Method for reducing alcoholic strength in period of storing white spirit in oak barrel

A technology of oak barrels and liquor, applied in the preparation of alcoholic beverages, etc., can solve the problems of weak wine body, mixed wine body, increased production cost, etc., and achieves the effect of strong taste and long aftertaste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

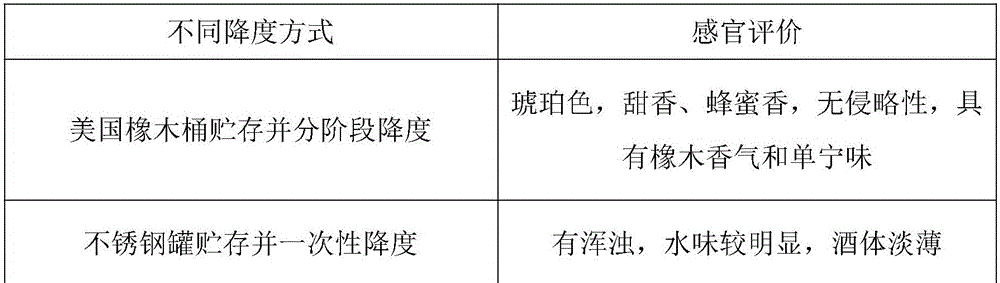

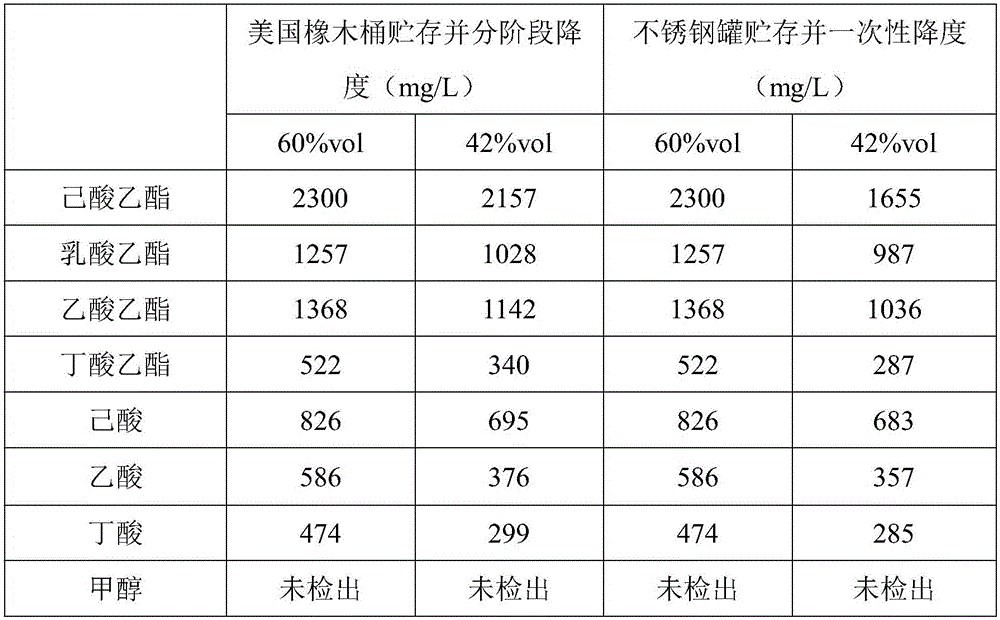

[0023] Store liquor in 225L American oak barrels, alcohol content 60% vol, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room at a temperature of 25°C , humidity 70%, after 3 months of storage, pour the liquor in the oak barrel into another oak barrel and add water until the barrel is full to reduce 5% vol, and store it under the same environmental conditions, repeat the above after 3 months Operate until it reaches 42% vol, take samples for sensory evaluation and determine the main aroma components; the same batch of wine samples are stored in stainless steel tanks under the same environmental conditions for the same time and reduce the concentration to 42% vol at one time, take samples for sensory evaluation, Determination of the main aroma components, the results of the measurement are shown in Table 1 and Table 2.

[0024] Table 1 Sensory evaluation results after ...

Embodiment 2

[0030] Store liquor in 225L American oak barrels, alcohol content 52% vol, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room at a temperature of 25°C , humidity 70%, after 3 months of storage, pour the liquor in the oak barrel into another oak barrel and add water until the barrel is full to reduce 5% vol, and store it under the same environmental conditions, repeat the above after 3 months Operate until it reaches 42% vol, take samples for sensory evaluation and determine the main aroma components; the same batch of wine samples are stored in stainless steel tanks under the same environmental conditions for the same time and reduce the concentration to 42% vol at one time, take samples for sensory evaluation, Determination of main aroma components, measurement results are shown in Table 3 and Table 4.

[0031] Table 3 Sensory evaluation results after different reduc...

Embodiment 3

[0037] Store liquor in 350L French oak barrels, alcohol content 60% vol, cover the oak barrel lid (not completely sealed) for the first 2 days, then completely seal the barrel lid of the oak barrel, and place it in a cool and dry room at a temperature of 22°C , humidity 65%, after 3 months of storage, pour the liquor in the oak barrel into another oak barrel and add water until the barrel is full to reduce 5% vol, and store it under the same environmental conditions, repeat the above after 3 months Operate until it reaches 42% vol, take samples for sensory evaluation and determine the main aroma components; the same batch of wine samples are stored in stainless steel tanks under the same environmental conditions for the same time and reduce the concentration to 42% vol at one time, take samples for sensory evaluation, Determination of the main aroma components, the results of the measurement are shown in Table 5 and Table 6.

[0038] Table 5 Sensory evaluation results after di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com