Mechanical peeling technology of sweet corn of 'Huazhen' variety

A technology of sweet corn and varieties, which is applied in the processing technology field of sweet corn mechanical assembly line operation, and can solve the problems of high energy consumption, low labor efficiency, high corn seed damage rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

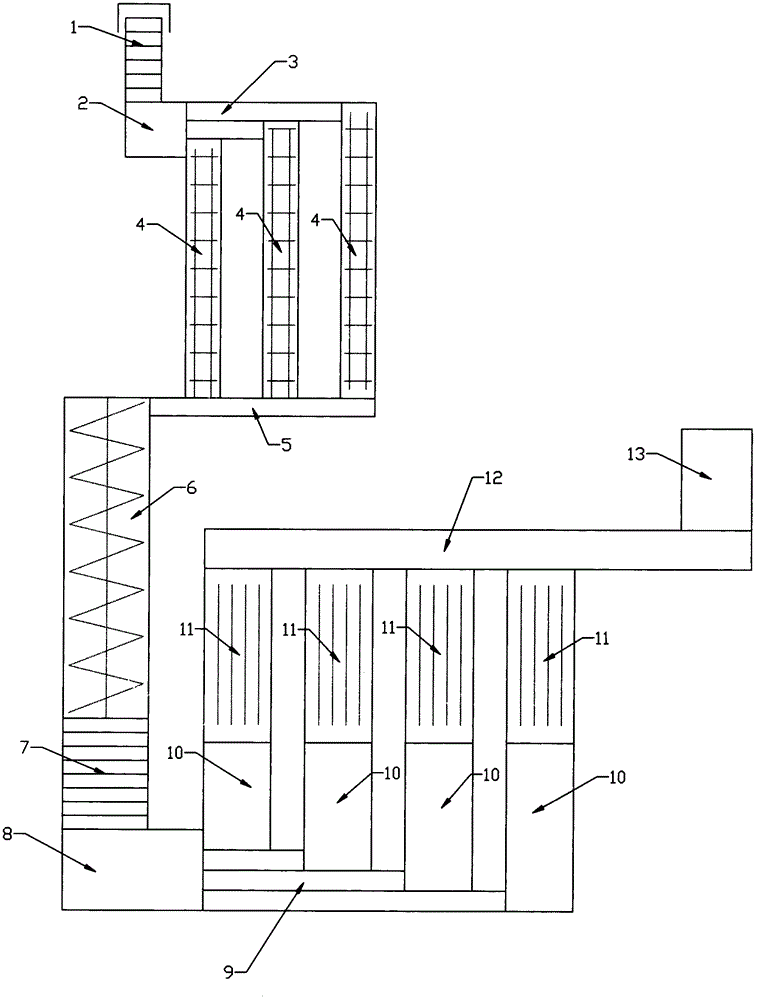

[0007] The operator pours sweet corn of the "Huazhen" variety into the raw material elevator 1, distributes the sweet corn to each sweet corn stalk cutting machine 4 through the raw material vibrating machine 2 and raw material distribution conveyor 3, and puts the sweet corn The fruit stalk is placed on the positioning ring of the head cutting machine so that the rotating blade of the head cutting machine can cut off the fruit stalk of the sweet corn. The sweet corn after the fruit stalk has been removed is collected into the sweet corn spiral blanching machine 6 through the conveyor 5, and the sweet corn is blanched and expanded by high-temperature water higher than 80°C. It only takes a few minutes from the inlet to the outlet to complete the expansion and opening of the sweet corn husk. The sweet corn after expansion and opening is transported to the secondary vibrating machine 8 by the secondary hoist 7, then transported to the raw material tertiary vibrating machine 10 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com