Water surface cleaning ship with turnover type rear cabin

A cleaning boat and flip-up technology, which is used in the cleaning of open water surfaces, general water supply saving, water conservancy projects, etc., can solve the problems of shortening the length of the cleaning boat, and achieve the effects of simple structure, ingenious design and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

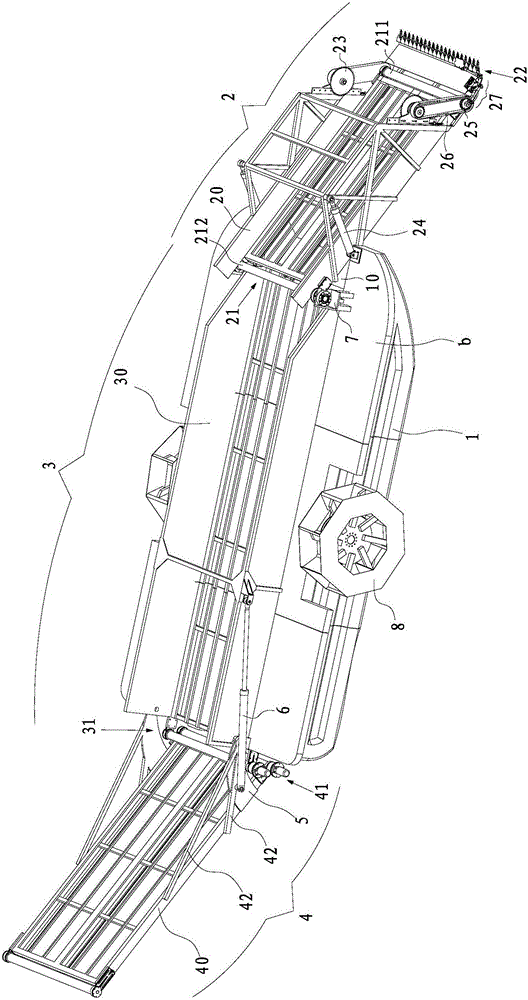

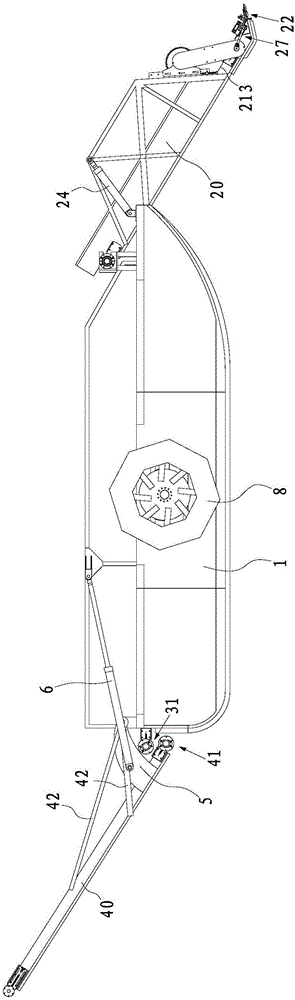

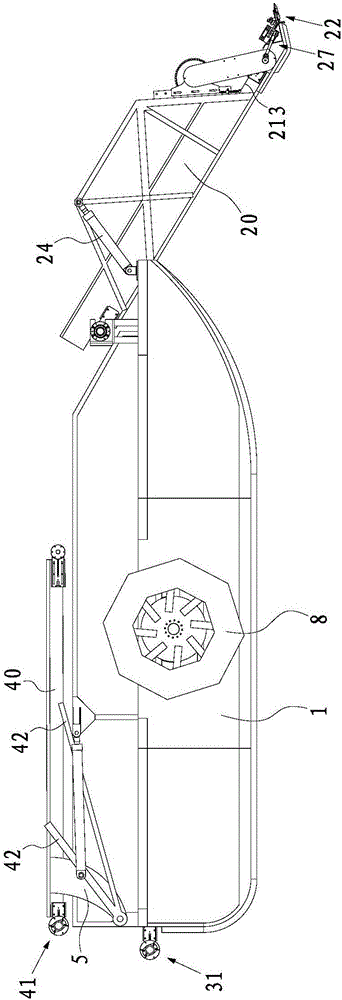

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see picture 1 to figure 3 , the surface cleaning ship provided by this embodiment, which includes the hull 1 , acquisition device 2 , storage device 3 and unloading device 4 , where the storage device 3 located on the hull 1 the middle part of the collection device 2 and unloading device 4 located on the hull 1 head and tail.

[0024] In this example, the surface cleaning vessel also includes 3 Both sides of the tail, with one end passing through the pivot a and storage 3 Rotate to connect the other end with the unloading device 4 Connectors for fixed connections 5 ; in storage 3 Both sides, and one end and connecting piece 5 Rotate to connect the other end with the storage device 3 The first hydraulic cylinder corresponding to the side turn connection 6 , where wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com