A kind of modified asphalt for waterproof membrane and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of unqualified low-temperature flexibility of the membrane, yellowing of the surface of the membrane, and shortened product life, achieving significant economic benefits. Benefits and social benefits, slow decay, guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of the modified bitumen that is used for waterproof membrane

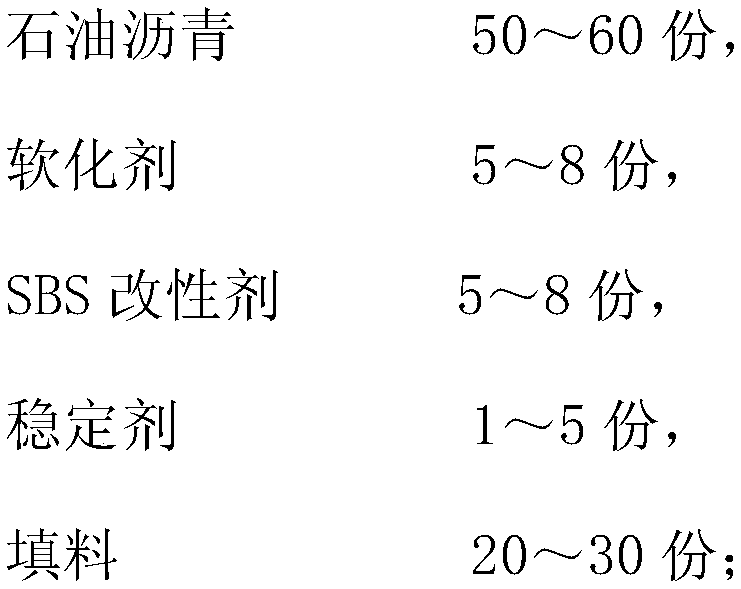

[0028] 1. Composition of modified bitumen for waterproofing membrane

[0029]

[0030] 2. Preparation of modified asphalt for waterproof membrane

[0031] Stir 55wt parts of Qinhuangdao 90# asphalt and 8wt parts of pentaerythritol oleate and heat up to 160-170°C, then add 7wt parts of Yanshan Petrochemical SBS1401, 5wt parts of Qingyun Dexin polypropylene stabilizer, and heat at 1000-2000rpm / min Mix for 2 to 3 hours at a rotating speed, then add 25 wt parts of talcum powder, stir for 1 hour, and then place it in a storage tank.

[0032] 3. Performance of waterproof membrane products

[0033] The modified bitumen prepared in Example 1 was used to prepare the waterproof membrane, and the comparison results of product testing performance are shown in Table 1.

[0034] Table 1 - Comparison results of testing performance of modified bitumen waterproofing membrane products

[0...

Embodiment 2

[0037] Embodiment 2: the preparation of the modified bitumen that is used for waterproof membrane

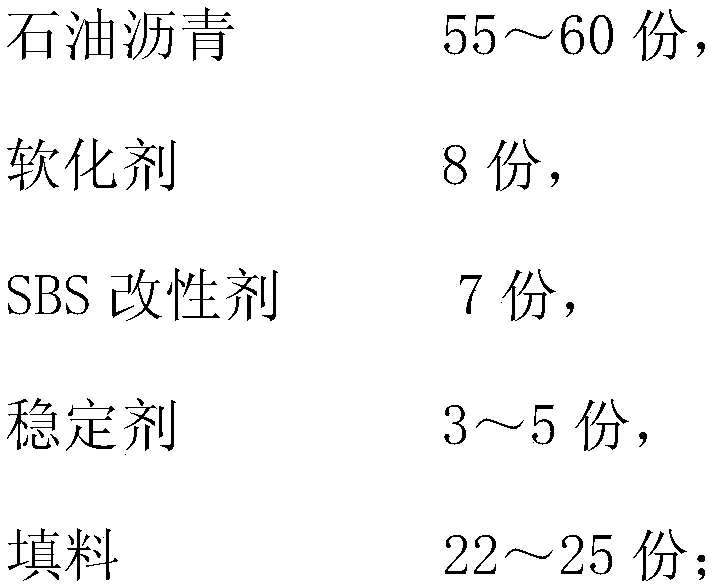

[0038] 1. Composition of modified bitumen for waterproofing membrane

[0039]

[0040] 2. Preparation of modified asphalt for waterproof membrane

[0041] Stir 56wt parts of Qinhuangdao 90# asphalt and 7wt parts of polyethylene glycol to heat up to 160-170°C, then add 6wt% of Yanshan Petrochemical SBS1401, 6wt parts of Qingyun Dexin polypropylene stabilizer, and set the temperature at 1000-2000rpm / min Mix for 2 to 3 hours at a rotating speed, then add 25 wt parts of talcum powder, stir for 1 hour, and then place it in a storage tank.

[0042] 3. Performance of waterproof membrane products

[0043] The modified asphalt prepared in Example 2 was used to prepare the waterproof membrane, and the comparison results of product testing performance are shown in Table 2.

[0044] Table 2 - Comparison results of testing performance of modified bitumen waterproofing membrane products...

Embodiment 3

[0047] Embodiment 3: the preparation of the modified bitumen that is used for waterproof membrane

[0048] 1. Composition of modified bitumen for waterproofing membrane

[0049]

[0050] 2. Preparation of modified asphalt for waterproof membrane

[0051] Stir 55wt parts of Qinhuangdao 90# asphalt and 6wt parts of glycerin to 160-170°C, then add 8wt parts of Yanshan Petrochemical SBS1401, 4wt parts of Qingyun Dexin polypropylene stabilizer, and rotate at 1000-2000rpm / min Mix for 2-3 hours, then add 27 wt parts of talcum powder, stir for 1 hour, and then place it in a storage tank.

[0052] 3. Performance of waterproof membrane products

[0053] The modified asphalt prepared in Example 3 was used to prepare the waterproof membrane, and the comparison results of product testing performance are shown in Table 3.

[0054] Table 3 - Comparison results of testing performance of modified bitumen waterproofing membrane products

[0055]

[0056] Remarks: Petroleum hydrocarbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com