Meidum- and high-carbon steel plate laser welding method and device

A laser welding, medium and high carbon technology, used in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of poor plasticity and toughness of welds, easy fracture of welds, etc., and achieve the effect of improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A hot-rolled plate with the chemical composition shown in Table 1 is used, and the sample size is: 2.0×500×1000mm, and the welding method is adopted with homogeneous materials.

[0032] Chemical composition (wt%) of table 1 experimental steel

[0033]

[0034] The welding scheme is shown in Table 2. The maximum welding power of the welding machine used here is 12kw CO 2 Laser welding device, the laser power used in this test is 12kw, the welding speed is 6m / min, the welding gap distance is 0.05mm, and the laser focal length is -2.5mm.

[0035] Table 2 welding scheme

[0036]

[0037] Corresponding evaluation experiments were carried out on the welded samples, and the experimental results are shown in Table 3.

[0038] Table 3 Weld quality evaluation

[0039]

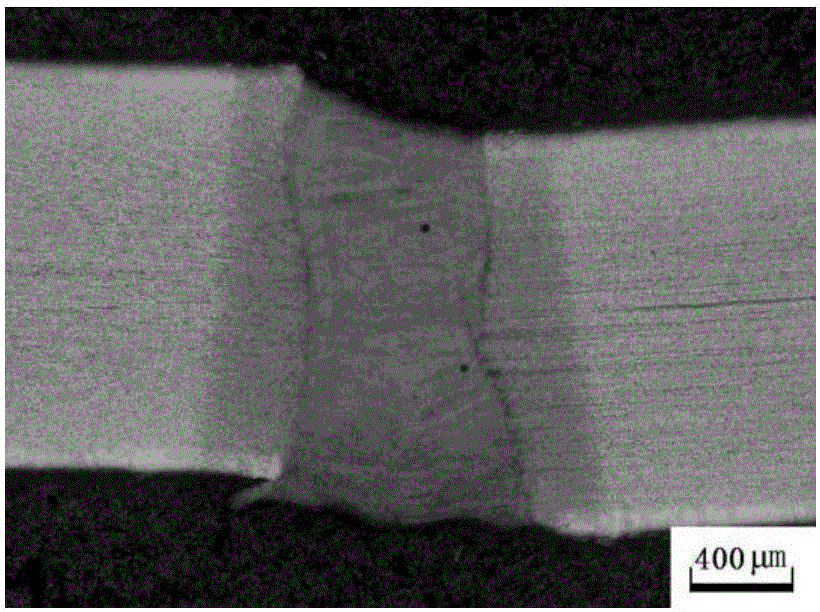

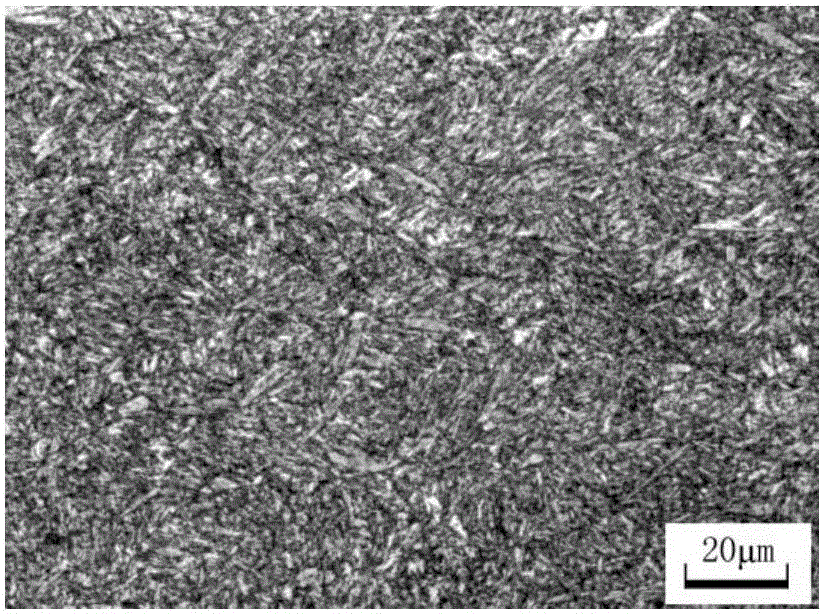

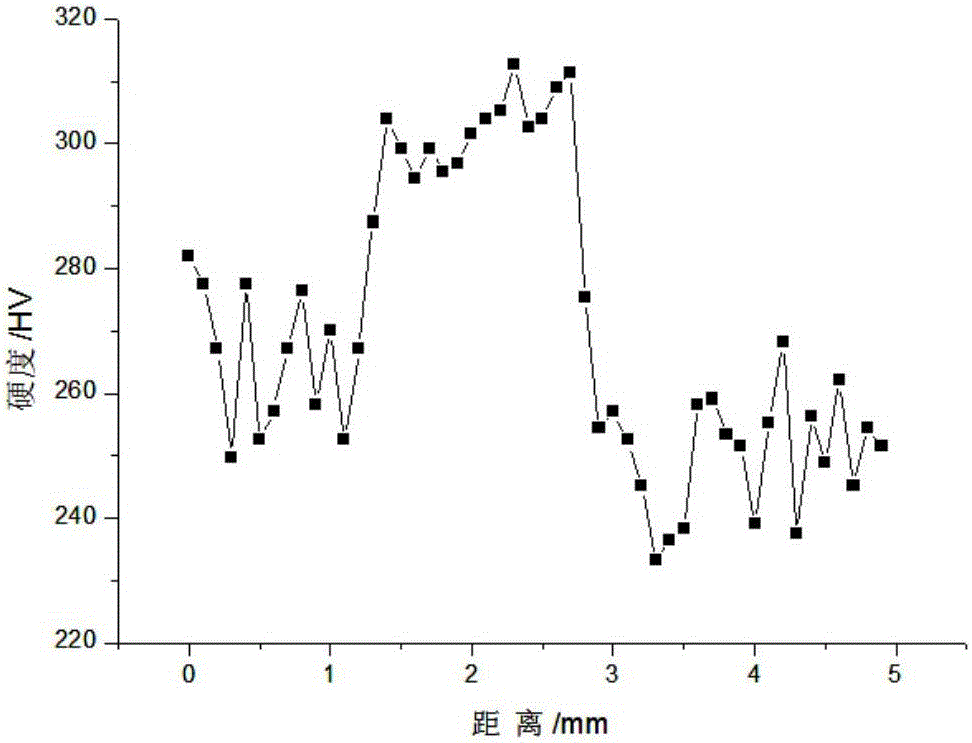

[0040] Observe the weld microstructure after welding, such as figure 1 , figure 2 The tempered sorbite is shown, and the microhardness of the welded structure is tested as image 3 shown.

Embodiment 2

[0042] The hot-rolled plate with the chemical composition shown in Table 4 is used, the sample size is: 2.0×500×1200mm, and the method of welding with homogeneous materials is adopted.

[0043] Chemical composition (wt%) of table 4 experimental steel

[0044]

[0045] The welding scheme is shown in Table 5. The maximum welding power of the welding machine used here is 12kw CO 2 Laser welding device, the laser power used in this test is 8kw, the welding speed is 5m / min, the welding gap distance is 0.06mm, and the laser focal length is -1mm.

[0046] Table 5 welding scheme

[0047]

[0048] Corresponding evaluation experiments were carried out on the welded samples, and the experimental results are shown in Table 6.

[0049] Table 6 Weld quality evaluation

[0050]

[0051] Observe the weld microstructure after welding, such as Figure 4 , Figure 5 The tempered sorbite is shown, and the microhardness of the welded structure is tested as Figure 6 shown.

Embodiment 3

[0053] Use a hot-rolled plate with the chemical composition shown in Table 7. The sample size is: 2.0×500×1200mm, and the method of welding with homogeneous materials is adopted.

[0054] Chemical composition (wt%) of table 7 experimental steel

[0055]

[0056] The welding scheme is shown in Table 8. The maximum welding power of the welding machine used here is 12kw CO 2 Laser welding device, the laser power used in this test is 6kw, the welding speed is 4m / min, the welding gap distance is 0.08mm, and the laser focal length is -0.5mm.

[0057] Table 7 welding scheme

[0058]

[0059] Corresponding evaluation experiments were carried out on the welded samples, and the experimental results are shown in Table 6.

[0060] Table 8 Weld Quality Evaluation

[0061]

[0062] Observe the weld microstructure after welding, such as Figure 7 , Figure 8 The tempered sorbite is shown, and the microhardness of the welded structure is tested as Figure 9 shown.

[0063]From...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com