Improving the heat shrinking process and heat shrinking device of the wavy edge of the diaphragm

A wavy edge and thermal shrinkage technology, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of oversize, poor diaphragm diaphragm wave, and increased production costs of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

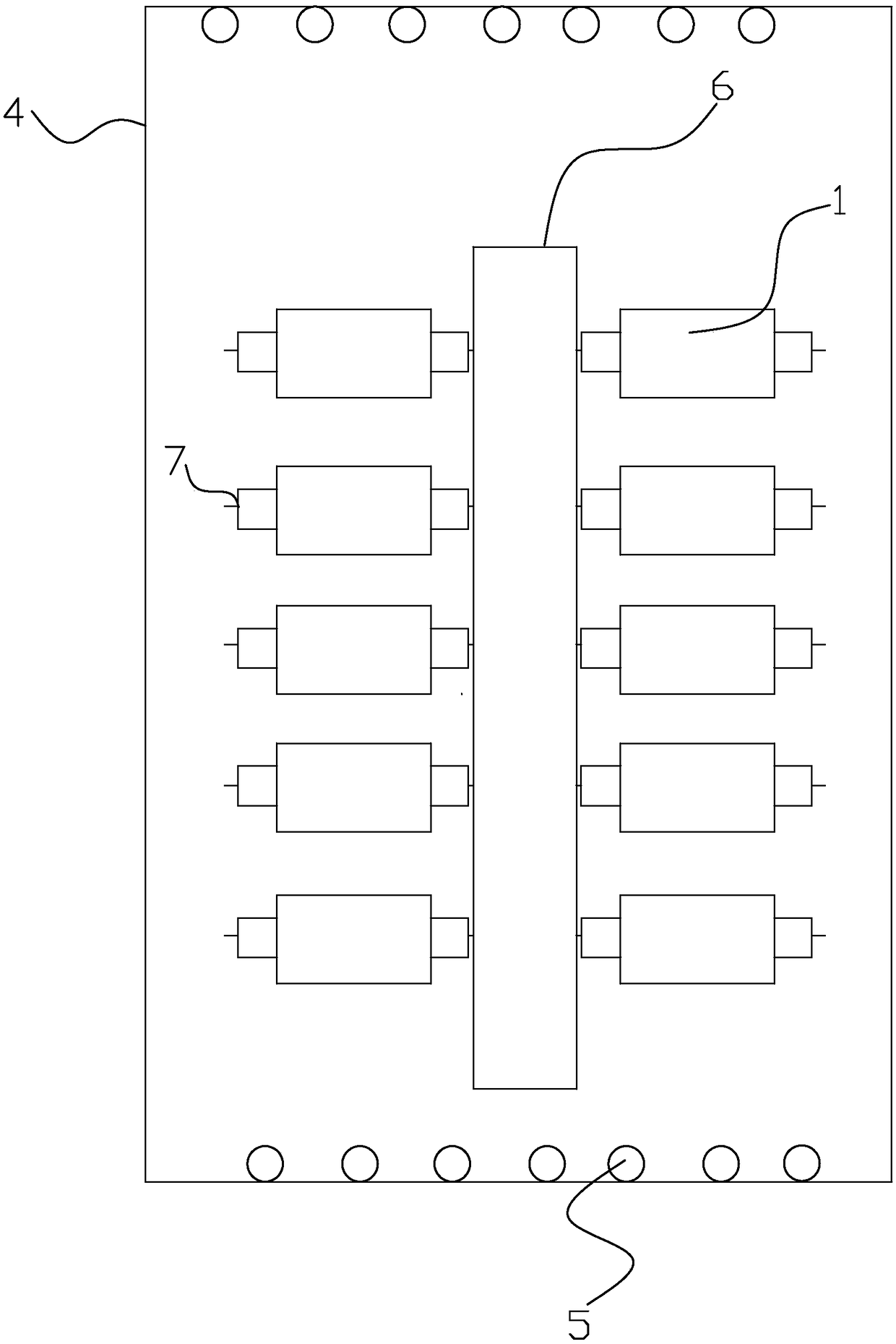

[0028] A thermal shrinkage process for improving the wavy edge of a diaphragm, comprising the following steps:

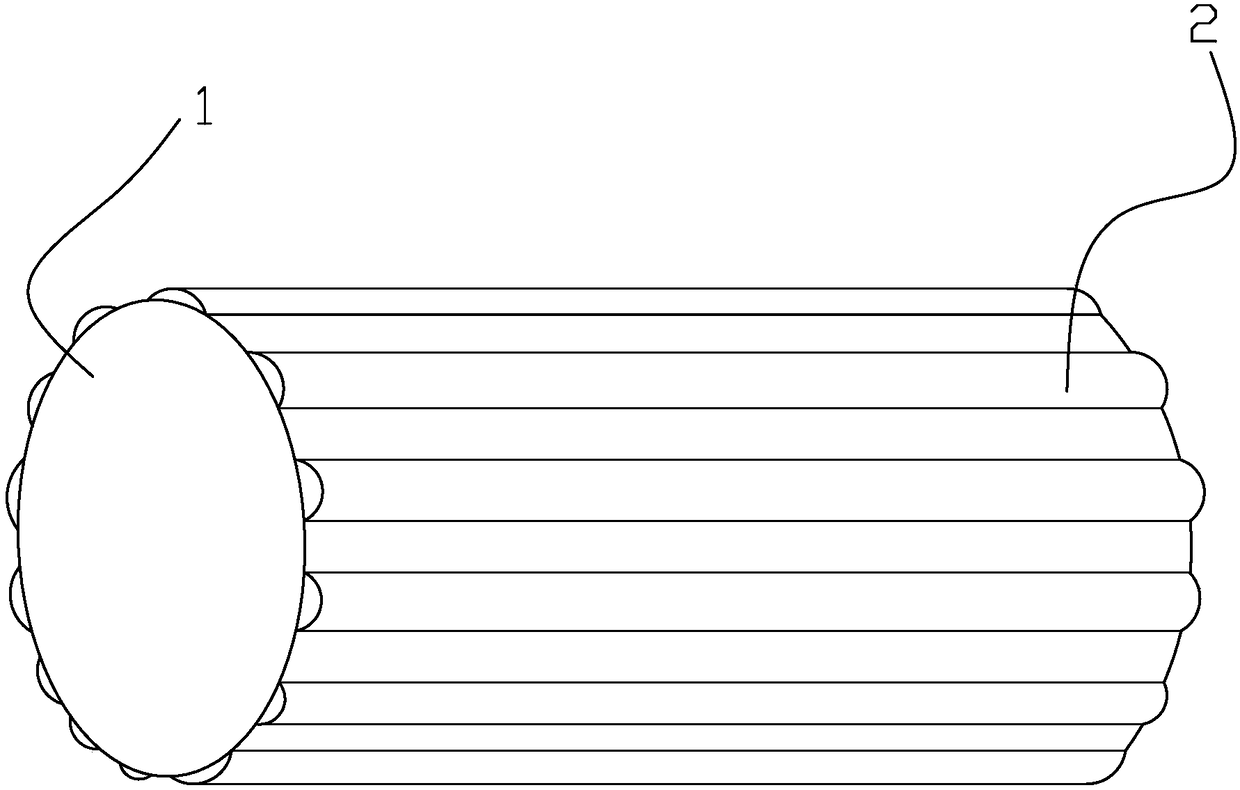

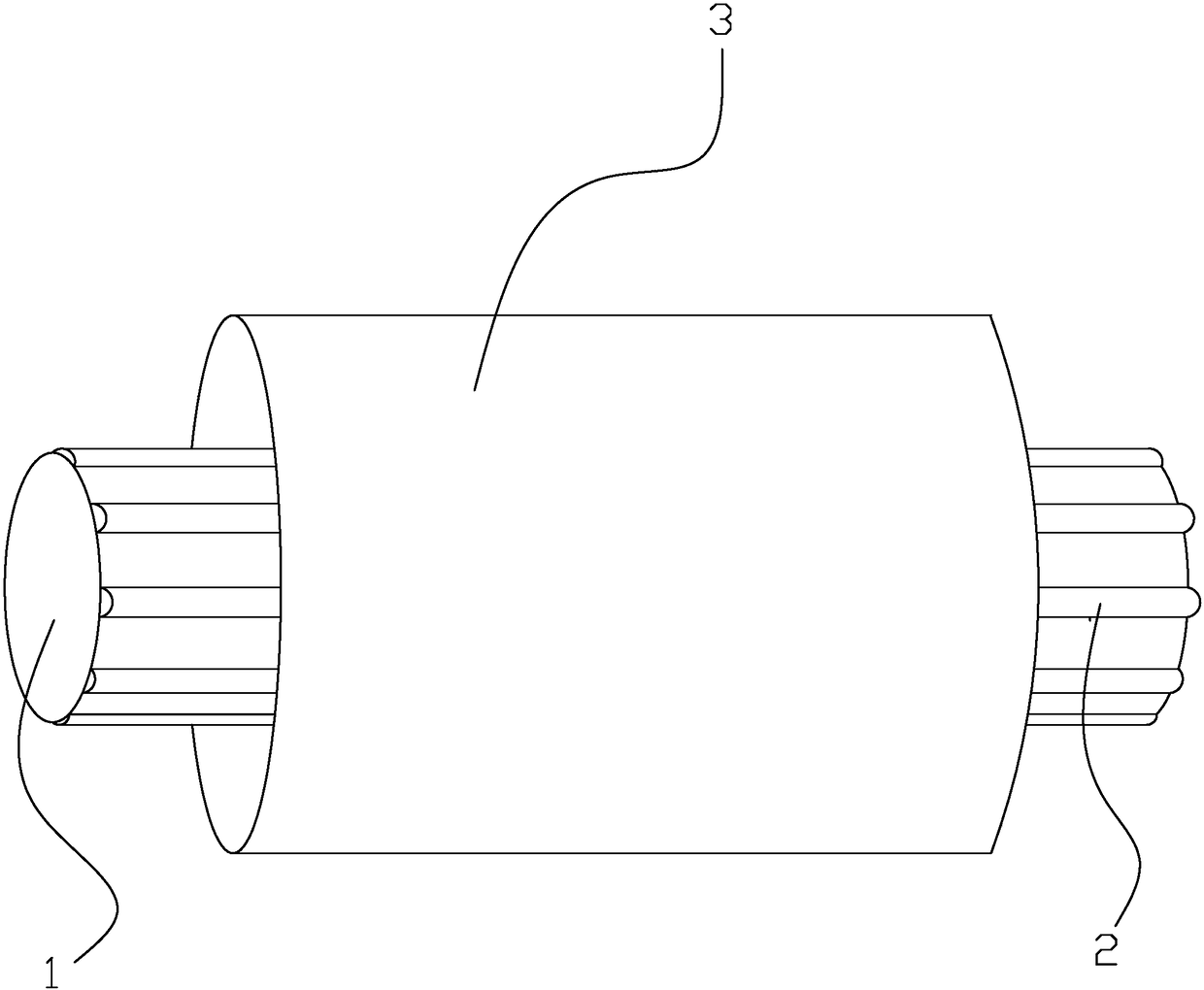

[0029] (1) Prepare the rewinding roller, arrange a plurality of buffer strips that can provide shrinkage space for the diaphragm wound on the rewinding roller at equal intervals on the outer surface of the rewinding roller, and each buffer strip is parallel to the axial direction of the rewinding roller, The buffer strip protrudes from the outer surface of the rewinding roller. The length of the buffer strip is greater than the width of the diaphragm;

[0030] (2) Winding the diaphragm onto the rewinding roller 1 provided with buffer strips;

[0031] (3) Bake the rewinding roll wound with the diaphragm at a certain temperature and keep it for a certain period of time. When baking, set the temperature at 40-60°C and keep it for 20-30 hours. Preferably, when baking , set the temperature to 50°C and keep it for 24h;

[0032] (4) The diaphragm after baking is taken o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com