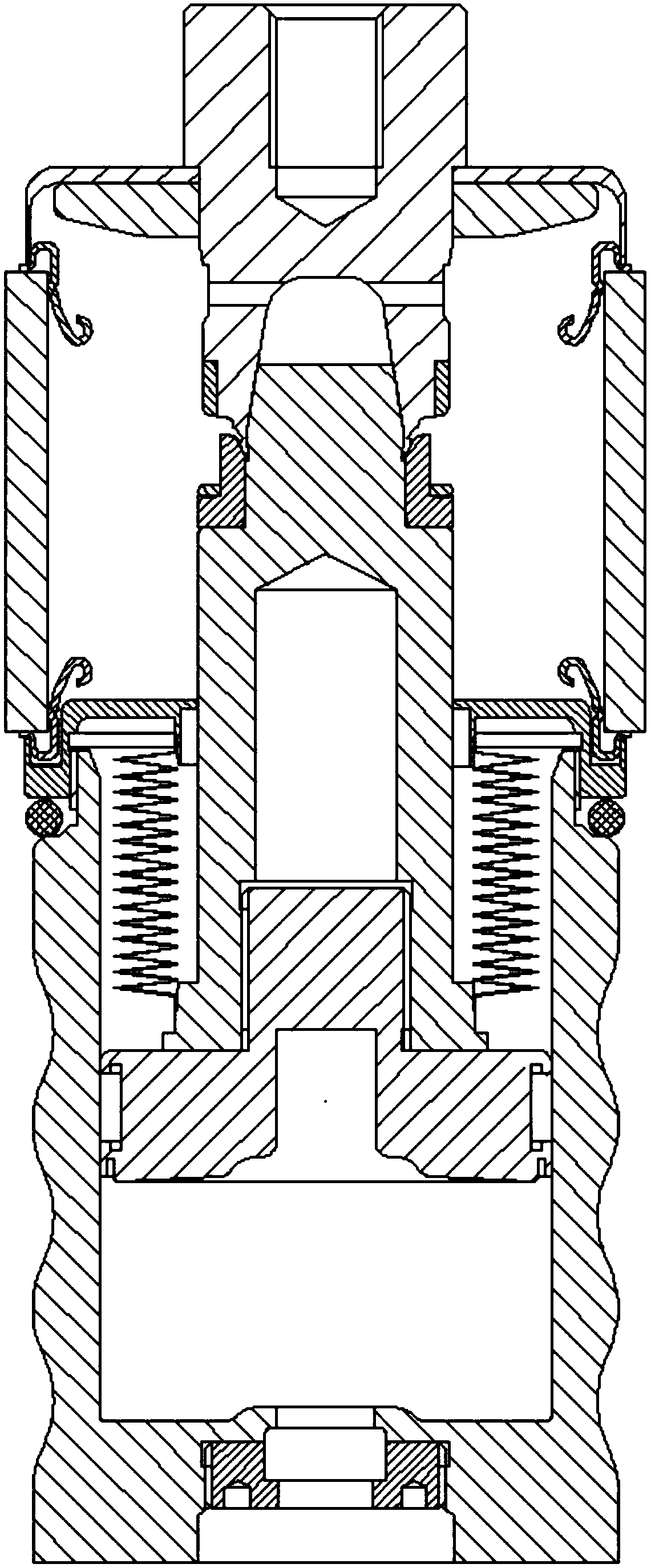

[0041] A switchgear for low-voltage, medium-voltage or high-voltage short-circuit arc extinguishing, including a housing 2, the two ends of the inner cavity of the housing 2 are respectively provided with a static contact 1, a cylinder 12, a piston 11 is provided in the cylinder 12, and the bottom of the cylinder 12 A gas generator 14 is provided, the front end of the piston 11 is provided with a movable contact 6, the piston 11, the cylinder 12 and the movable contact 4 are electrically connected, and the piston is also provided with a movable contact finger 13 to ensure that the piston 11 is in the process of moving. Fully electrically connected with the cylinder 12, an O-ring 10 is also provided between the piston and the moving contact, one end of the bellows 9 is airtightly connected with the energy storage acceleration shear plate 8 set on the inner wall of the housing, and the other end of the bellows 9 It is airtightly linked with the rear end of the moving contact 6, a...

Embodiment 2

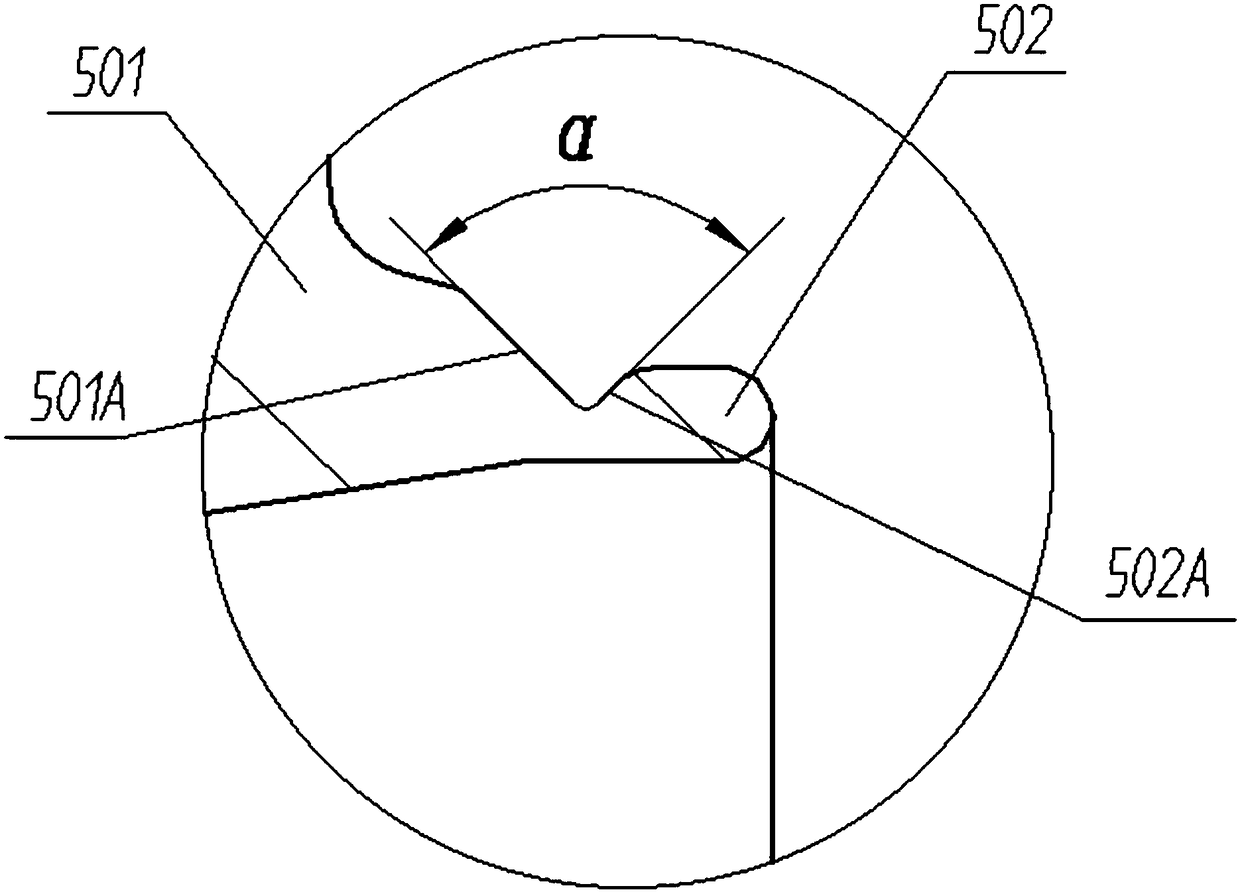

[0046] The difference from Example 1 is that the end of the static contact 1 is provided with a spherical opening, and the front end of the moving contact 6 is provided with a ball head complementary to the spherical opening, the angle β is preferably 5°, and the angle α is preferably is 60°.

[0047] Example 2

[0048] The difference from Embodiment 1 is that the end of the static contact 1 is provided with a cylindrical opening, the front end of the moving contact 6 is provided with a column head complementary to the cylindrical opening, the opening end of the static contact and the column head end of the moving contact All parts are chamfered, the cylindrical opening of the static contact is provided with conductive static contact fingers, the β angle is preferably 15°, and the α angle is preferably 120°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com