Underground coal mine sleeve chambering and screen pipe lowering device and construction method

A technology of casing and screen pipe, which is applied in the direction of earthwork drilling, wellbore/well components, and production fluids, etc., which can solve the problem of not being able to effectively ensure the smooth flow of drainage channels for a long time, failing to fully play the role of drilling, and being unable to go down to Expected depth and other issues, to achieve the effect of small resistance, reduce the number of trips and save construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

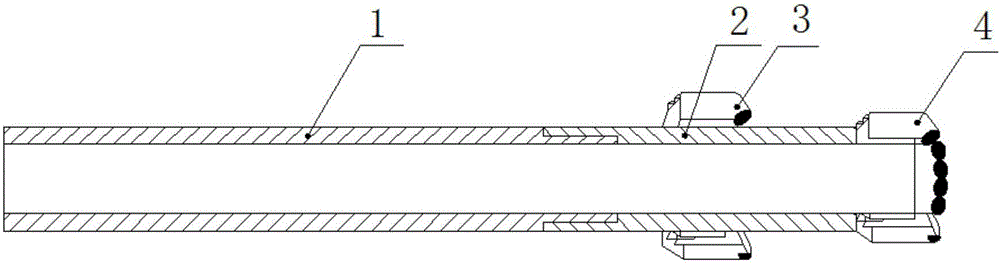

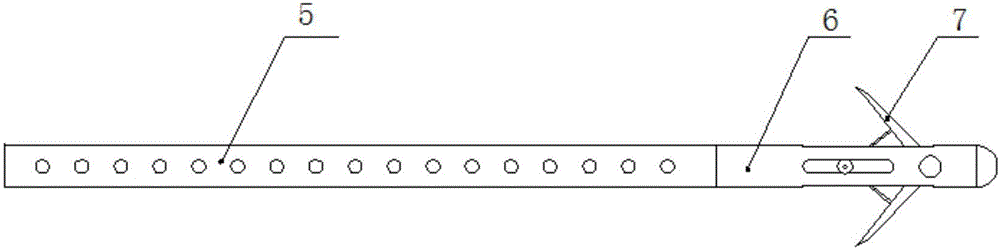

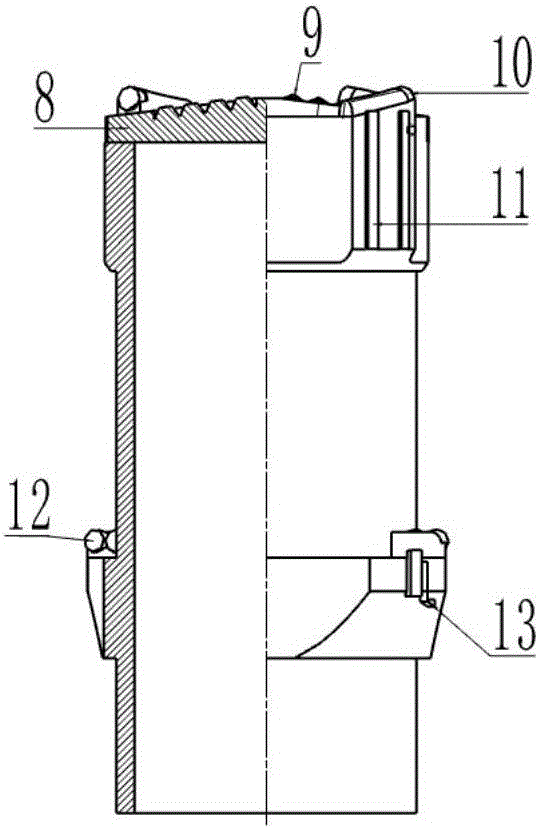

[0026] see figure 1 and 2 , shows the coal mine downhole casing reaming lower screen pipe device of the present invention.

[0027] The coal mine casing reaming lower screen pipe device and construction method include a casing pipe 1, an open and close reaming drill bit 2, a screen pipe 5 and a suspension device 6, and the casing pipe 1 has a thin wall and a large inner through hole diameter; The front end of the open-close reaming bit 2 is provided with an open-close structure 4, the outer edge of the middle part is provided with a reaming assembly 3, and the rear end includes a connecting structure; 6. A suspension device 6 is connected to the front end of the screen pipe 5 .

[0028] Thus, the casing 1 and the open-close reaming bit 2 are driven to perform rotary reaming drilling through the rotation of the orifice, and the screen pipe 5 and the suspension device 6 are lowered through the inside of the casing 1, and then the open-close drill bit 2 is pushed open. Stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com