Ultrasonic field and rectangular pulsed electric field parallel coupling extraction method and device

A rectangular pulse, parallel coupling technology, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of remarkable parallel coupling effect, insufficient ultrasonic-electrostatic field orthogonal coupling, cavitation bubble collapse, etc. Extraction time, improving extraction yield, and the effect of low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

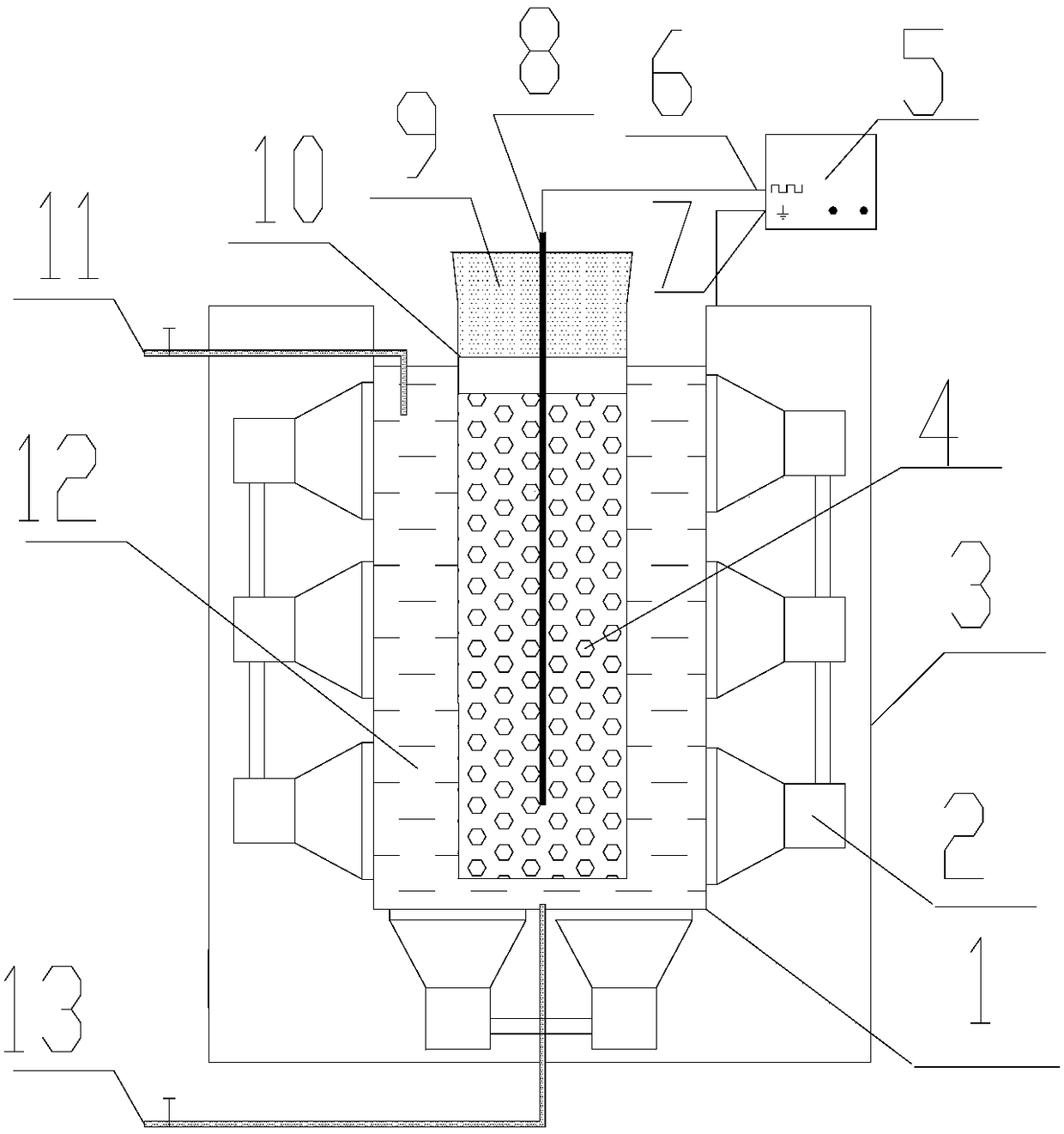

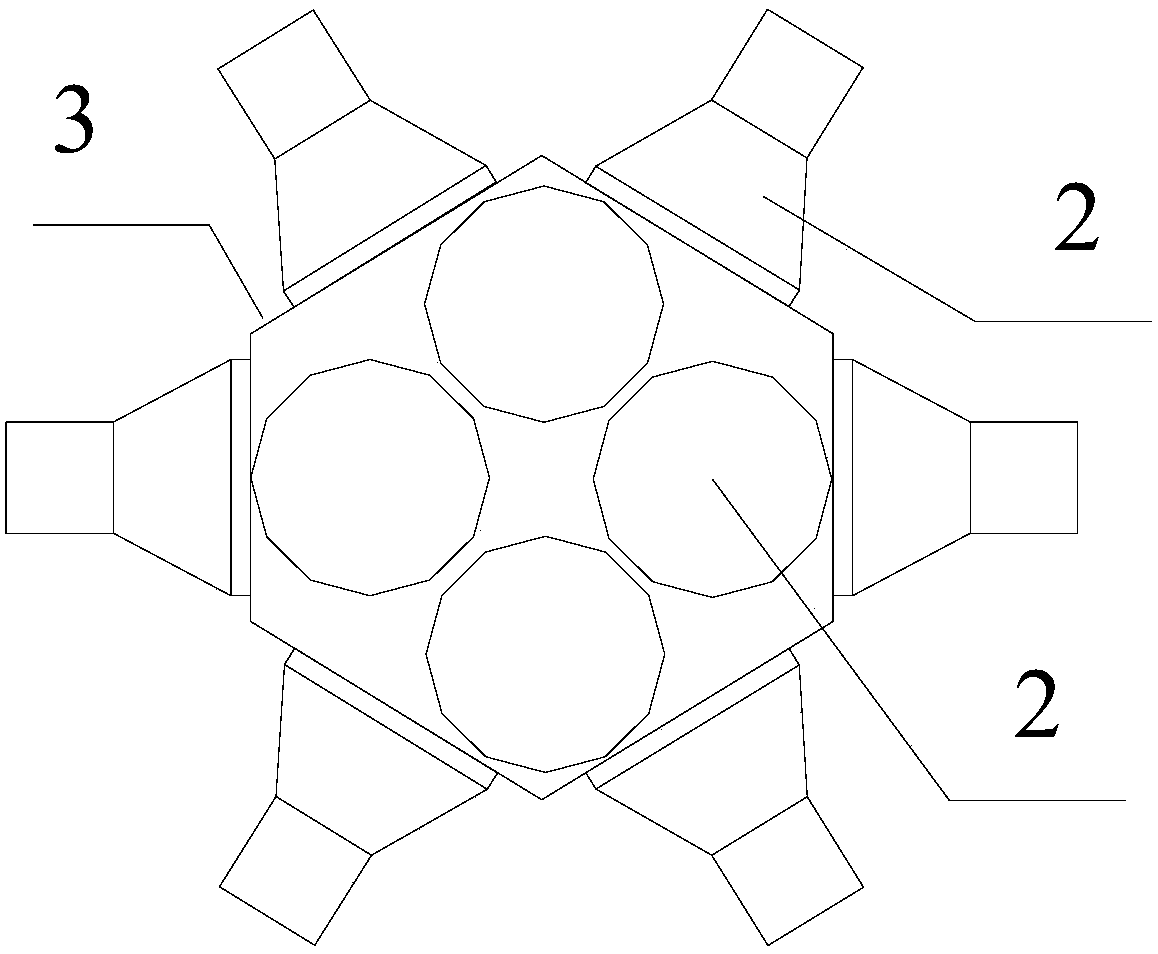

[0032] The extraction by the parallel coupling extraction device of the ultrasonic field and the rectangular pulsed electric field is carried out as follows: the day lily is dried, crushed, and passed through a 60-mesh sieve for pretreatment. Weigh 2 g of daylily coarse powder, put it into a large flat-bottomed test tube, add 50 mL of 70% ethanol solution, fix the central electrode in the center of the large flat-bottomed test tube with a rubber stopper, and fix the large flat-bottomed test tube on the hexagonal cylinder with an iron stand In the center of the extraction tank, the constant temperature water temperature is 55°C, the ultrasonic frequency is 20kHz, and the ultrasonic power density is 3.5W / cm 2 , Rectangular pulsed electric field voltage ±7kV duty cycle 50%, ultrasonic field and rectangular pulsed electric field parallel coupling treatment for 30min, shutdown, filtrate sampling analysis, day lily flavonoids extraction rate was 1.62%.

Embodiment 2

[0034]Dry the daylily, crush it, and pass through a 60-mesh sieve for pretreatment. Weigh 2 g of daylily coarse powder, put it into a large flat-bottomed test tube, add 50 mL of 60% ethanol solution, fix the central electrode in the center of the large flat-bottomed test tube with a rubber stopper, and fix the large flat-bottomed test tube on the hexagonal cylinder with an iron stand In the center of the extraction tank, the constant temperature water temperature is 35°C, the ultrasonic frequency is 40kHz, and the power density is 5W / cm 2 , Rectangular pulse electric field voltage ±15kV, duty cycle 10%, ultrasonic field and rectangular pulse electric field parallel coupling treatment for 20min, shutdown, filtrate sampling analysis, day lily flavonoids extraction rate 1.48%.

Embodiment 3

[0036] Dry the daylily, crush it, and pass through a 60-mesh sieve for pretreatment. Weigh 2 g of daylily coarse powder, put it into a large flat-bottomed test tube, add 50 mL of 60% ethanol solution, fix the central electrode in the center of the large flat-bottomed test tube with a rubber stopper, and fix the large flat-bottomed test tube on the hexagonal cylinder with an iron stand In the center of the extraction tank, the constant temperature water temperature is 75°C, the ultrasonic frequency is 20kHz, and the power density is 1W / cm 2 , Rectangular pulsed electric field voltage ±20kV duty cycle 90%, ultrasonic field and rectangular pulsed electric field parallel coupling treatment for 50min, shut down, filtrate sampling analysis, day lily flavonoids extraction rate was 1.38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com