Preparation method of Al-doped zinc oxide transparent conductive thin film

A technology of transparent conductive film and inductive coupling, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem of not achieving large-area uniform coating, high temperature of film deposition substrate, and expensive organic zinc source and other issues, to achieve the effect of low cost, dense crystal and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

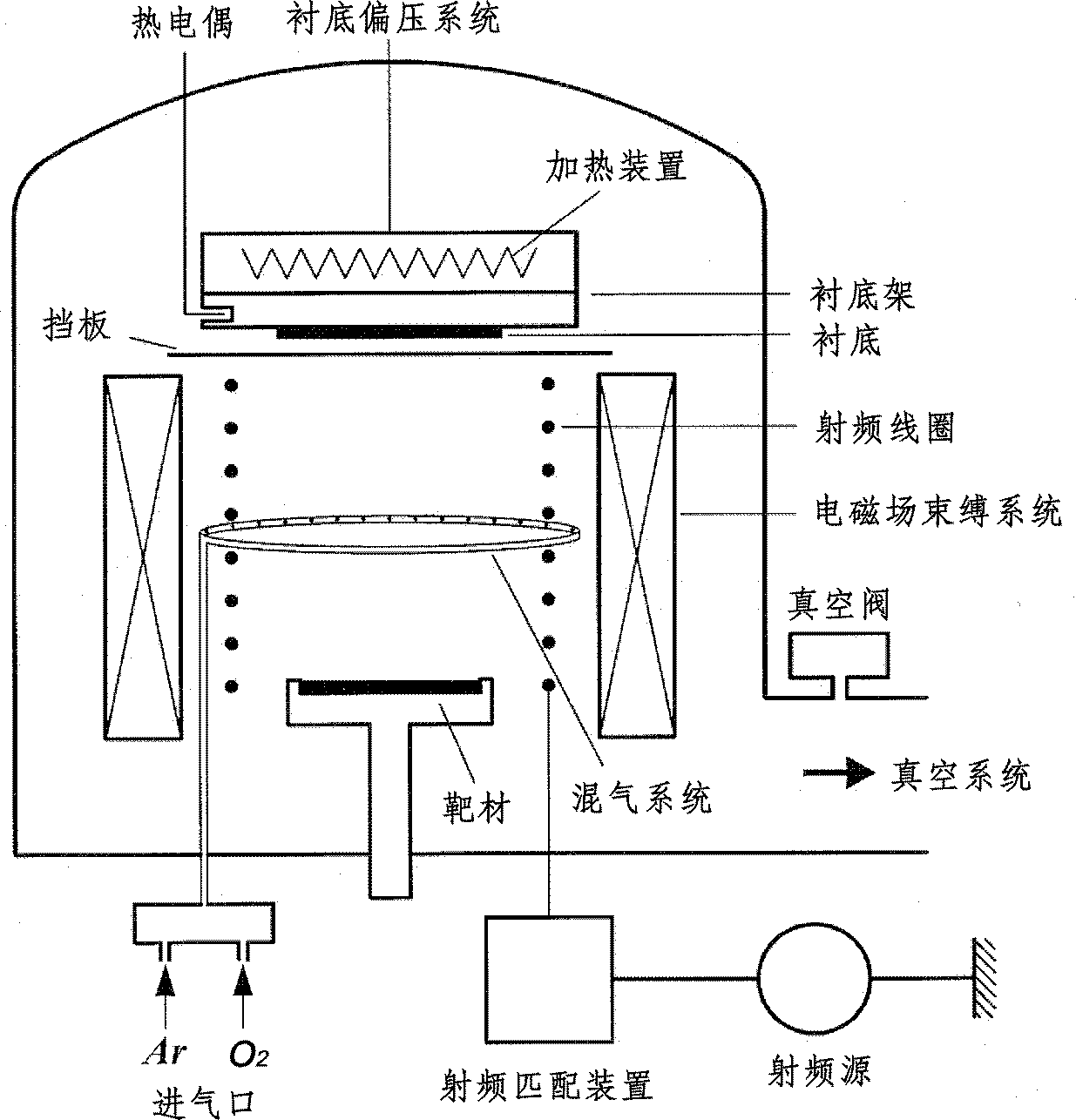

Method used

Image

Examples

Embodiment 1

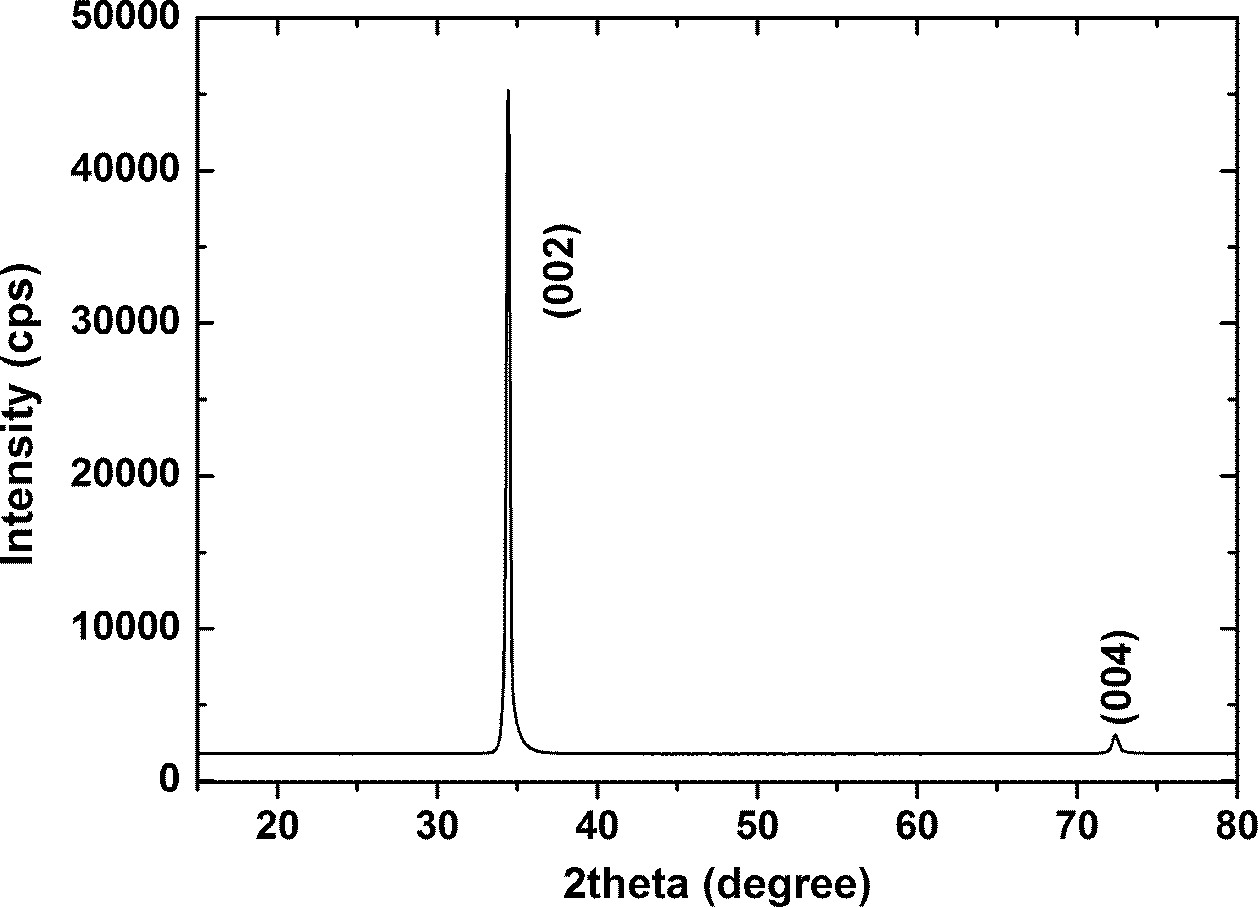

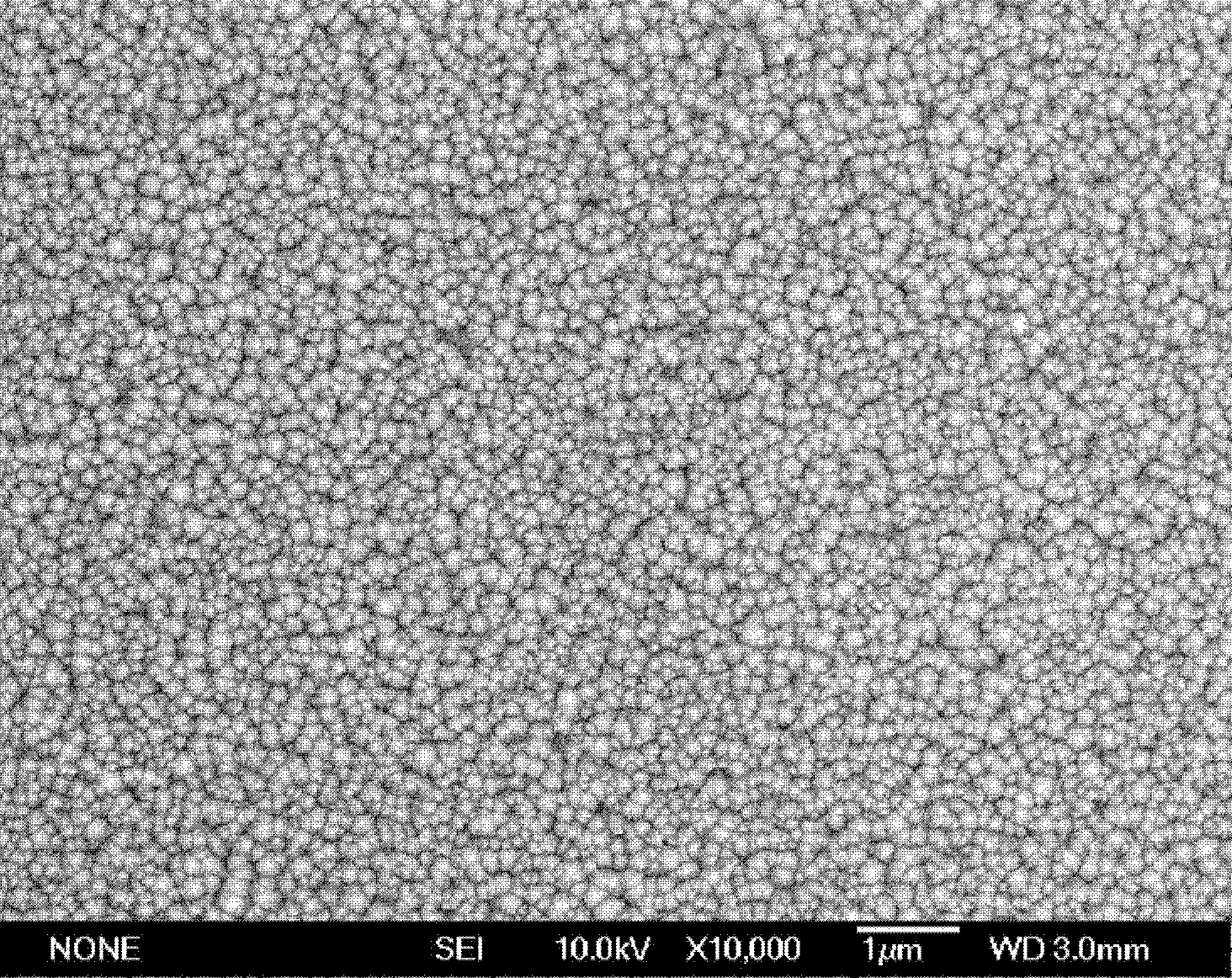

[0035] Doped ZnO thin film Zn with 2 mol% Al 0.98 Al 0.02 O as an example:

[0036] (1) Zn was prepared by a standard isostatic solid-state reaction synthesis process 0.98 Al 0.02 O target. Press Zn with electronic balance 0.98 Al 0.02 The stoichiometric ratio of the corresponding elements of O Weigh high-purity (≥99.99%) ZnO (40.695g) and Al 2 o 3 (0.520g), after being fully mixed, pre-pressed (50MPa), then cold isostatic pressed (200MPa), and finally placed in a tubular electric furnace and gradually heated to 1000 ° C, and kept for 48 hours.

[0037] (2) The quartz glass substrate is cleaned with N 2 Blow dry and place in the ICP-PVD reaction chamber.

[0038] (3) Pump the background vacuum of the ICP-PVD system to 1×10 -7 Torr, and then heat the substrate, the substrate temperature is 400°C.

[0039] (4) Using high-purity (≥99.9995%) Ar as the carrier gas and plasma source, the reaction chamber pressure is 100 Torr, the RF sputtering power is 150W, the binding c...

Embodiment 2

[0048] ZnO thin film doped with 1% Al by mole Zn 0.99 Al 0.01 O as an example:

[0049] (1) Zn was prepared by a standard isostatic solid-state reaction synthesis process 0.99 Al 0.01 O target. Press Zn with electronic balance 0.99 Al 0.01 The stoichiometric ratio of the corresponding elements of O Weigh high-purity (≥99.99%) ZnO (40.695g) and Al 2 o 3 (0.257g), after being fully mixed, pre-pressed (50MPa), then cold isostatic pressed (200MPa), and finally placed in a tubular electric furnace and gradually heated to 1000 ° C, and kept for 48 hours.

[0050] (2) Clean the Si substrate with N 2 Blow dry and place in the ICP-PVD reaction chamber.

[0051] (3) Pump the background vacuum of the ICP-PVD system to 5×10 -8 Torr, and then heat the substrate, the substrate temperature is 300°C.

[0052] (4) Using high-purity (≥99.9995%) Ar as the carrier gas and plasma source, the reaction chamber pressure is 50Torr, the RF sputtering power is 200W, the binding coil current i...

Embodiment 3

[0057] Doped ZnO thin film Zn with 5 mol% Al 0.95 Al 0.05 O as an example:

[0058] (1) Zn was prepared by a standard isostatic solid-state reaction synthesis process 0.95 Al 0.05 O target. Press Zn with electronic balance 0.95 Al 0.05 The stoichiometric ratio of the corresponding elements of O Weigh high-purity (≥99.99%) ZnO (40.695g) and Al 2 o 3 (1.342g), after being fully mixed, pre-pressed (50MPa), then cold isostatic pressed (200MPa), and finally placed in a tubular electric furnace and gradually heated to 1000 ° C, and kept for 48 hours.

[0059] (2) Clean the Si substrate with N 2 Blow dry and place in the ICP-PVD reaction chamber.

[0060] (3) Pump the background vacuum of the ICP-PVD system to 5×10 -8 Torr, and then heat the substrate, the substrate temperature is 350°C.

[0061] (4) Use high-purity (≥99.9995%) Ar as the carrier gas and plasma source, the reaction chamber pressure is 50Torr, the RF sputtering power is 150W, the binding coil current is 0.4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com