Positioning frame for prefabricated pier column reinforcing bar cages and construction method of pier column reinforcing bar cages

A steel cage and positioning frame technology, which is applied in the processing of building materials, structural elements, building components, etc., can solve the problems of unqualified steel protective layer, affecting the service life of structures, and large thickness of steel protective layer, so as to reduce the high-altitude Effects of operation and crane operation time, improvement of construction progress and project quality, and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

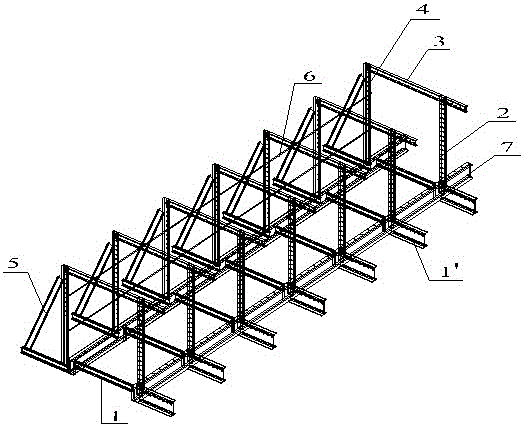

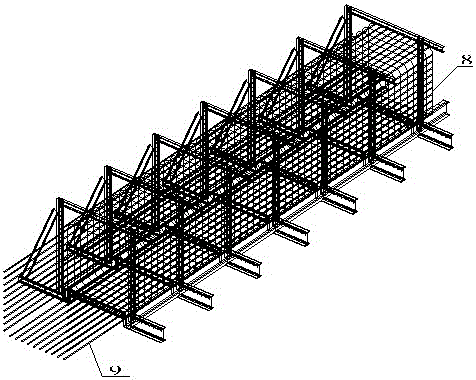

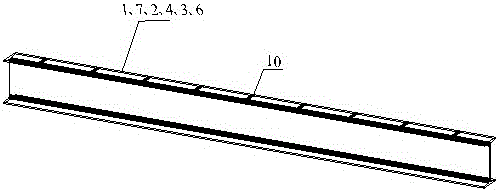

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a positioning frame for a prefabricated pier column reinforcement cage includes a base, and the base includes several bottom main reinforcement positioning beams 1 and two bottom bottom stirrup positioning beams 7, each bottom main reinforcement positioning beam 1 and each bottom bottom stirrup positioning beam 7 are vertical set up. The main reinforcement positioning beams 1 of each bottom layer are parallel to each other, and the two bottom stirrup positioning beams 7 are also arranged parallel to each other.

[0032] The intersection of each bottom main reinforcement positioning beam 1 and a left bottom stirrup positioning beam 7 is vertically provided with a left side main reinforcement positioning beam 4, and each bottom main reinforcement positioning beam 1 intersects with a right bottom stirrup positioning beam 7 Both are vertically provided with the side main reinforcement positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com