Creel

A yarn creel and yarn bobbin technology is applied in the field of webbing manufacturing, which can solve the problems of time-consuming, yarn winding and knotting, and increase the chance of error, and achieve the effect of saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

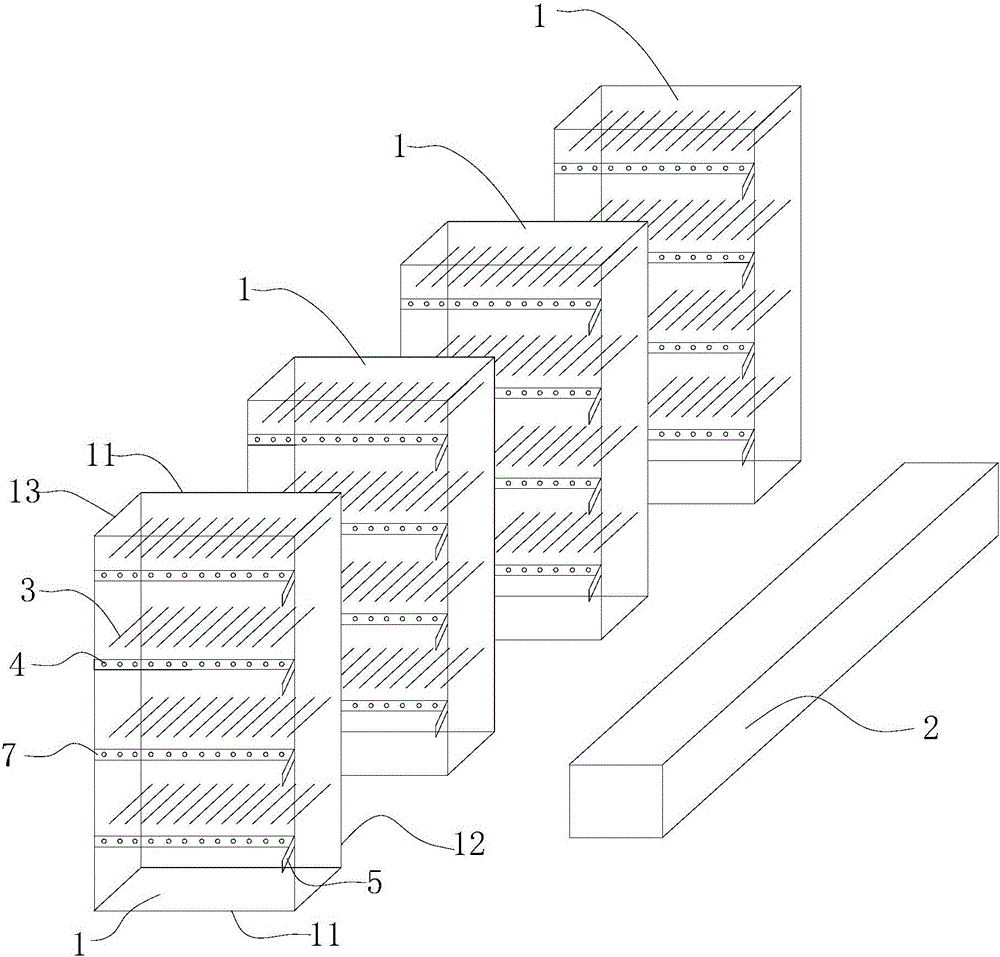

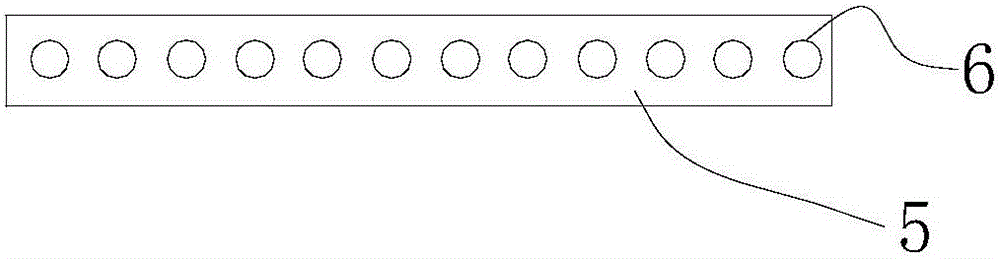

[0022] Combine below figure 1 , figure 2 The technical solutions of the present invention are further described through specific implementation methods.

[0023] It should be noted that the "front", "back", "up", and "down" mentioned in the present invention are relative to the direction of the page view, that is, the direction close to the reader is the front, and the direction away from the reader is the front. The side opposite to the front side is the rear, the direction of the upward line of sight is upward, and the direction of the downward line of sight is downward, which should not be construed as limiting the protection scope of the present invention.

[0024] like figure 1 , figure 2 As shown, a creel of the present invention includes several warp yarn creels 1 arranged side by side. All warp thread creels 1 are arranged on the same side of the textile machine 2 and are vertically placed relative to the textile machine 2. The warp thread creel 1 includes The cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com