Device and method for monitoring deposition thickness of polysilicon furnace tube

A furnace tube deposition and monitoring device technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of inconsistent film thickness on the surface of the wafer, difference in thickness of polysilicon film, and decline in product yield, so as to avoid Inconsistent film thickness, reduced monitoring costs, and reduced measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

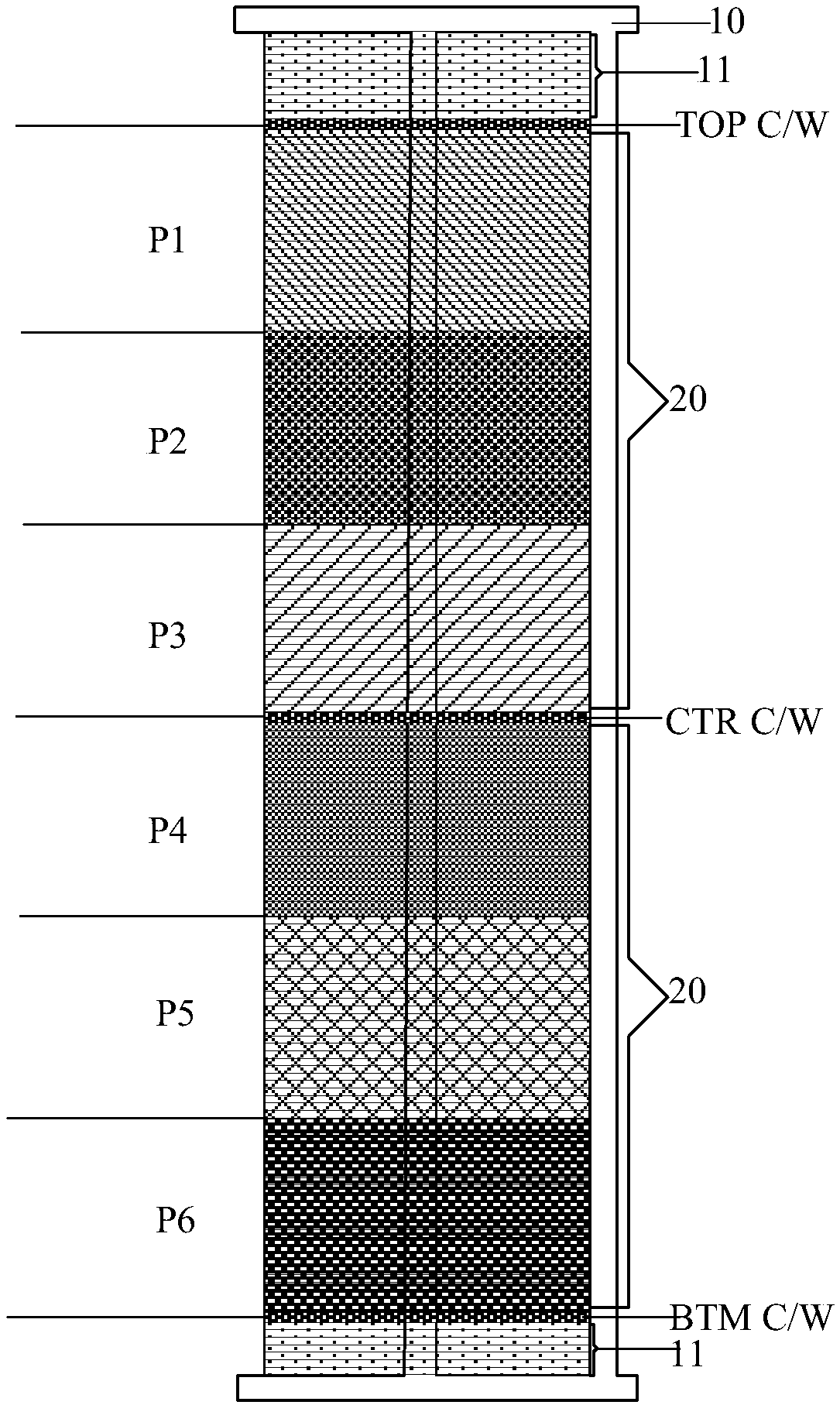

[0035] Please refer to figure 2 , the present embodiment proposes a polysilicon furnace tube deposition film thickness monitoring device, including: a crystal boat 10, a top control chip TOP C / W, a middle control chip CTR C / W, a bottom control chip BTM C / W and A number of product wafers 20 to be polysilicon deposited. Wherein, the top of the wafer boat 10 is loaded with the top control plate TOP C / W, the middle is loaded with the middle control plate CTR C / W, the bottom is loaded with the bottom control plate BTM C / W, and the polycrystalline silicon deposition Product wafers 20 correspondingly fill the wafer boat loading areas P1, P2, P3 between the top control plate TOP C / W and the middle control plate CTR C / W and the middle control plate CTR C / W and the middle control plate CTR C / W In the wafer boat loading areas P4, P5, and P6 between the bottom control plate BTM C / W, the surfaces of the top control plate TOPC / W and the middle control plate CTR C / W are all annealed, and t...

Embodiment 2

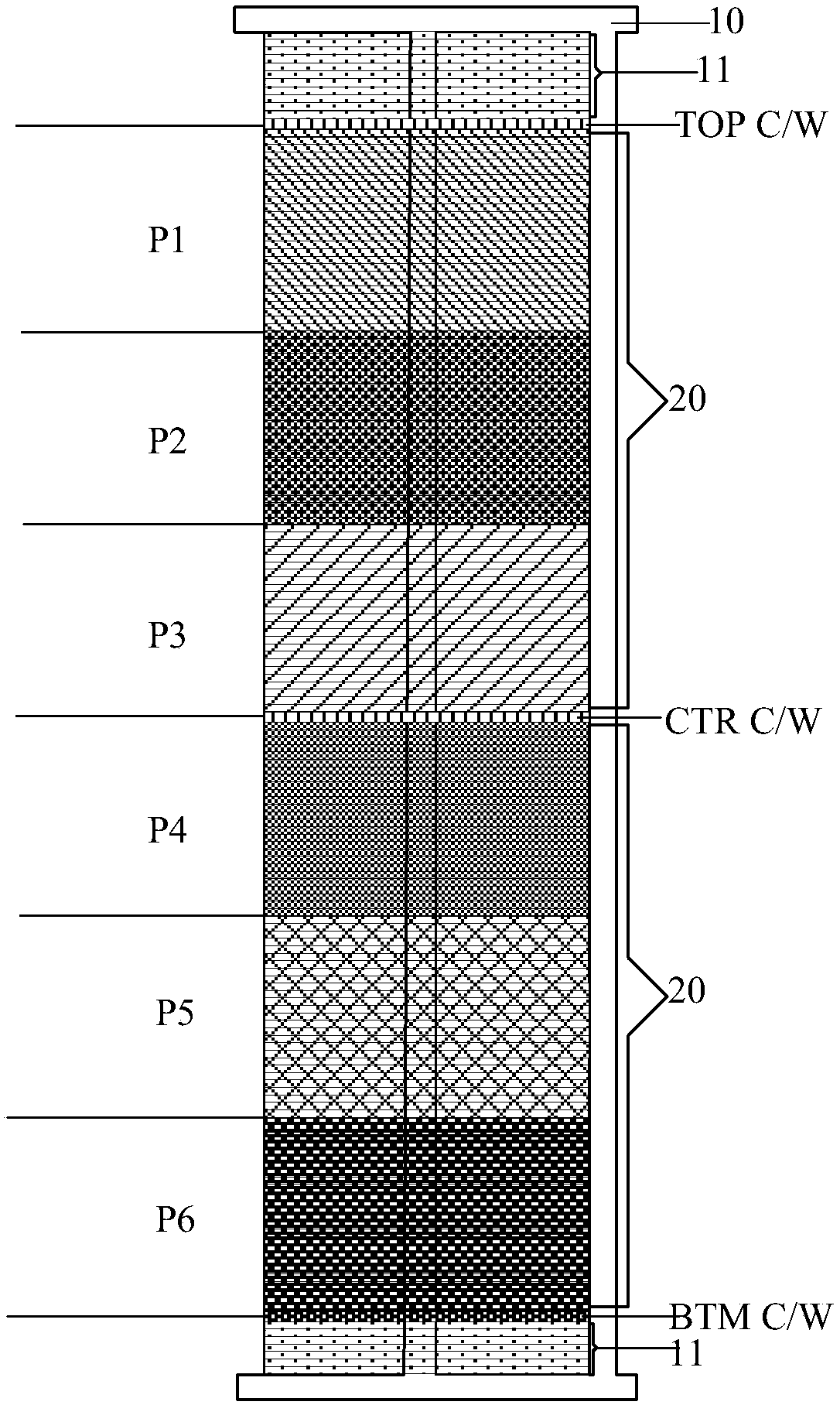

[0045] Please refer to image 3 , the present invention proposes a polysilicon furnace tube deposition film thickness monitoring device, comprising: a crystal boat 10, an upper top control chip TOP C / W1, a lower top control chip TOP C / W2, a middle control chip CTR C / W, a Bottom control chip BTM C / W and several product wafers 20 to be polysilicon deposited. Wherein, the top of the wafer boat 10 is loaded with the upper top control sheet TOP C / W1 and the lower top control sheet C / W2, and the upper top control sheet TOP C / W1 and the lower top control sheet TOP C / W2 are placed next to each other, and the middle part is loaded with The middle control piece CTR C / W, the bottom control piece BTM C / W is loaded on the bottom, and the product wafer 20 to be polysilicon deposited is correspondingly filled in the lower top control piece TOP C / W2 and the middle The wafer boat loading areas P1, P2, P3 between the control plate CTR C / W and the wafer loading area P4, P5, P6 between the middl...

Embodiment 3

[0052] Please refer to Figure 4 , the present invention proposes a polysilicon furnace tube deposition film thickness monitoring device, comprising: a crystal boat 10, a top control chip TOP C / W, an upper middle control chip CTR C / W1, a lower middle control chip CTR C / W2, a bottom Control the BTM C / W and several product wafers 20 to be polysilicon deposited. Wherein, the top of the wafer boat 10 is loaded with the top control sheet TOP C / W, the middle is loaded with the upper middle control sheet CTR C / W1, the lower middle control sheet CTR C / W2, and the upper middle control sheet CTR C / W1, The lower middle control piece CTR C / W2 is placed next to each other, and the bottom control piece BTM C / W is loaded on the bottom, and the product wafer 20 to be deposited with polysilicon is correspondingly filled in the top control piece TOP C / W and the upper control piece BTM C / W. The wafer boat loading areas P1, P2, P3 between the middle control plate CTR C / W1 and the wafer boat load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com