Efficient and refined processing method of Huangshanmei tea

A refined processing and high-efficiency technology, applied in the field of high-efficiency refined processing of Huangshanmei tea, can solve problems such as low production efficiency, restricted refining efficiency, and high operating intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

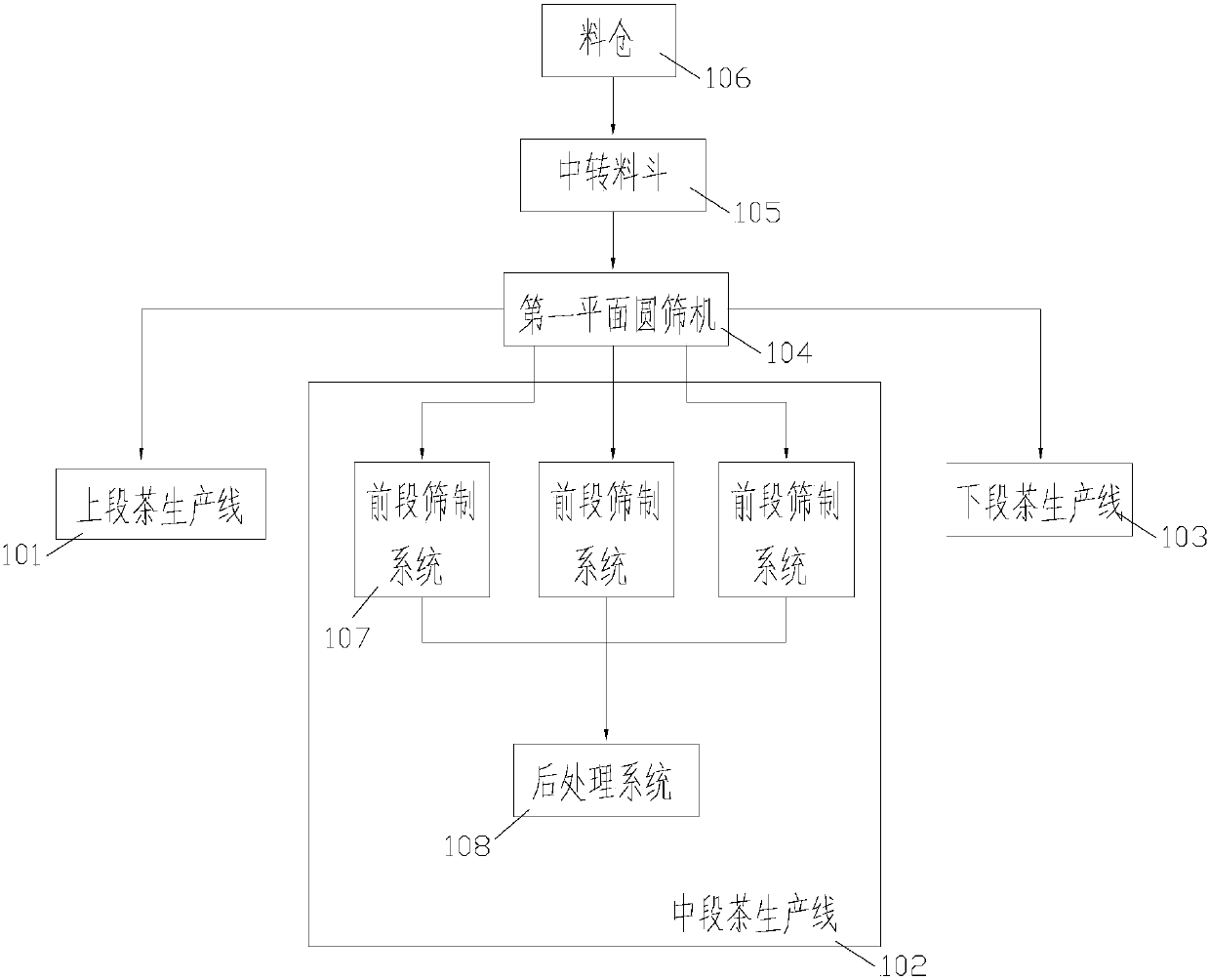

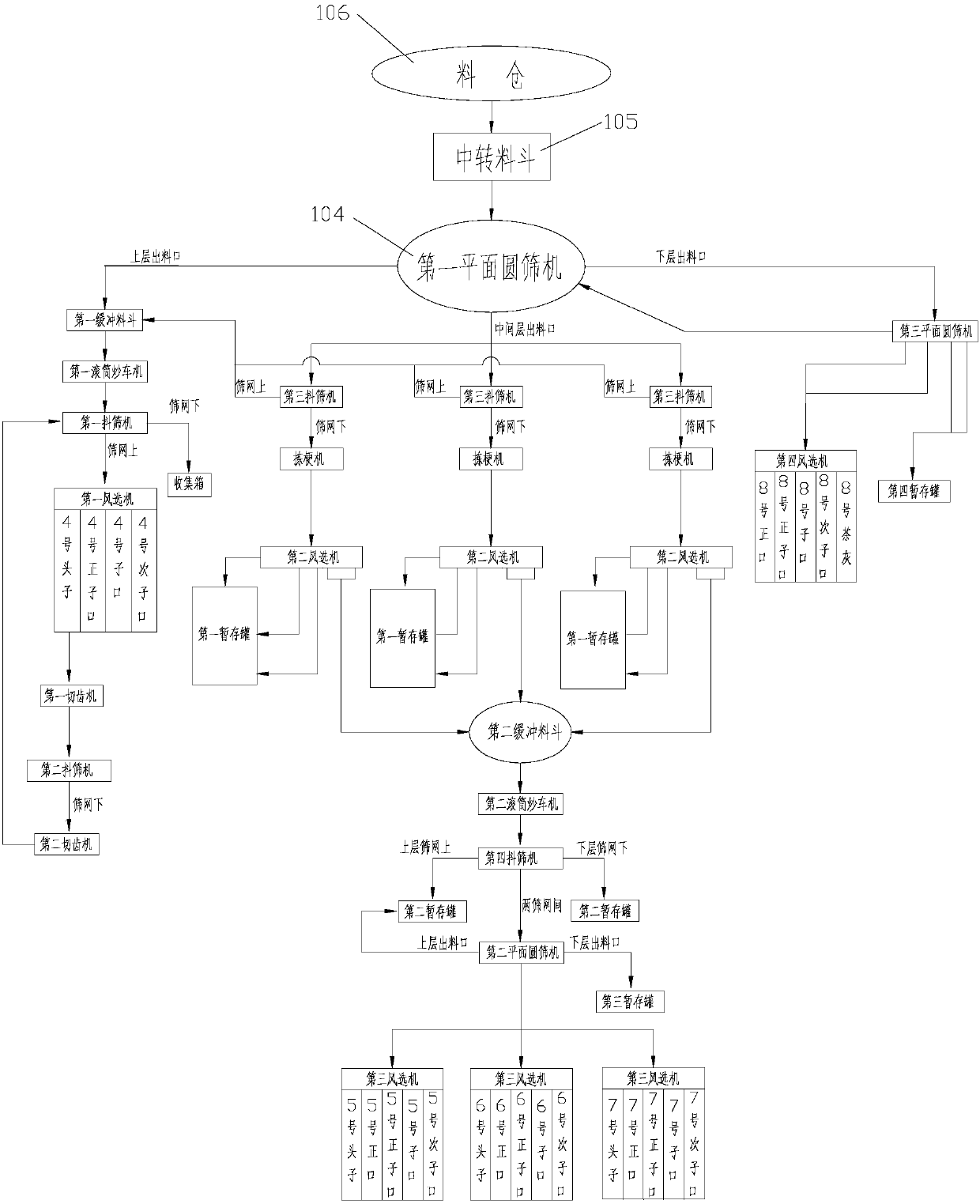

[0051] Please also refer to Figures 1 to 5 , a high-efficiency refining processing method for Huangshanmei tea, which adopts a three-dimensional semi-automatic processing system with mechanized assembly as the main part and manual as the auxiliary. A plane circular sieve machine 104, a transfer hopper 105 arranged between the silo and the first plane circular sieve machine, and an upper segment tea production line 101 connected with the first flat circular sieve machine 104, a middle segment tea production line 102 and a lower segment tea production line Production line 103. The middle-stage tea production line 102 is composed of three sets of front-stage screening systems 107 and post-processing systems 108 .

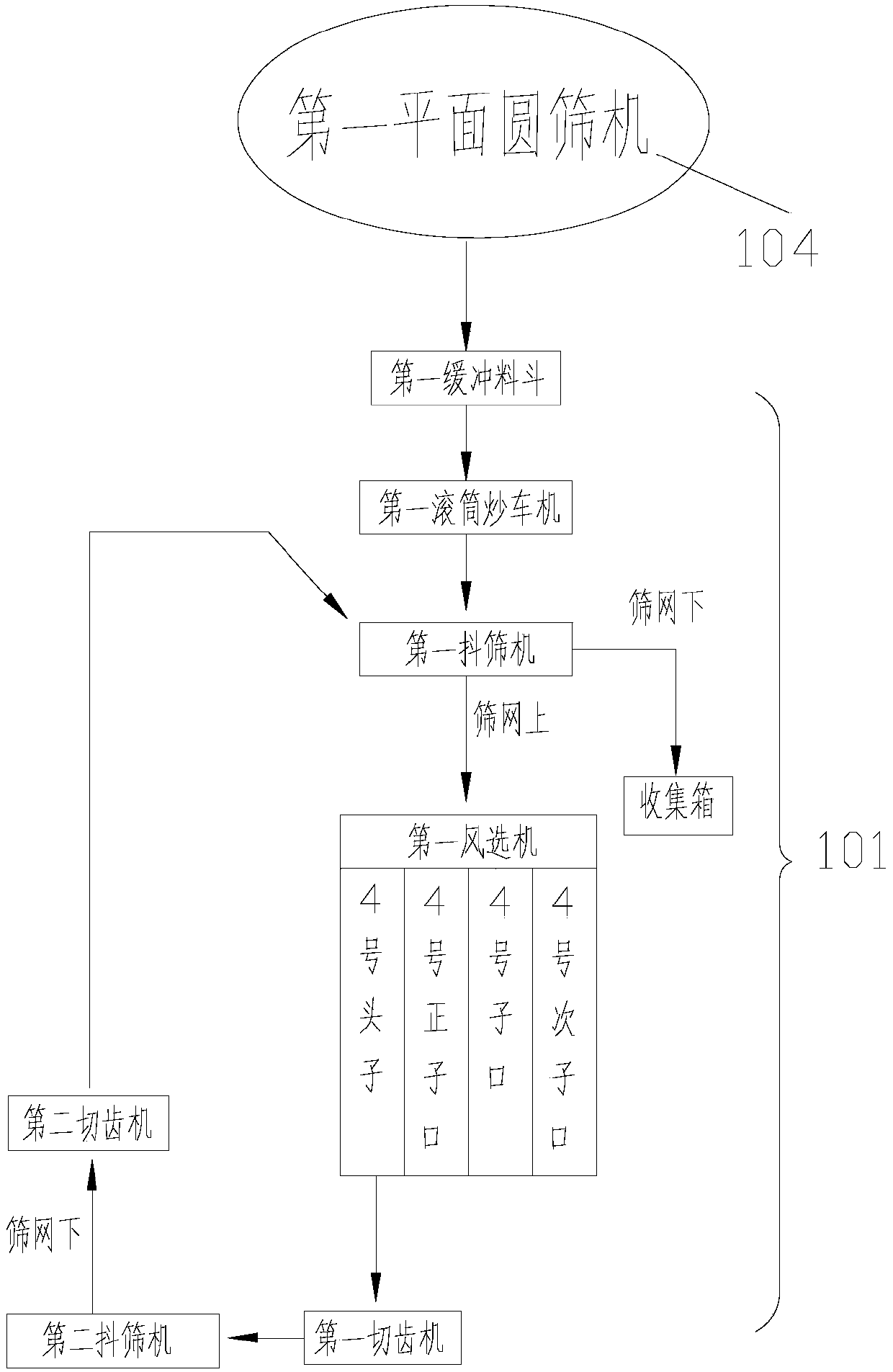

[0052] Among them, the upper stage tea production line 101 is used for refining treatment of 4-hole and above sieve tea, which includes the first buffer hopper, the first drum frying machine, the first shaking sieve machine, the first winnowing machine, the first A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com