Total-synthesis hydraulic oil with super-long oil change period

An oil change interval, hydraulic oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of general oil efficacy, decline in oil quality, complex production process, etc., and achieve excellent shear resistance and low pour point. , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

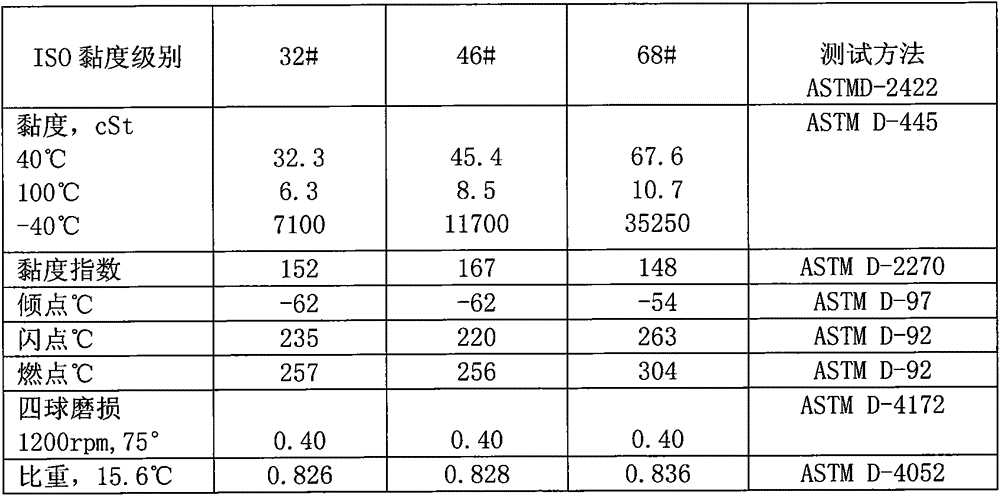

Embodiment 1

[0021] A fully synthetic ultra-long oil change interval hydraulic oil, composed of synthetic base oil, antioxidant, detergent, dispersant, rust inhibitor, antifoaming agent, metal deactivator, demulsifier, antiwear agent, antipolar The base oil is composed of pressure agent, viscosity index improver and pour point depressant. The base oil is a mixture of two components, PAO150 and PAO6. The weight ratio of the two components is 3:1. Antioxidant is 2.6-di-tert-butyl mixed phenol, detergent is calcium alkyl salicylate, dispersant is monoalkenyl succinimide, rust inhibitor is alkyl succinic acid derivative, antifoaming agent is Polydimethylsiloxane, metal deactivator is 2-mercaptobenzothiazole, demulsifier is polyalkoxy polyol, antiwear agent is dithiophosphate, anti-extreme pressure agent is molybdenum disulfide, The viscosity index improver is styrene diene copolymer, and the pour point depressant is polymethacrylate. The weight share ratio of each component is: base oil 90.4%,...

Embodiment 2

[0030] A fully synthetic ultra-long oil change interval hydraulic oil, composed of base oil, antioxidant, detergent, dispersant, rust inhibitor, anti-foaming agent, metal deactivator, demulsifier, anti-wear agent, anti-extreme pressure The base oil is composed of PAO 150 and PAO 6, 250N III, and the weight ratio of the three components is 1:1:1. Antioxidant is 2.6-di-tert-butyl mixed phenol, detergent is calcium alkyl salicylate, dispersant is monoalkenyl succinimide, rust inhibitor is alkyl succinic acid derivative, antifoaming agent is Polydimethylsiloxane, metal deactivator is 2-mercaptobenzothiazole, demulsifier is polyalkoxy polyol, antiwear agent is dithiophosphate, anti-extreme pressure agent is molybdenum disulfide, The viscosity index improver is styrene diene copolymer, and the pour point depressant is polymethacrylate. The weight share ratio of each component is: base oil 89.2%, antioxidant 1%, detergent 2%, dispersant 0.7% , rust inhibitor 0.5%, antifoaming agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com