Apparatus for rapidly and automatically laying thermoplastic composite material member, and method thereof

A composite material component and thermoplastic technology, which is applied in the field of composite material component laying to achieve the effects of realizing crystallinity and grain size, improving interface bonding, and saving time for laying and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

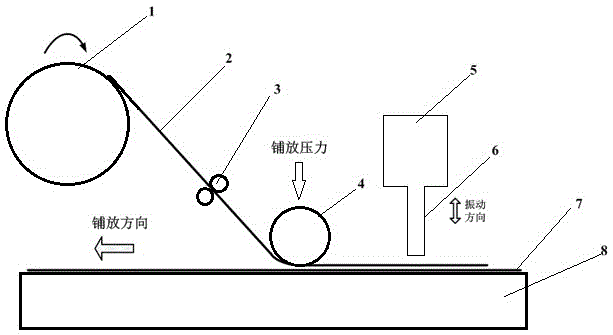

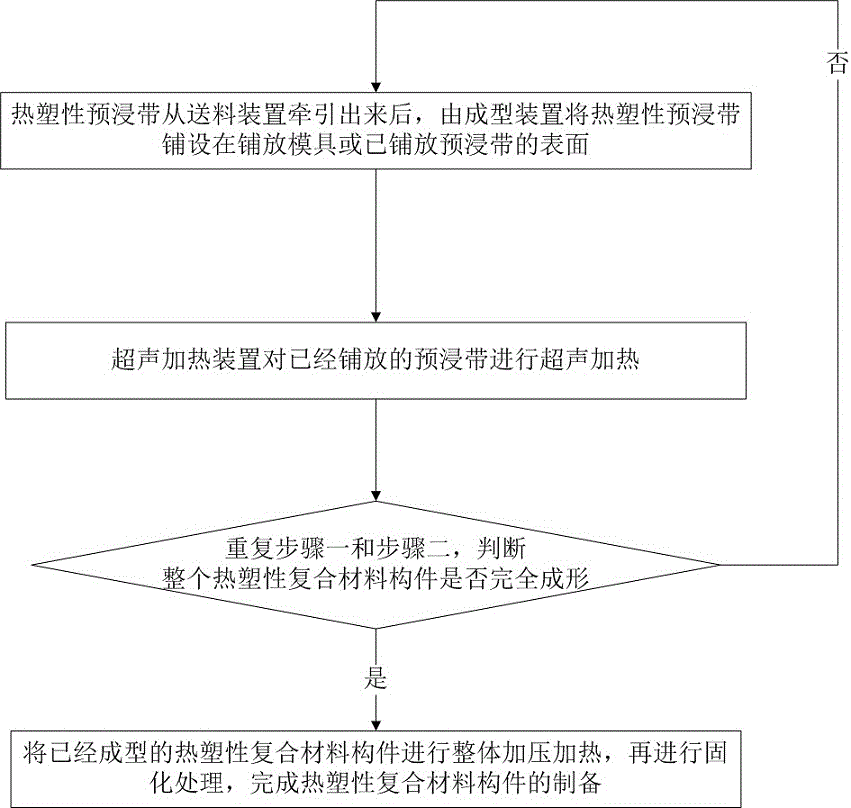

[0023] refer to figure 1 As shown, a device for quickly and automatically laying thermoplastic composite components of the present invention includes: a feeding device for pulling thermoplastic prepreg tapes, a molding device for laying thermoplastic prepreg tapes provided by the feeding device, The ultrasonic heating device used for ultrasonically heating the thermoplastic prepreg tape laid by the forming device, the feeding device, the forming device, and the ultrasonic heating device are all arranged on the laying mold. Further, specifically, the feeding device includes a tray 1, a pair of feeding rollers 3; the molding device includes a pressure roller 4, an ultrasonic heating device 6 and a motor 5; and a prepreg tape 2, a laid prepreg tape 7 and Lay out the mold 8. The invention utilizes ultrasonic vibrations to realize rapid posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com