High-efficiency self-control horizontal rotary-electrode electro-catalysis oxidation dirt removal device

A catalytic oxidation, horizontal technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low cost of wastewater treatment, complete commercialization of low-cost large-scale treatment projects, etc., and achieve improvement Speed and sufficiency, ensuring stability, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

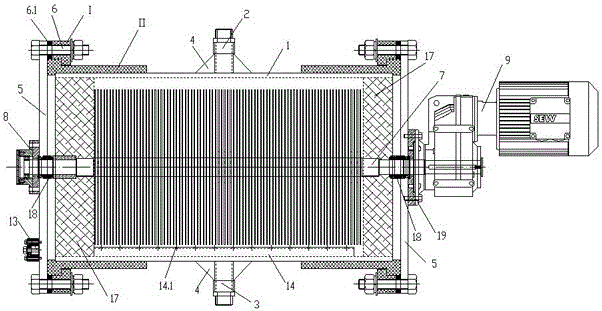

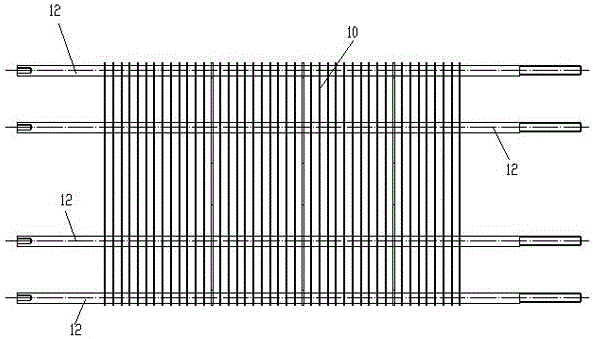

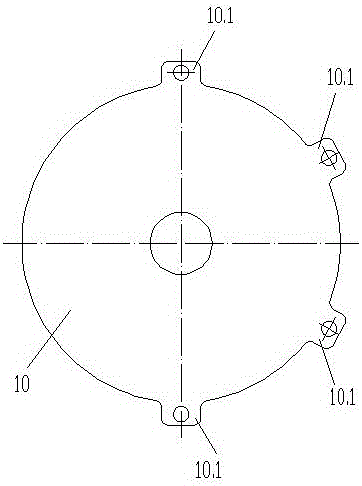

[0022] Embodiment 1: High-efficiency self-controlled horizontal pole-rotating electrocatalytic oxidation decontamination device, including a cylinder body 1, inlet and outlet pipes (2, 3) relatively arranged in the center of the side wall of the cylinder body 1, inlet and outlet pipes (2, 3 ) is provided with a pipeline reinforcement plate 4, both ends of the cylinder body 1 are provided with end caps 5 for sealing, and the end caps 5 at both ends of the cylinder body 1 are provided with flanges, and the flanges are provided with connection holes around the center of the circle, and the cylinder body 1 Both ends are provided with insulating parts, the insulating parts include the insulating sleeve I and the insulating sleeve II set on the end of the cylinder, and the insulating sleeve II is sleeved on the fixing bolt 6. The sealing gasket 6.1 and the fixing bolt 6 pass through the connecting holes on the flange sides of the end caps 5 at both ends of the cylinder body 1, and ar...

Embodiment 2

[0023] Embodiment 2: With reference to Embodiment 1, the water distribution pipe 14 is a shell made of round pipe, channel steel or angle steel. The size of the openings on the water distribution pipe 14 is calculated according to the water inflow. It is: holes are uniformly opened at both ends, and the cross-sectional area of the openings at both ends accounts for 80% of the total cross-sectional area of the water distribution pipe. .

Embodiment 3

[0024] Embodiment 3: Referring to Embodiment 1 or 2, the inner cavity of cylinder body 1 is filled with catalytic packing or activated carbon 17, and the activated carbon is activated carbon sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com