Double-wall reinforced plastic septic tank

An enhanced, septic tank technology, applied in the direction of biological sludge treatment, etc., can solve the problems of easy leakage of septic tanks, slow project progress, long construction period, etc. The effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

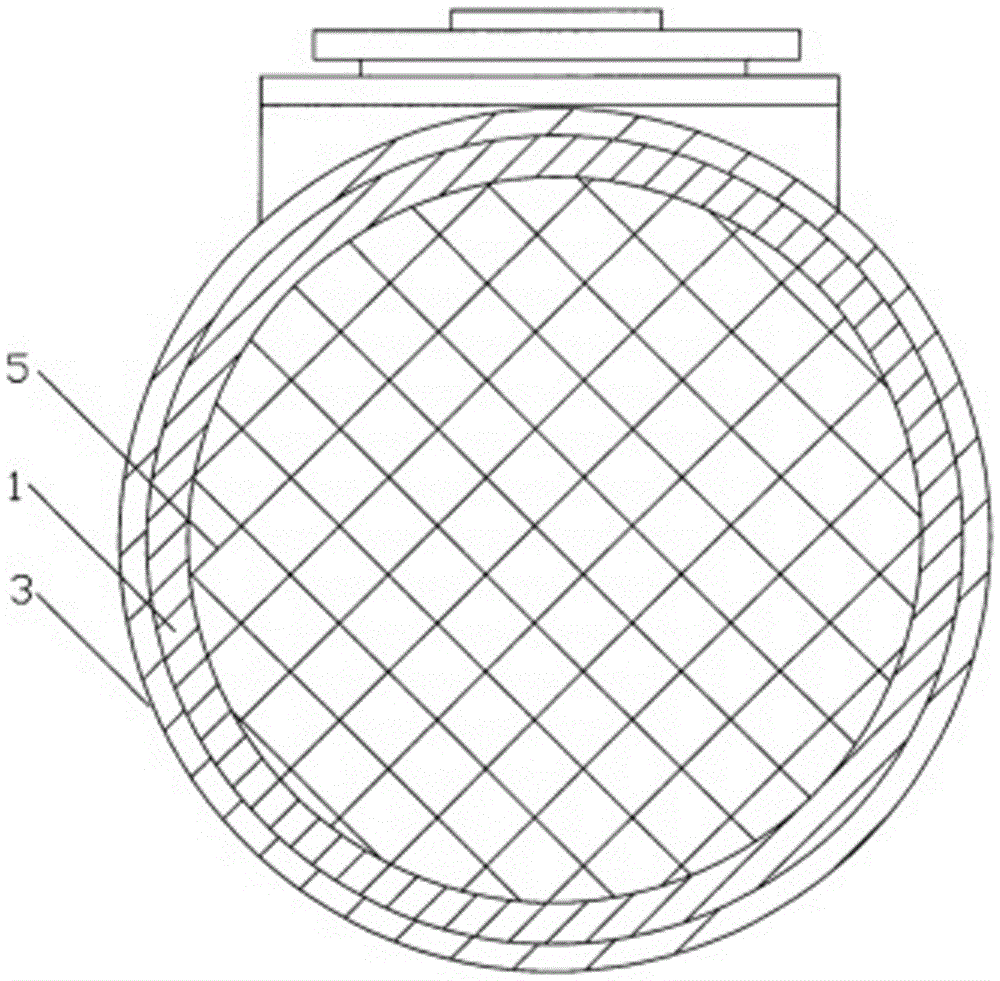

[0011] refer to Figure 1-2 , which is composed of a cylindrical cylinder 1 and a head 2 arranged at both ends of the cylinder, on the outer wall of the cylinder, a number of fastening rings 3 are arranged side by side along the circumferential direction, and the section of the fastening ring is a semicircle shape, and radial ribs 4 are provided on the surface of the head. In addition, a screen-like partition 5 is arranged radially in the cylinder, which not only plays the role of sedimentation and filtration, but also has the function of bearing pressure.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap