Automatic production line for fresh food material pretreatment

An automatic production line and pretreatment technology, applied in the field of machinery and equipment, can solve the problems of inability to remove vegetable impurities, high labor intensity, and food safety, and achieve the effect of large market promotion value, reduced manual operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be further described in detail below in conjunction with specific embodiments.

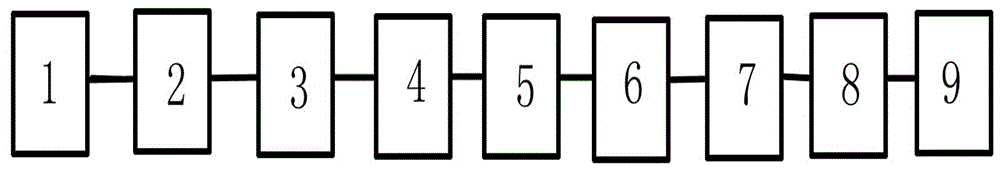

[0019] Such as figure 1 As shown, an automatic production line for pretreatment of fresh food materials consists of a six-station selection conveying platform 1, a vegetable cutter 2, a hoist 3, a pulse cleaning machine 4, a vibration draining machine 5, a secondary pulse cleaning machine 6, and a secondary The vibrating drainer 7, the station rotary receiving car 8 and the drying machine 9 are composed of a six-station selection conveying platform 1 and the vegetable cutter 2 connected by a conveyor belt, and the vegetable cutter 2 is connected with the hoist 3 at one end, and the lifting The other end of the machine 3 is connected to the pulse cleaning machine 4, the pulse cleaning machine 4 is connected to the vibration draining machine 5, the vibration draining machine 5 is connected to the secondary pulse cleaning machine 6, and the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com