Walking pushing system

A technology of jacking and jacking, which is applied in the erection/assembly of bridges, bridges, buildings, etc. It can solve the problems of large work and placement space, complex sliding box structure, and large work space, so as to save bridge construction costs and expand scalability Strong, small workspace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

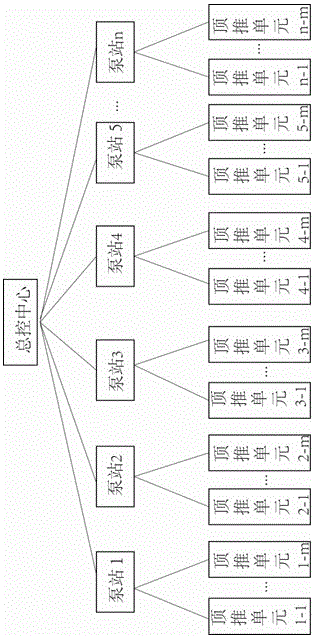

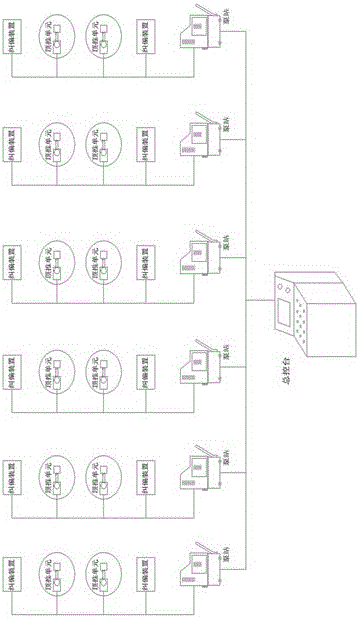

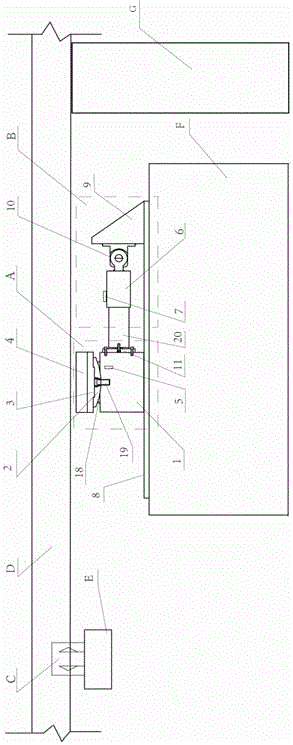

[0047] In this embodiment, a master control center, n hydraulic pump stations, and n×m pushing units are provided; the pushing units are as follows: figure 2 As shown, there is a lifting device A, a pushing device B, and a deviation correcting device C. The n×m pushing units are symmetrically distributed on both sides of the component axis, such as Figure 9 shown.

[0048] The lifting device A is provided with a lifting jack 1, a spherical plate 2, a comb plate 3, a backing plate 4, and a displacement sensor 5; The top of the piston 18 of the lifting jack 1 is a concave spherical surface, and the spherical plate 2 is as Figure 6 , 7 As shown, the bottom end is a convex spherical surface, which matches the concave spherical surface of the piston 18. The spherical plate 2 and the jacking jack piston 18 are kept centered by the bolt 19 arranged at the center of the circle, so that the spherical plate 2 can swing along the spherical surface , to adjust the self-leveling and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com