Water permeable concrete

A technology of concrete and water permeability, which is applied in the field of concrete for construction. It can solve the problems of unsatisfactory concrete water permeability and compressive strength, the inability to apply large-scale infrastructure, and the high cost of concrete pavement, so as to prevent slipping and excellent compressive strength. , the effect of reducing the temperature of the road surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

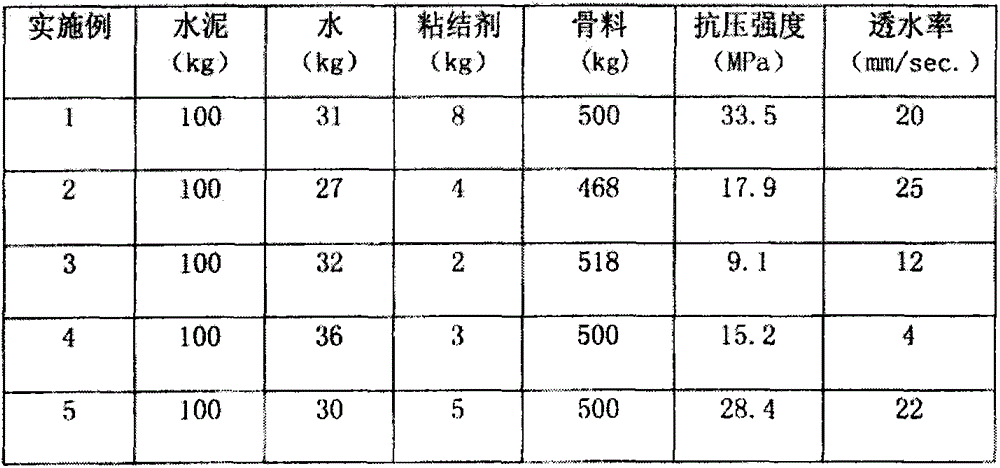

Embodiment 1

[0017] The measurement method of water permeability is as follows: 100 kg of cement (PO 42.5 type), 31 kg of water, 8 kg of binder (styrene-butadiene copolymer binder, SN623 type), 500 kg of particle size Concrete was prepared by mixing aggregates of 5-35mm, and after natural curing for 28 hours, its water permeability and compressive strength were measured. Among them, the measurement of the compression method can be carried out according to GB / T5003-2002 or JTJ053-94 experiment. The water permeability measurement method is as follows:

[0018] Preparation of concrete specimens with vertical perimeter walls for measurement;

[0019] Lay the test piece flat, and then put the bottomless glass cylinder on it, aligning all sides.

[0020] Wrap the test piece and the lower part of the bottomless glass cylinder tightly with plastic paper, and then wrap it tightly from the outside with wide-band glue; there must be no wrapping or blocking at the top and bottom of the test piece, a...

Embodiment 2

[0033] 100 kilograms of cement (PO 42.5 type), 27 kilograms of water, 4 kilograms of binding agent (SN623 type), 468 kilograms of aggregates with a particle size of 8-35mm are mixed to prepare concrete, after 28 days of natural curing, adopt embodiment 1 Its water permeability and compressive strength were measured by the method in . The results are shown in Table 1 below.

Embodiment 3

[0035] 100 kilograms of cement (PO 42.5 type), 32 kilograms of water, 2 kilograms of binding agent (SN623 type), 518 kilograms of aggregates with a particle size of 8-35mm are mixed to prepare concrete, and after 28 days of natural curing, adopt embodiment 1 Its water permeability and compressive strength were measured by the method in . The results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com