City rail traffic traction system

An urban rail transit and traction system technology, applied in the field of urban rail transit traction systems, can solve problems such as potential safety hazards and increase project cost, and achieve the effect of reducing project cost and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

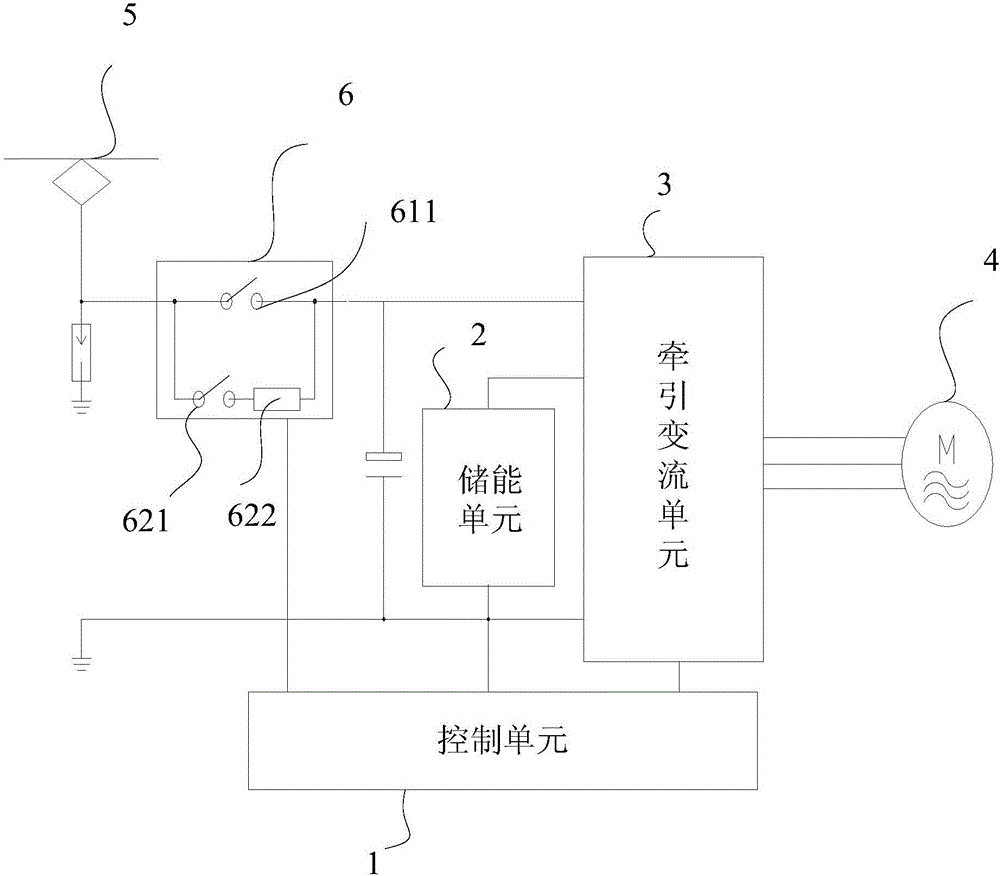

Embodiment 1

[0024] figure 1 The structural representation of the urban rail transit traction system provided for Embodiment 1 of the present invention, such as figure 1 As shown, the urban rail transit traction system provided by this embodiment includes: a control unit 1, an energy storage unit 2, a traction converter unit 3 and a traction motor 4, wherein the traction converter unit 3 is connected to the two direct currents of the external power supply unit 5 Between the busbars, the energy storage unit 2 is respectively connected to a DC busbar of the external power supply unit 5 and the traction converter unit 3, the energy storage unit 2 is used to store the electric energy provided by the external power supply unit 5, and the traction converter unit 3 is respectively connected to the control unit 1 is connected to the traction motor 4, and the control unit 1 is used to control the traction converter unit 3 to charge and store and / or discharge the energy storage unit 2, and convert t...

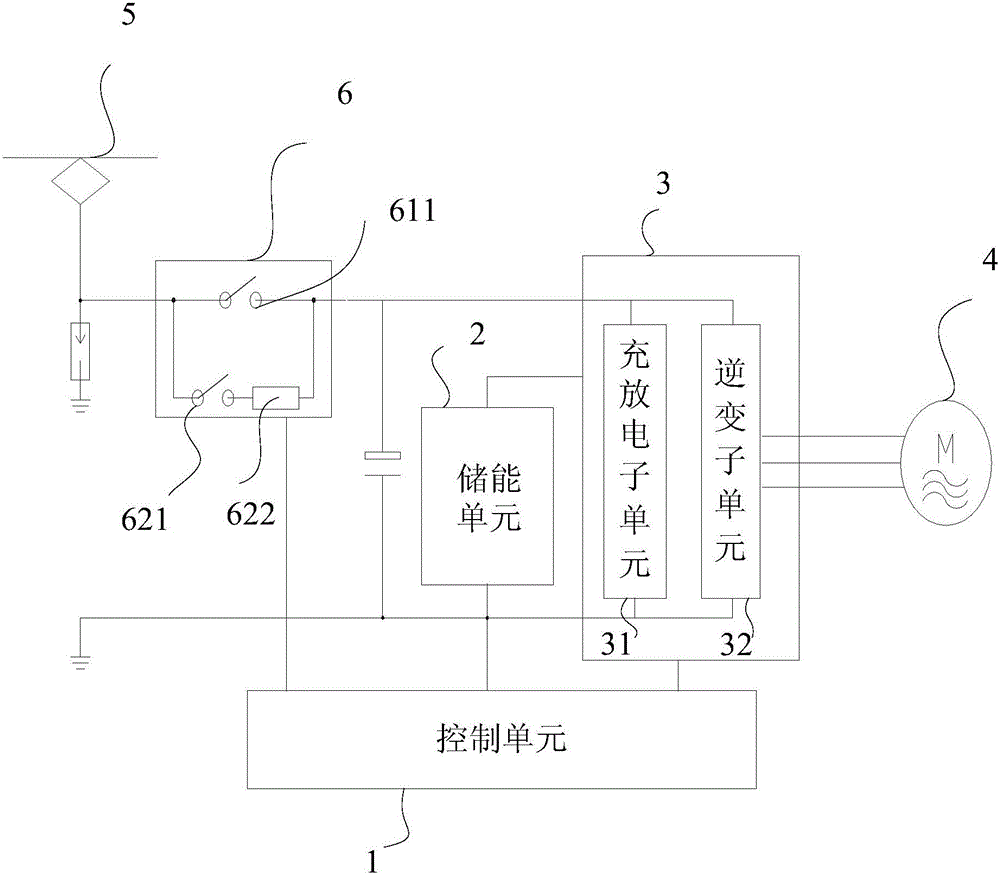

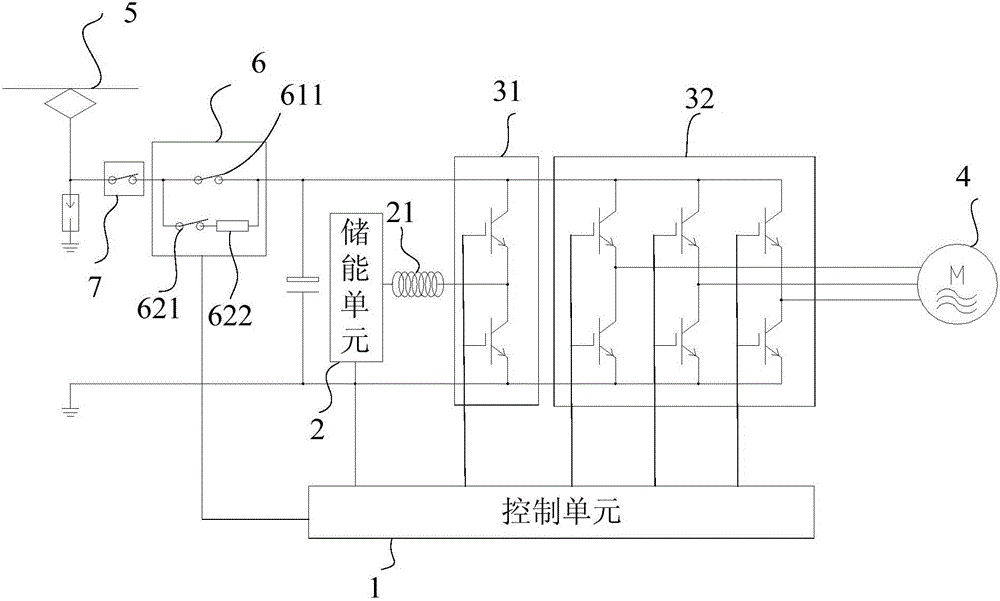

Embodiment 2

[0030] On the basis of the above examples, if figure 1 As shown, the urban rail transit traction system provided by this embodiment also includes: a switch switching unit 6 connected between the external power supply unit 5 and the traction converter unit 3, and the switch switching unit 6 includes: a first switch branch and a first switch branch connected in parallel with each other. The second switch branch, wherein the first switch branch includes a first switch 611 , and the second switch branch includes a second switch 621 and a current limiting resistor 622 connected in series. The switch switching unit 6 is also connected to the control unit 1 , and the control unit 1 is used to control the closing or opening of the first switch 611 and the second switch 621 .

[0031] Specifically, when the train decelerates and enters the station, the control unit 1 controls the second switch 621 to close, the current-limiting resistor 622 performs current-limiting charging control, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com