A method for preparing ultra-high α-phase silicon nitride by using silicon nanotubes

A technology of phase silicon nitride and silicon nanotubes, which is applied in the field of preparing ultra-high alpha phase silicon nitride by using silicon nanotubes, can solve the problems of difficulty in controlling the degree of nitridation, unsuitable for industrial production, complicated operation process, etc. The effect of increasing the reaction rate, suppressing self-sintering, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

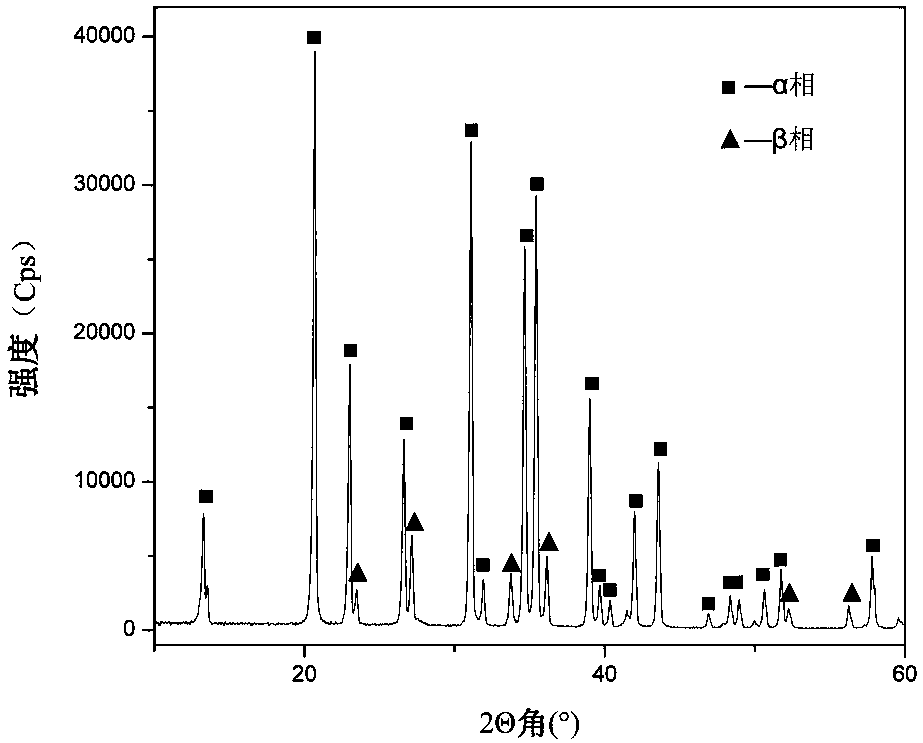

[0023] Silicon nanotubes are used as raw materials, the outer diameter is 400nm, the inner diameter is 250nm, and the specific surface area is 24m2 / g. Under a nitrogen atmosphere, keep warm at 1350°C for 25 hours to obtain loose high-α-phase silicon nitride; then use a planetary ball mill to perform planetary high-energy ball milling on the obtained silicon nitride. The ball milling speed is 1000r / min, and the milling time is 30h, and ultra-high α-phase silicon nitride with uniform particle size distribution can be obtained.

[0024] The product prepared in this embodiment is carried out X-ray energy spectrum analysis (XRD), the result is as follows figure 1 As shown, the α-phase content is 94.8%.

Embodiment 2

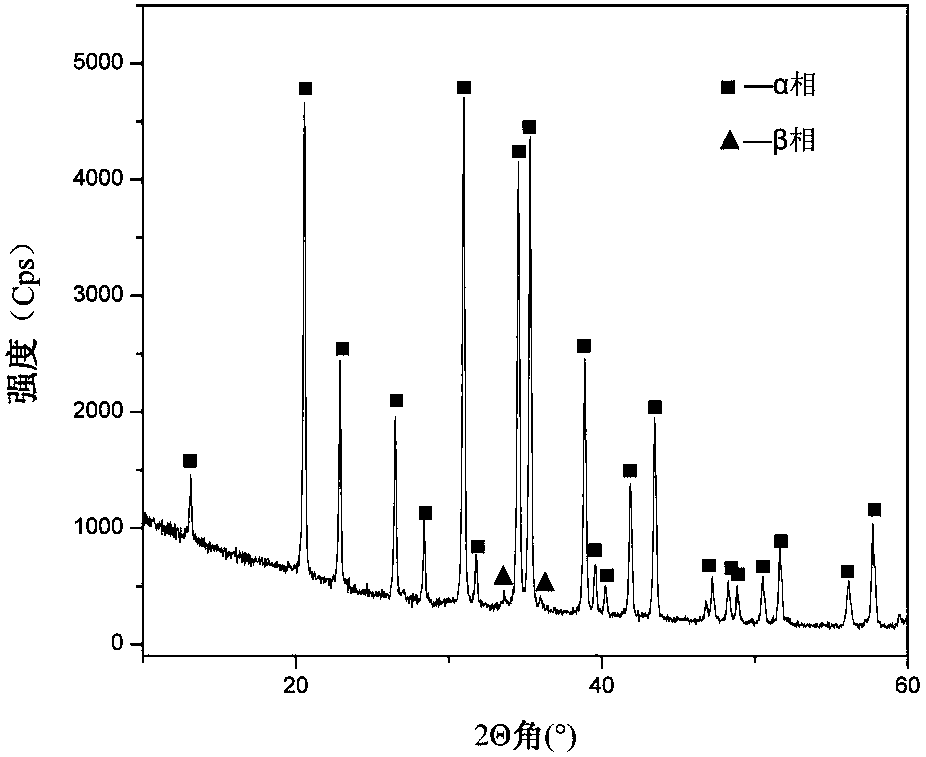

[0026] Silicon nanotubes are used as raw materials, the outer diameter is 150nm, the inner diameter is 85nm, and the specific surface area is 75m2 / g. Under a nitrogen atmosphere, keep warm at 1300°C for 22 hours to obtain loose high-α-phase silicon nitride; then use a planetary ball mill to perform planetary high-energy ball milling on the obtained silicon nitride. The ball milling speed is 1000r / min, and the time is 26h, and ultra-high α-phase silicon nitride with uniform particle size distribution can be obtained.

[0027] The product prepared in this embodiment is carried out X-ray energy spectrum analysis (XRD), the result is as follows figure 2 As shown, the α-phase content is 97.9%.

Embodiment 3

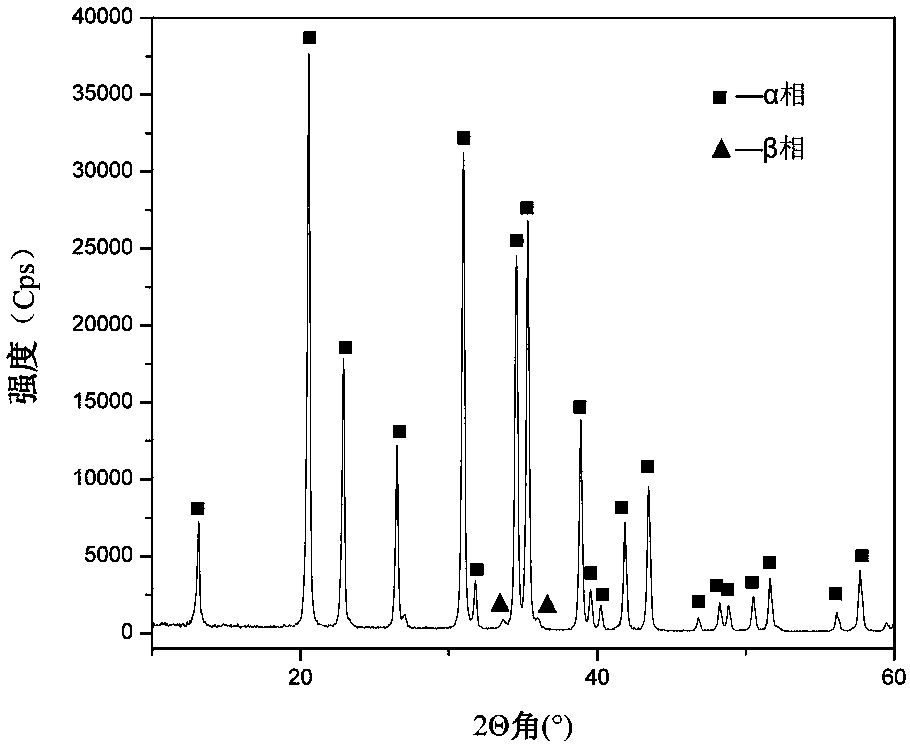

[0029] Silicon nanotubes are used as raw materials, with an outer diameter of 75nm, an inner diameter of 30nm, and a specific surface area of 90m2 / g. In a nitrogen atmosphere, keep warm at 1250°C for 20 hours to obtain loose high-α-phase silicon nitride; then use a planetary ball mill to perform planetary high-energy ball milling on the obtained silicon nitride. The ball milling speed is 1000r / min, and the time is 22h, and ultra-high α-phase silicon nitride with uniform particle size distribution can be obtained.

[0030] The product prepared in this embodiment is carried out X-ray energy spectrum analysis (XRD), the result is as follows image 3 As shown, the α-phase content is 99.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com