Plate type pulsating heat pipe and manufacturing method thereof

A technology of pulsating heat pipes and manufacturing methods, which is applied in the direction of cooling/ventilation/heating transformation, indirect heat exchangers, lighting and heating equipment, etc., which can solve the problems of increasing the manufacturing cost of vapor chambers, the inability of working fluid to flow, and the capillary structure layer being easy to fall off And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

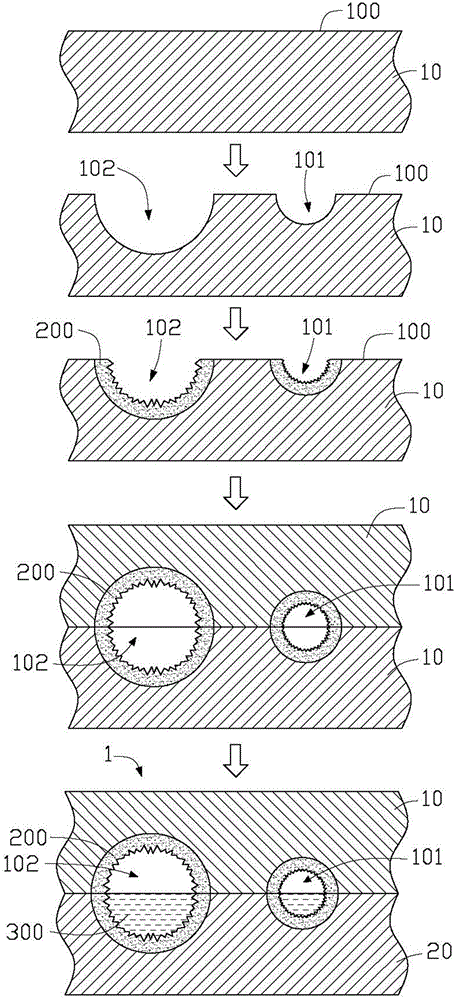

[0015] see figure 1 , the first embodiment of the present invention provides a method for manufacturing a plate-type pulsating heat pipe 1, including the following steps:

[0016] Two plate bodies 10 matching in shape are provided. The material of the plate body 10 is metal or alloy, such as magnesium-aluminum alloy, aluminum alloy, magnesium alloy, aluminum, copper and the like. In this embodiment, the board body 10 is a pure copper board. Each plate body 10 includes a flat surface 100 .

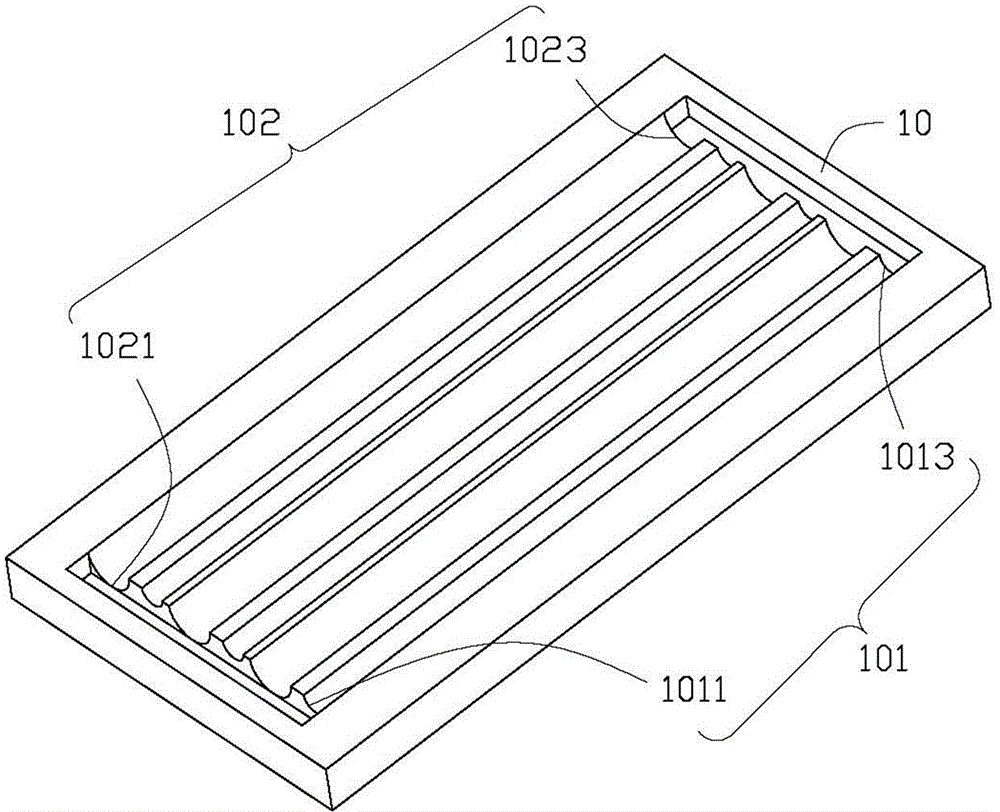

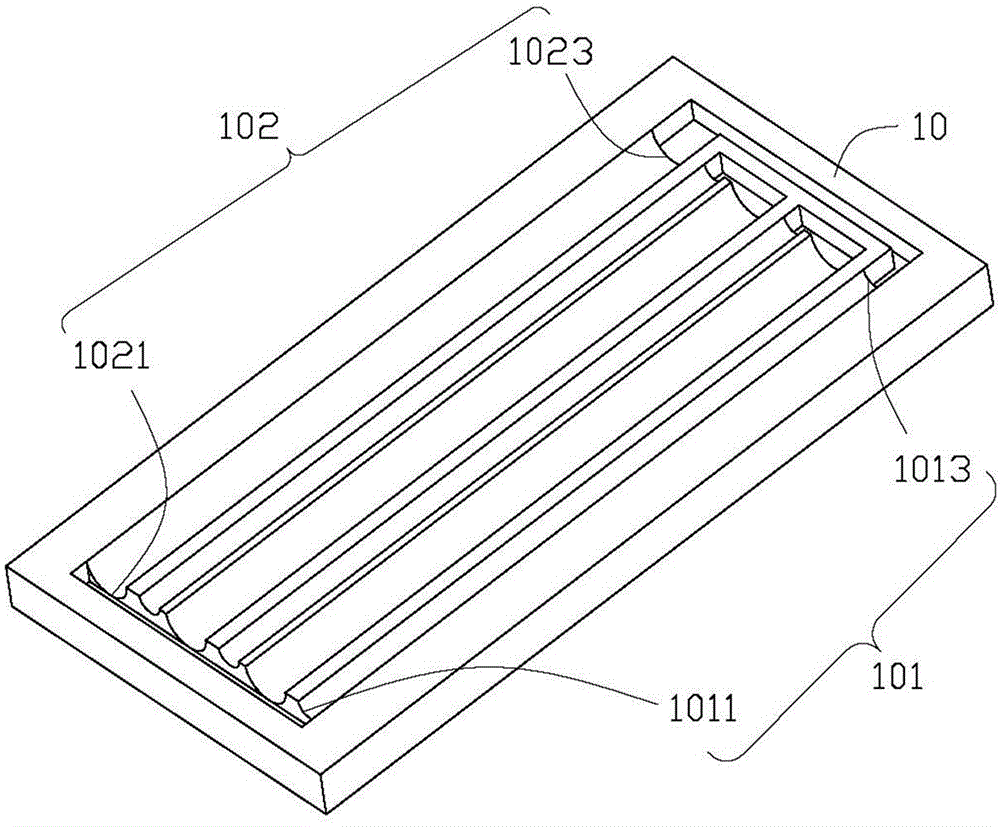

[0017] The surfaces 100 of the two boards 10 are respectively etched to form a plurality of parallel and interconnected first grooves 101 and second grooves 102 on the surfaces 100 of the two boards 10 ( figure 1 Each plate body 10 only shows one first groove 101 and one second groove 102 ). Wherein, the first groove 101 and the second groove 102 of each plate body 10 are arranged at intervals, and the width of the first groove 101 is smaller than the width of the second groove 102 . M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com