An electric wheel hub automatic welding device

An automatic welding and electric vehicle technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as low production efficiency, restricting enterprise development, and expensive maintenance costs, improving product quality and production efficiency, and reducing labor intensity. , the effect of improving the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

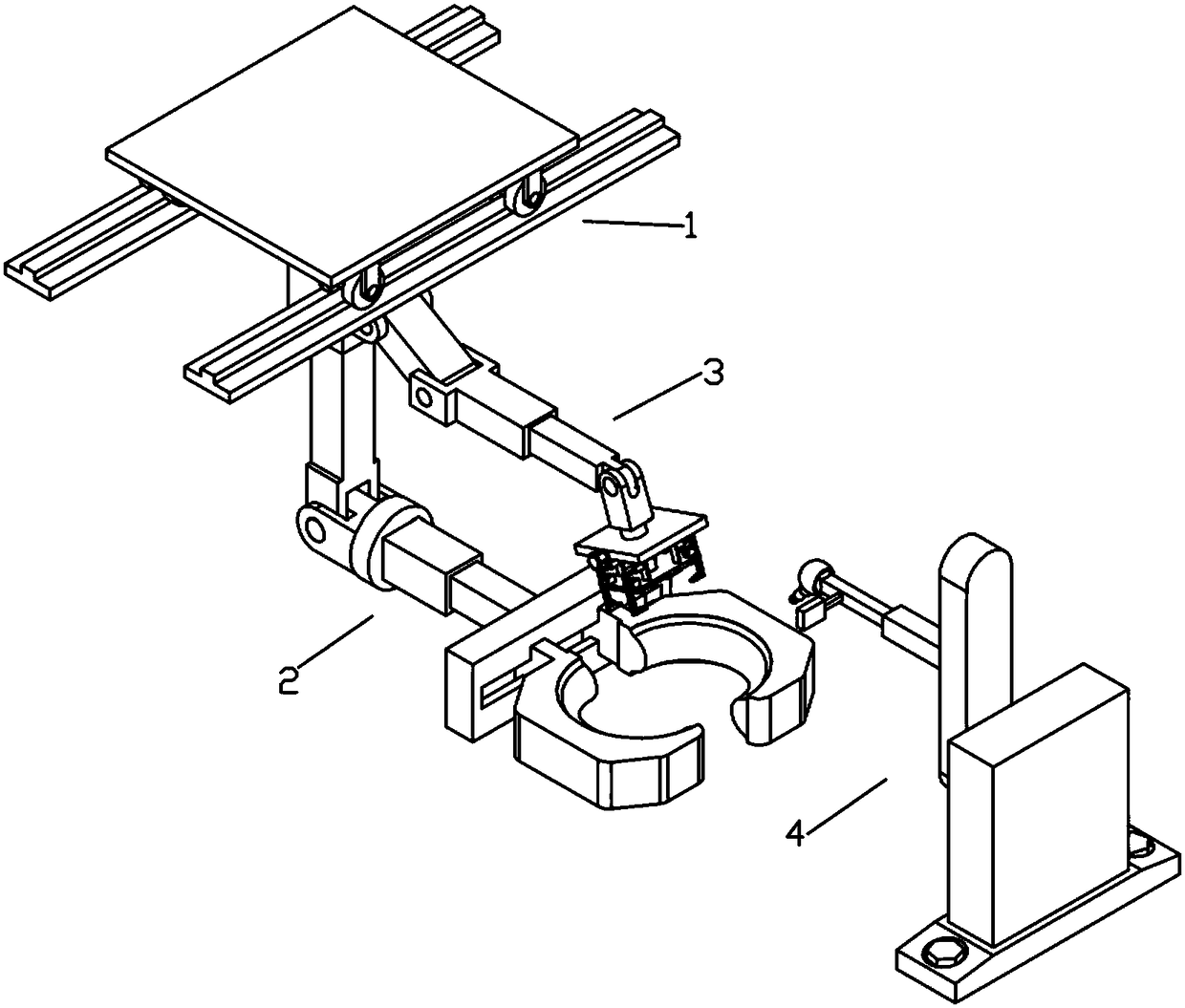

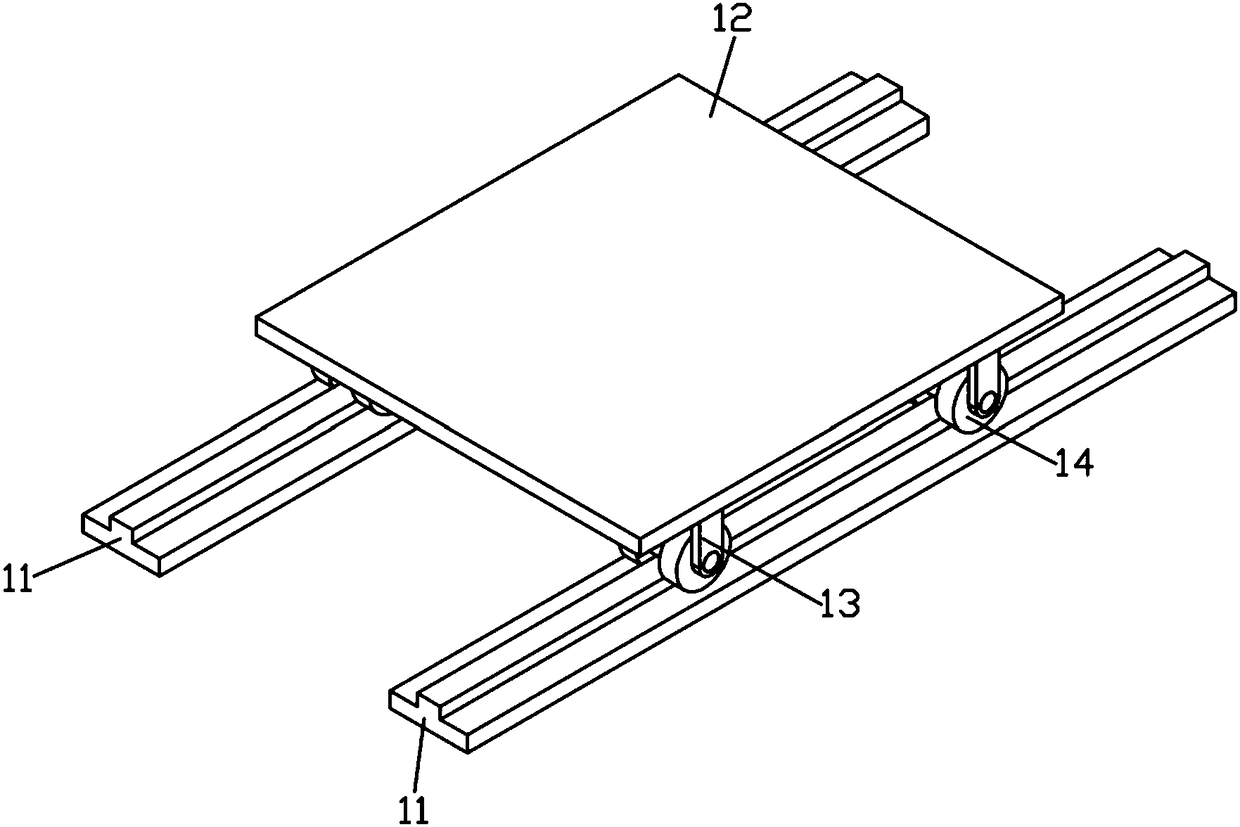

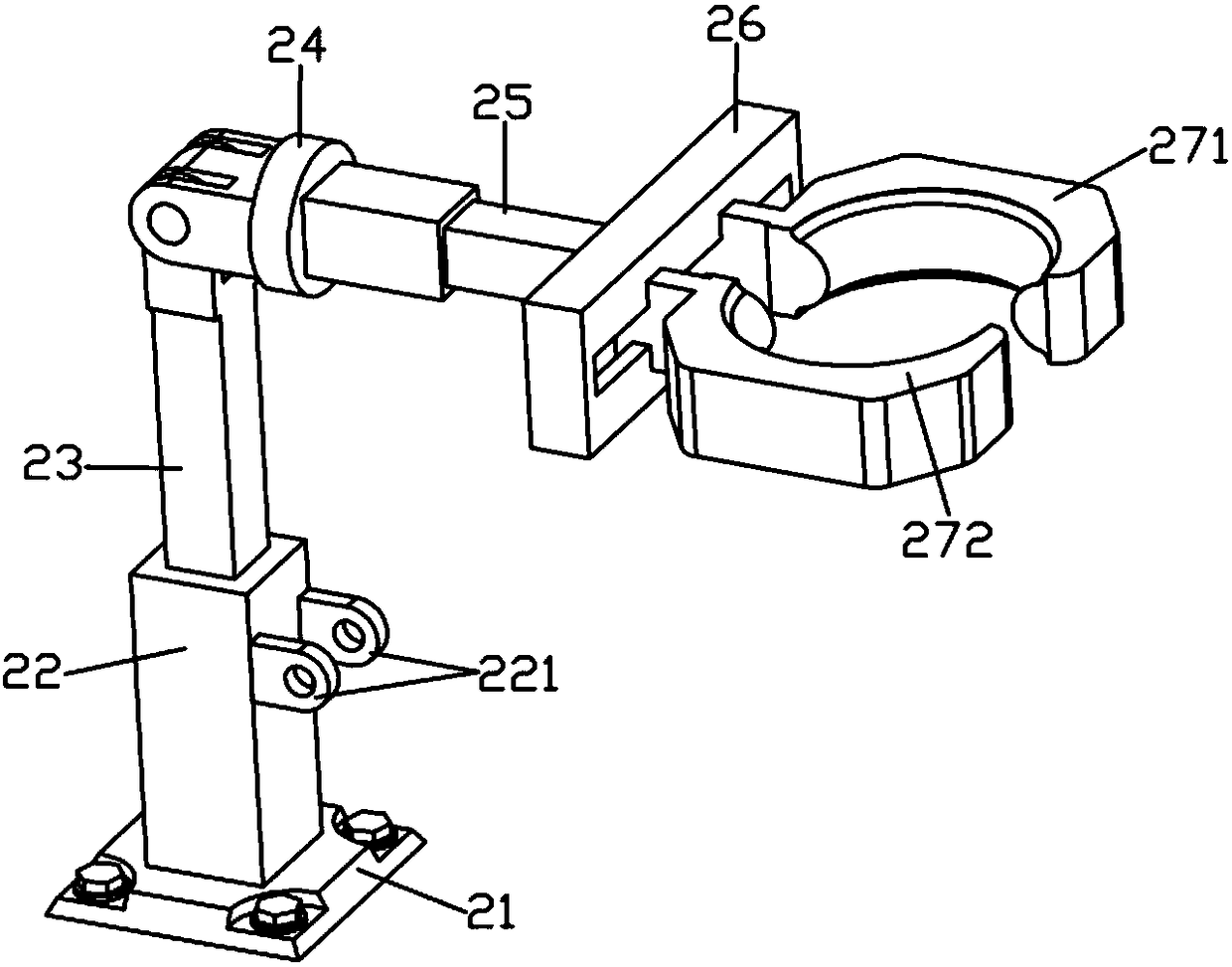

[0020] Such as figure 1 , 3 As shown, the electric wheel hub automatic welding device includes a sliding trolley 1, a welding jig 2, an adjustment component 3, a welding machine 4 and a control unit, the welding jig 2 is located directly below the sliding trolley 1, and the adjustment component 3 is hinged on the side of the welding jig 2 , the sliding trolley 1, the welding fixture 2, the adjustment part 3, and the welding machine 4 are all electrically connected to the control unit, the control unit includes a PLC microprocessor and the control system software part, and the control system software part includes the development of I / O human-computer interaction program Compiled with the welding master control program, the operation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com