Semiconductor device and associated method of manufacture

A semiconductor and device technology, applied in the field of reduced surface field devices and trench Schottky diodes, can solve the problems of semiconductor devices that do not provide breakdown voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

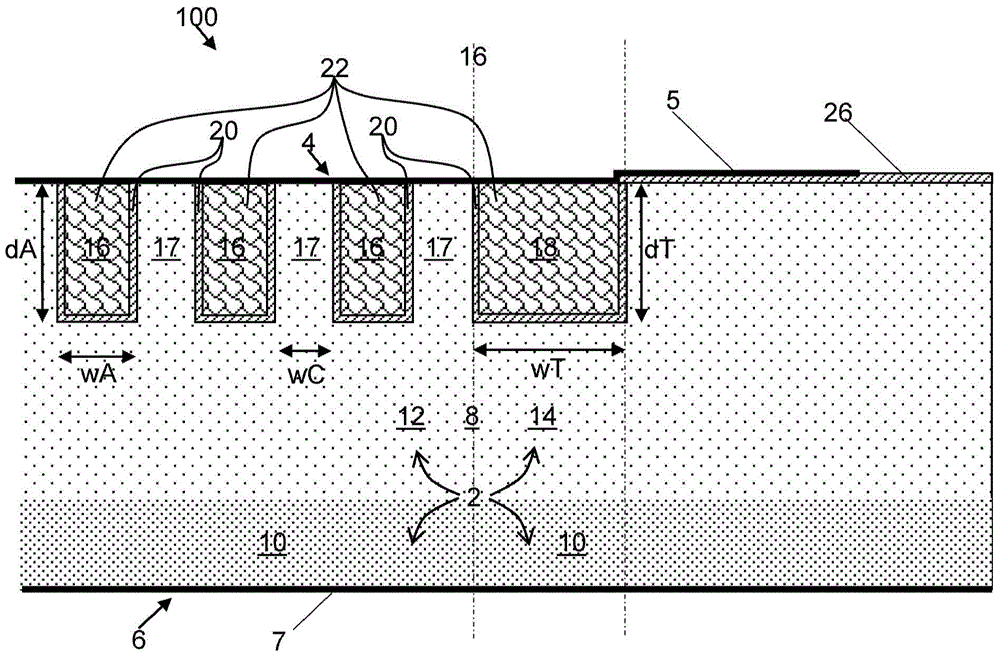

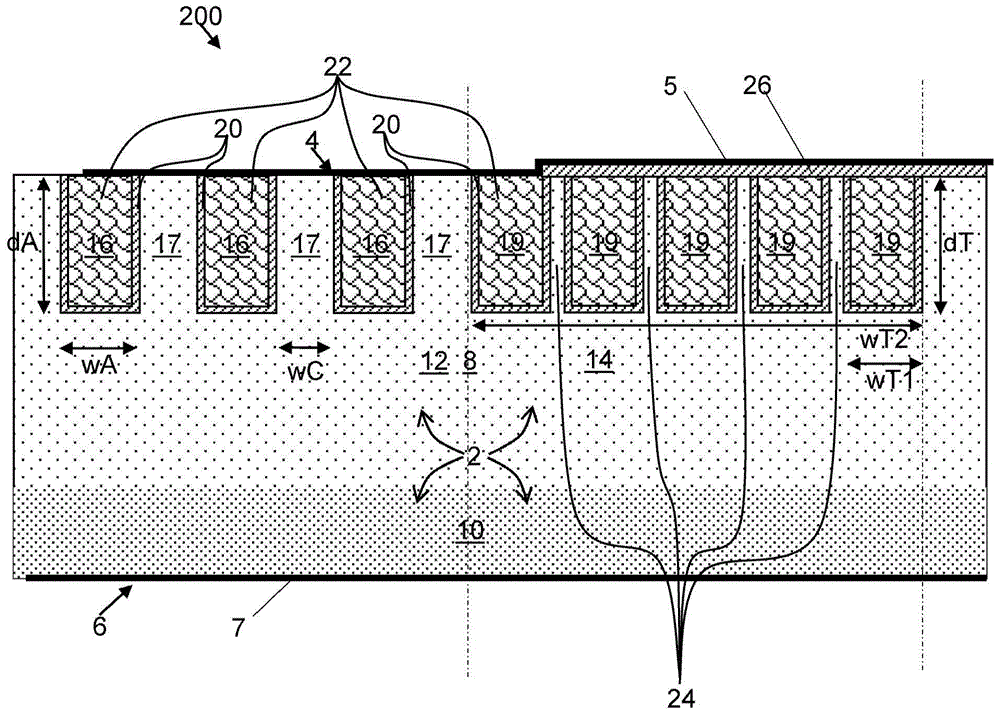

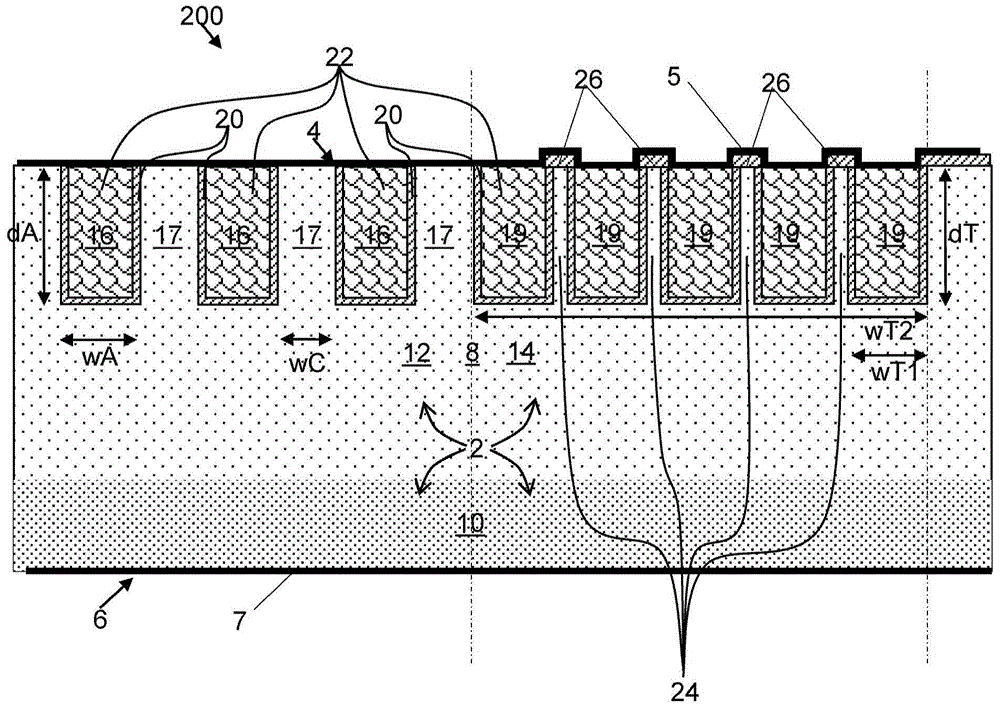

[0052] figure 1 A first semiconductor device 100 is shown. In general terms, device 100 uses a termination trench 18 that is wider than trench 16 in the active area of the device. The width of the termination trench 18 can be designed such that field symmetry in the active area adjacent to the termination trench 18 can be ensured and so that the termination trench 18 can still be filled with polysilicon. The proposed termination design uses wider trenches in the termination region to ensure the symmetry of the electric field in the outermost mesa and prevent premature reverse bias breakdown during operation.

[0053] The device 100 comprises a body 2 having a first surface 4 and an opposite second surface 6 . The first semiconductor layer 8 is disposed in the body 2 and adjacent to the first surface 4 . The second semiconductor layer 10 is arranged adjacent to the second surface 6 . The first semiconductor layer 8 contains a drift region, and is an epitaxial layer that h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com