Pyrolysis equipment and method with automatic feeding, loading and unloading functions

An automatic feeding and charging technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of low degree of automation, achieve high degree of automation, save energy, and reduce heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

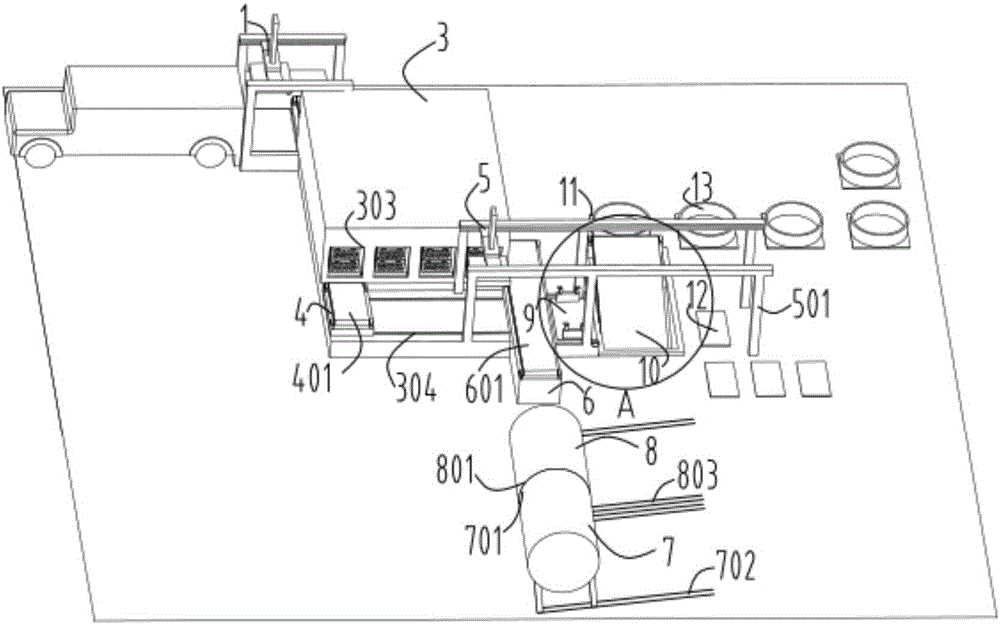

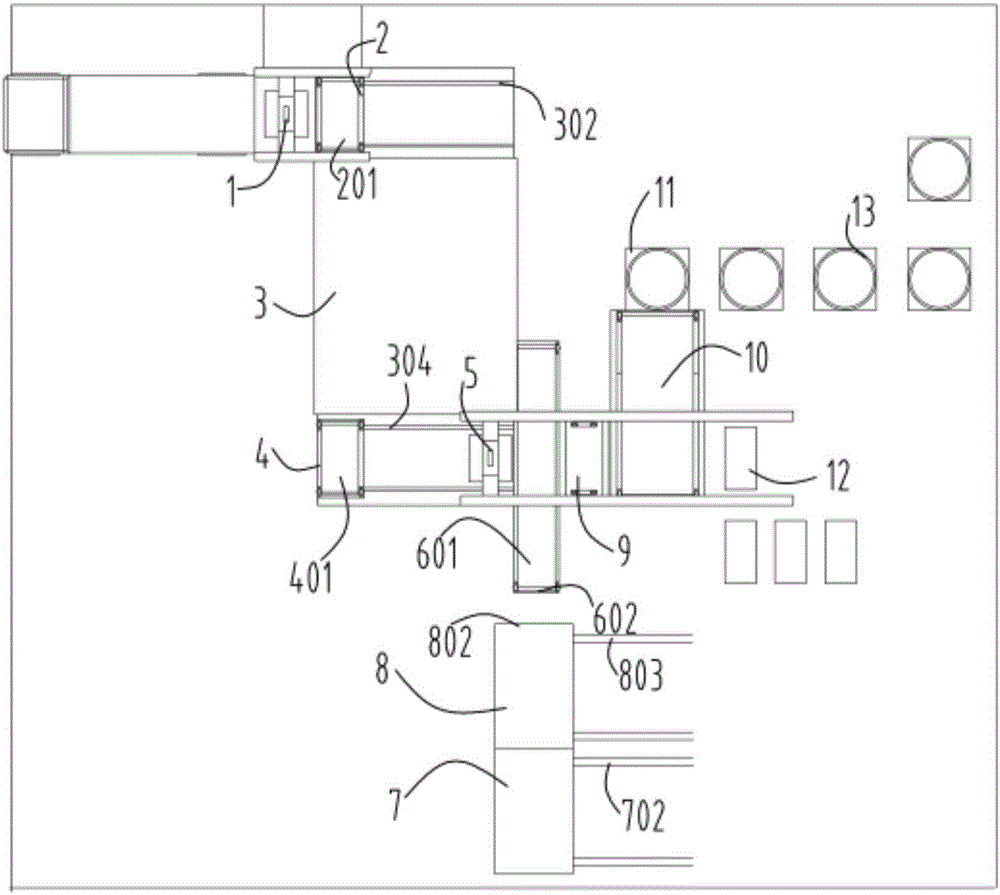

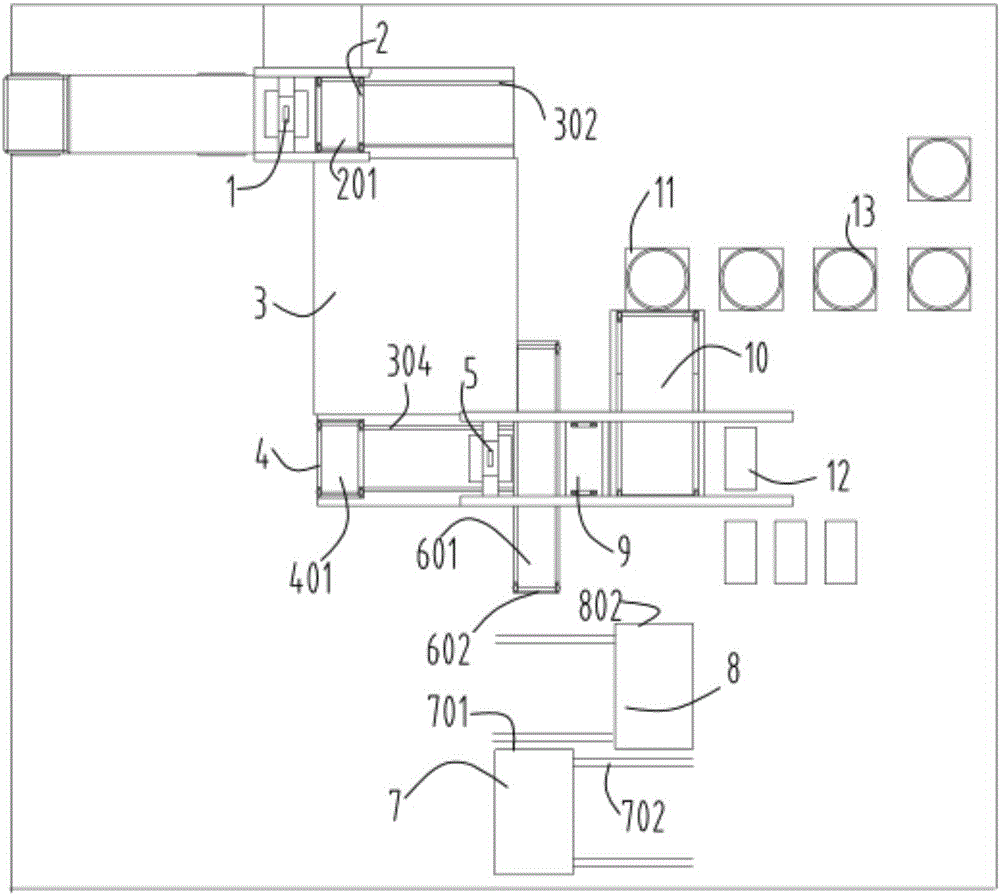

[0043] figure 1 It is an isometric schematic diagram of pyrolysis equipment with automatic loading, loading and unloading functions, figure 2 It is a top view diagram of pyrolysis equipment with automatic feeding, loading and unloading functions, image 3 It is a top view schematic diagram of another working state of the pyrolysis equipment with automatic loading, loading and unloading functions, Figure 4 Magnified isometric perspective illustration for cold storage, Figure 5 Zoom in on the perspective schematic diagram of the cold storage, Figure 6 for figure 1 Partial enlarged schematic diagram of middle A. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, what is provided in this embodiment is a pyrolysis device and method with automatic feeding, loading and unloading functions.

[0044] A pyrolysis equipment with automatic loading, loading and unloading functions, including a movable conveying platform A2, a turnover dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com