Cylindrical battery pack

A technology for cylindrical batteries and battery packs, applied to battery pack components, secondary batteries, circuits, etc., which can solve problems such as battery performance degradation, inability to effectively remove battery heat, and impact on battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

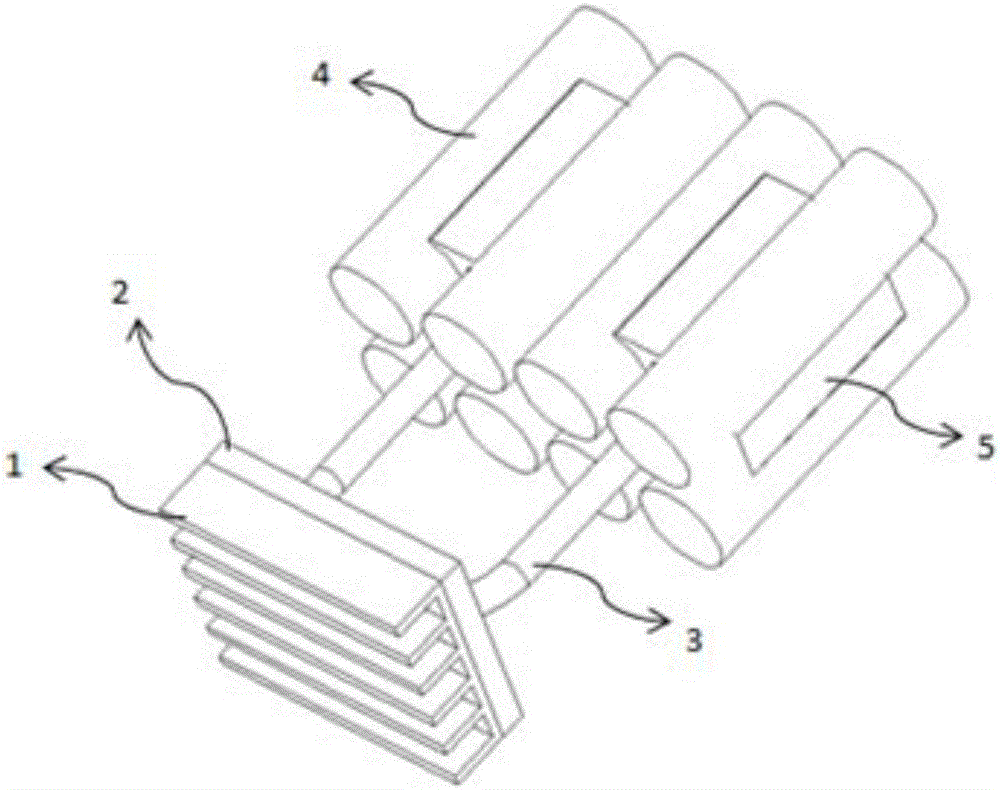

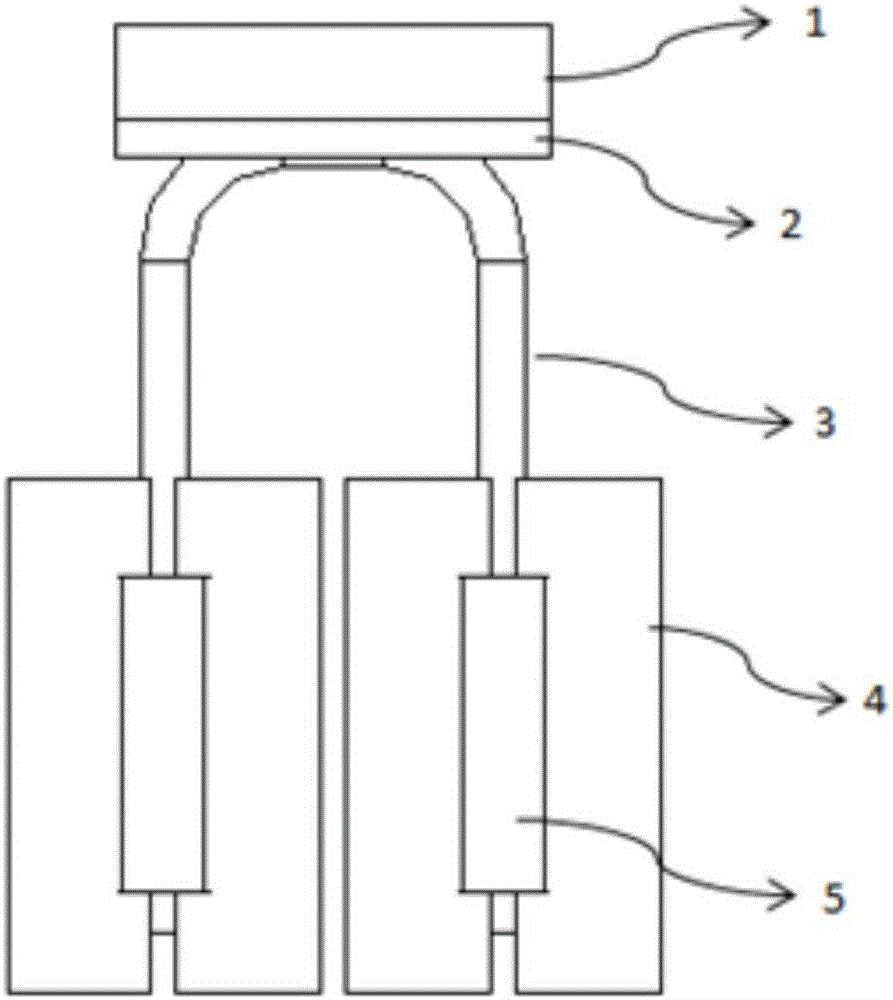

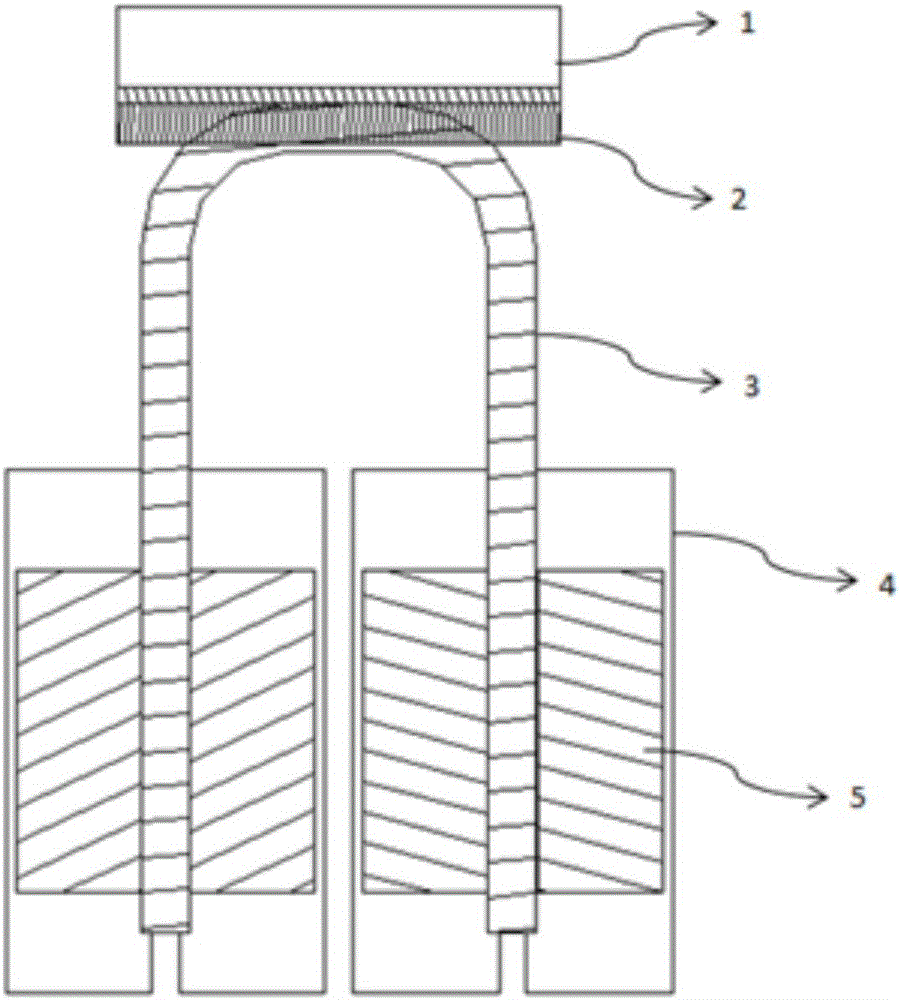

[0019] Please refer to Figure 1 to Figure 8 As shown, the cylindrical battery pack of the present invention includes a heat sink 1 , an aluminum substrate 2 , a heat pipe 3 , a cylindrical battery 4 and a heat dissipation support 5 . The shape of the cylindrical battery 4 is cylindrical, the outer layer is wrapped by an insulating film, and the two ends are positive tabs and negative tabs respectively. The heat dissipation bracket 5 is made of industrial pure aluminum, which not only has good thermal conductivity but also has certain hardness. The outer surface of the heat dissipation bracket 5 is evenly spaced to form a plurality of grooves 50 for placing the cylindrical battery 4. The function of the grooves 50 is to position the cylindrical battery 4, and the second is the heating surface and the groove of the cylindrical battery 4. 50 are closely fitted, which is beneficial to the heat dissipation of the cylindrical battery 4 . As a further improvement of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com