A universal proofer for supercritical fluid anhydrous dyeing

A supercritical fluid, anhydrous dyeing technology, applied in the treatment of textile material dyeing devices, textile processing machine accessories, textile material processing, etc. The needs of small sample proofing, the low utilization rate of equipment and systems, etc., can promote the generation and discharge of pollutants, overcome the low proofing efficiency, and improve the repeatability and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

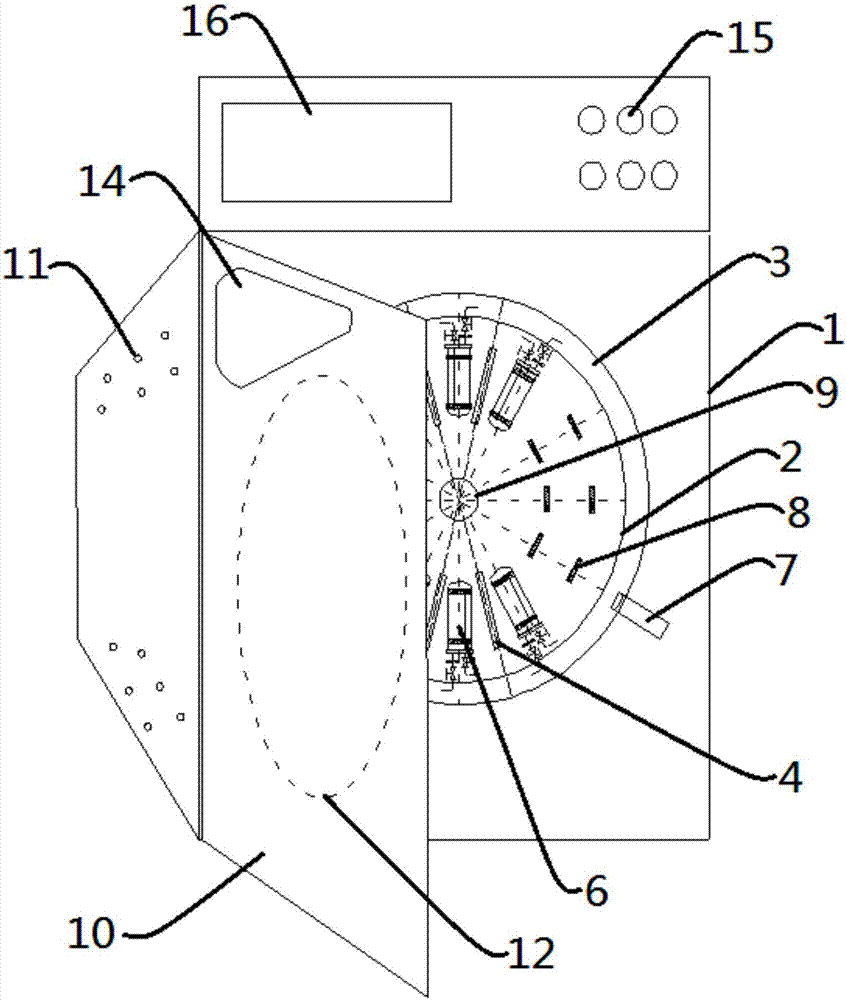

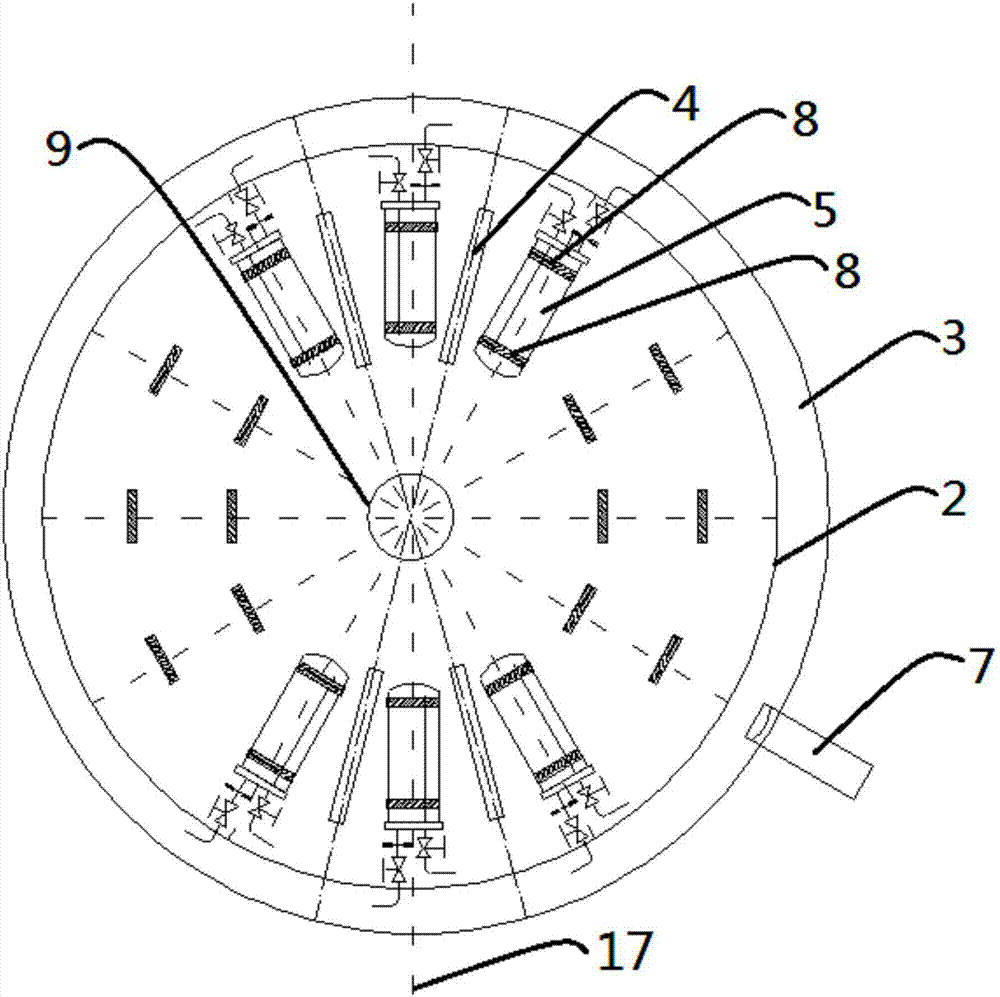

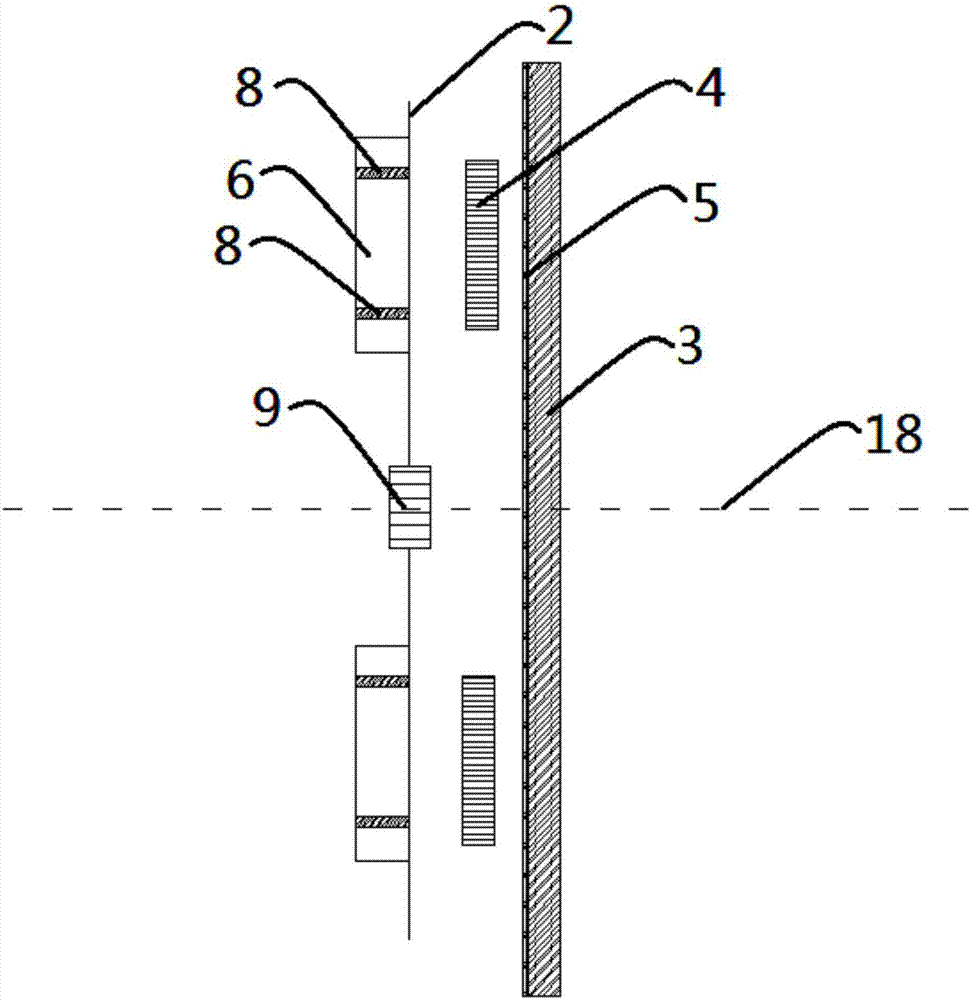

[0032] Example: refer to Figures 1 to 6 As shown, a universal proofer for supercritical fluid anhydrous dyeing includes a proofer case 1, a rotating frame 2 arranged vertically inside the proofer case 1, and a front and back coaxial center, an adiabatic disc 3, and a rotating The rotating drive shaft 9 fixedly connected to the frame 2 is coaxial; between the rotating frame 2 and the heat-insulating disk 3, on the circumferential surface coaxial with the rotating frame 2 and the heat-insulating disk 3, several infrared rays arranged radially are arranged. The heating tube 4 is covered with an infrared reflective film or a coating 5 on the outer surface of the heat insulating plate 3 near the side of the infrared heating tube 4; on the rotating frame 2, several dyeing cups 6 arranged radially are arranged, and the dyeing cups 6 is a supercritical fluid anhydrous dyeing and proofing cup, and its main body shape and the connection mode and position of accessories such as high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com