Automatic complete equipment for shaping, coating, folding, flattening and arraying in disks of block and particulate sticky foods

A complete set of equipment, folding and pressing technology, applied in the field of production and manufacturing, can solve the problems of large and complex plate placing machines, which are prone to failure, energy consumption, uneven spicing, and inability to load round plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

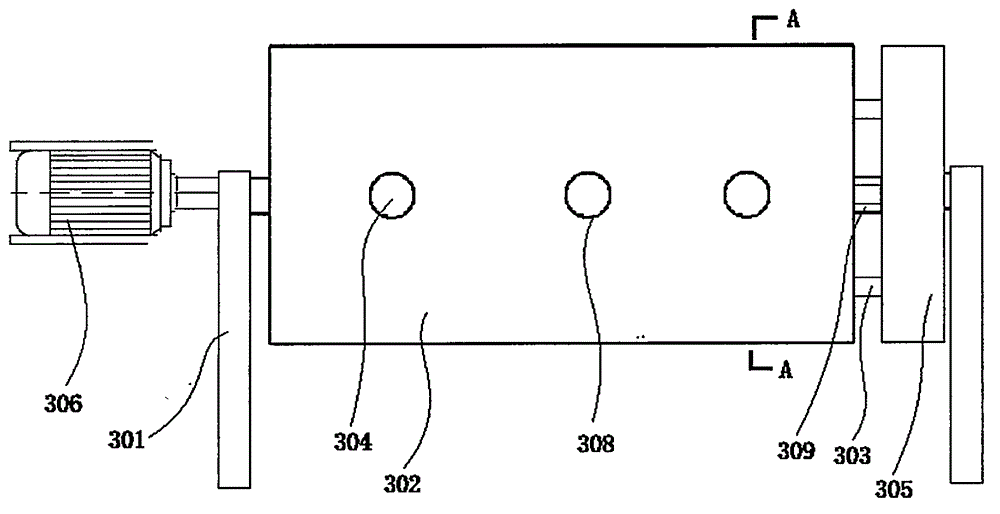

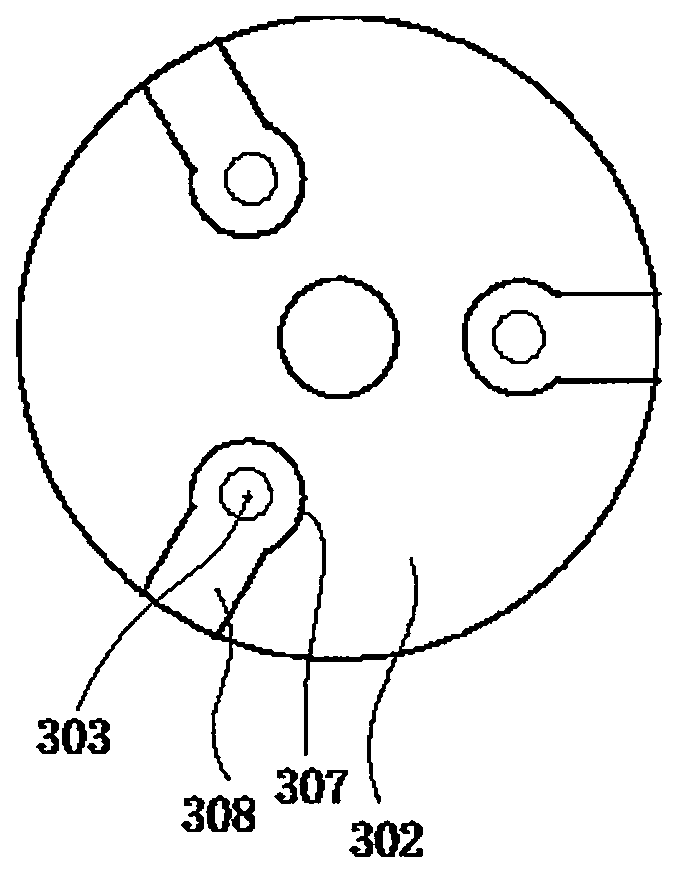

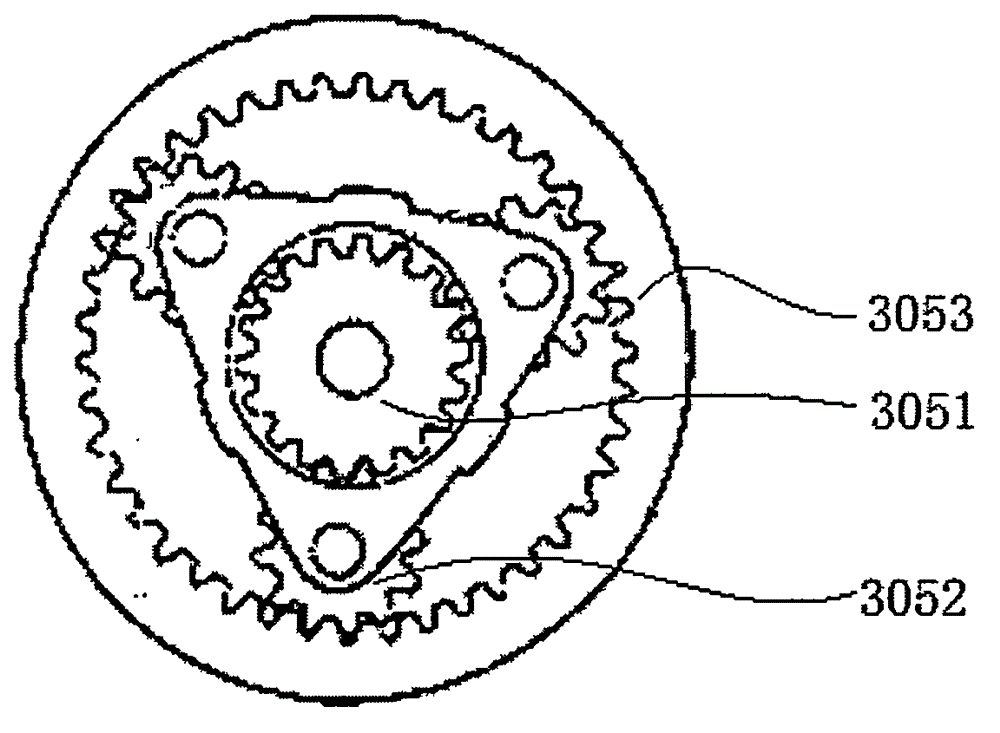

[0037] The complete set of equipment for forming, coating, folding, flattening and arranging of automatic lumpy viscous materials is composed of two conveyors installed on the frame with adjusting screw, which are respectively located at the upper and lower sides, with a certain distance, and with a conveying surface at an angle of 3-35 degrees. A flexible flattened belt conveyor consisting of several belt conveyor belts, a square frame support with multiple parallel beams on the top, and a motor-driven multi Rollers with ring grooves or rollers, square frame support frame or square frame support frame with pillars, and parallel beams installed on square frame support in pairs The rollers with multi-circle grooves or rollers, motors, and tension sleeves that are supported by a square frame-shaped support frame or a square frame-shaped support frame with pillars at an angle of 1-85° to the beam are wound on the belt. A flexible folding machine consisting of two interconnected r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com