Wrapped type pipe manufacturing mold core assembly

A core component and wrapping technology, which is applied in the field of wrapping tube-making core components, can solve the problems of low production efficiency and difficult to unify quality standards, and achieve the effect of high molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

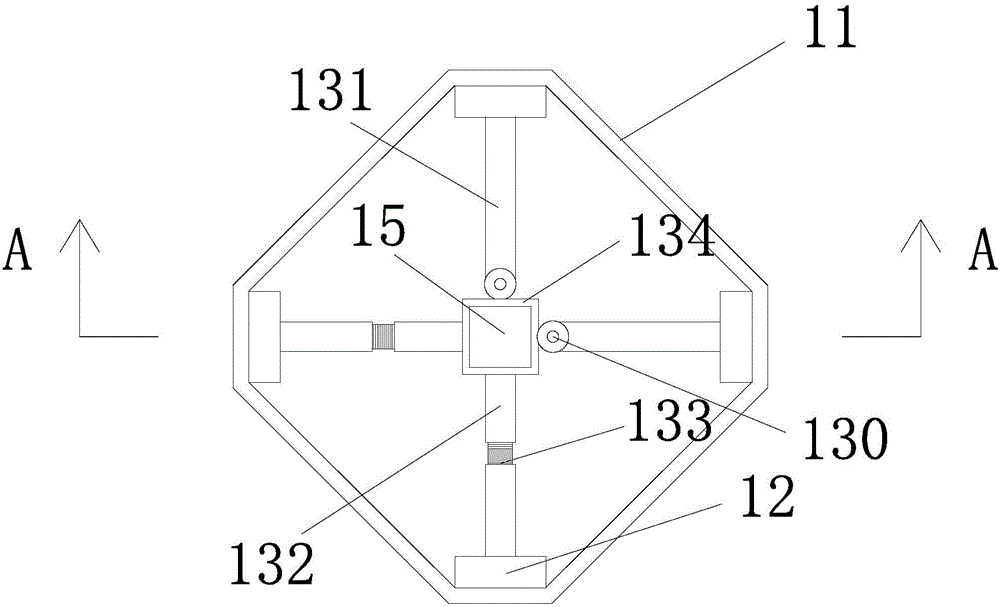

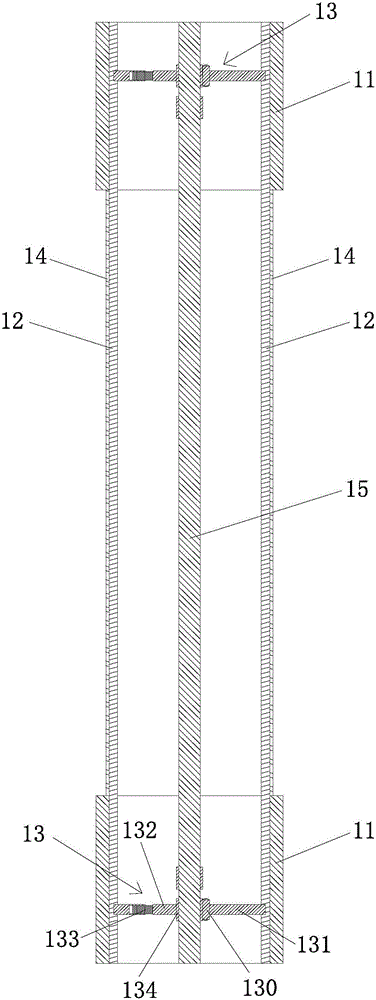

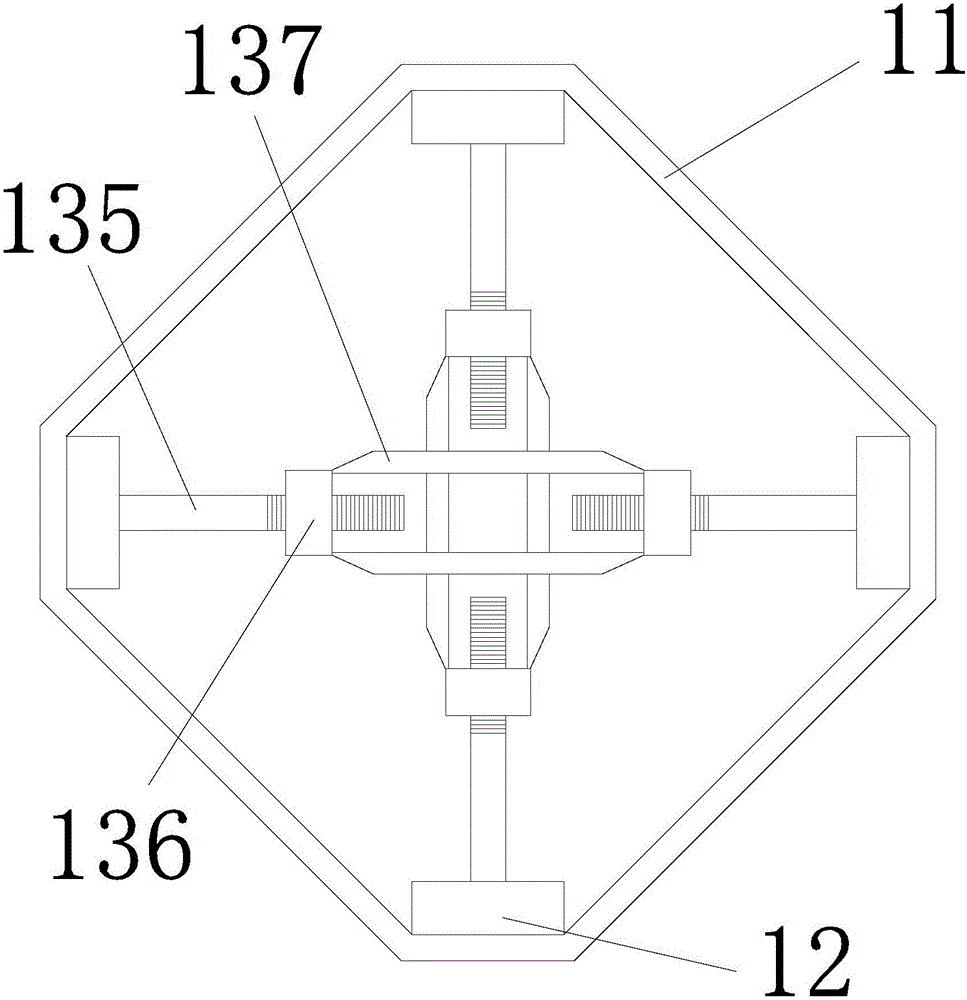

[0019] Such as Figure 1 to Figure 10 Shown is a schematic diagram of an embodiment of a wrap-type pipe-making core assembly provided by the present invention.

[0020] A packaged pipe-making mold core assembly, which includes two coaxial end dies 11 arranged at intervals, two or more vertical rods 12 inserted inside the end dies 11 and parallel to the central axis of the end dies 11, More than one telescopic mechanism 13 for expanding each upright bar 12 to the outside centering on the central axis of the end mold 11 and wrapping layer 14 wound around the outer circumference of the upright bar 12 between the end molds 11 and forming a continuous tubular structure , the number and shape of the vertical rods 12 are matched according to the cross-sectional shape of the inner cavity of the pipe.

[0021] If the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com