A cascaded thermoacoustic power generation device

A technology for power generation devices and generators, which is applied to machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc., can solve the problems of large volume of cascade thermoacoustic engines, large energy loss of resonance tubes, and uncompact structure, and achieves The effect of compact structure, elimination of resonance tubes, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

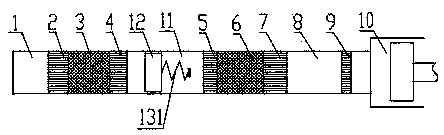

[0028] Such as figure 1 As shown, the cascade thermoacoustic power generation device provided in this embodiment includes a standing wave motor and a traveling wave motor, a phase-modulated resonator is connected between the standing wave motor and the traveling wave motor, and the traveling wave motor is A generator 10 is connected.

[0029] Wherein, the phase modulation resonator includes a phase modulation cylinder 11 , a phase modulation piston 12 arranged in the phase modulation cylinder 11 , and a return spring 131 connected to the phase modulation piston 12 . The standing wave engine includes a thermal cavity 1, a standing wave heater 2, a plate stack 3 and a standing wave water cooler 4 connected in sequence from left to right, wherein the standing wave water cooler 4 is connected to the left end of the phase-modulating cylinder 11 connected. The traveling wave engine includes a traveling wave main water cooler 5, a regenerator 6, a traveling wave heater 7, a thermal...

Embodiment 2

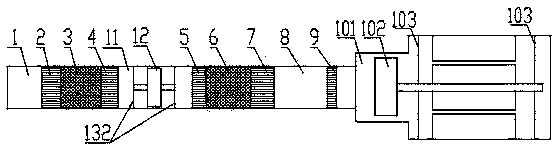

[0035] Such as figure 2 As shown, the cascade thermoacoustic power generation device provided by this embodiment includes a standing wave motor and a traveling wave motor, a phase-modulated resonator is connected between the standing wave motor and the traveling wave motor, and the traveling wave motor is There is a generator connected. Wherein the structures of the standing wave motor and the traveling wave motor are the same as that of Embodiment 1, only the structures of the phase modulation resonator and the generator are different.

[0036]Specifically, a phase modulation piston 12 is provided in the phase modulation cylinder 11 of the phase modulation resonator, and a return leaf spring 132 is respectively provided at both ends of the phase modulation piston 12, and the two ends of the phase modulation piston 12 The ends are respectively connected with the return leaf spring 132 through the piston rod. Since the phase modulation resonator adopts the return plate sprin...

Embodiment 3

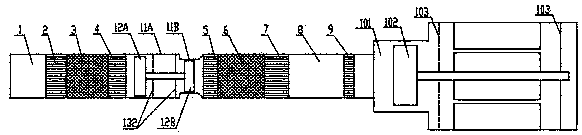

[0039] Such as image 3 As shown, the cascade thermoacoustic power generation device provided in this embodiment includes a standing wave motor and a traveling wave motor, a phase-modulated resonator is connected between the standing wave motor and the traveling wave motor, and the traveling wave motor is There is a generator connected. Wherein the structures of the standing wave motor, the traveling wave motor and the generator are the same as those of the second embodiment, only the structure of the phase-tuned harmonic oscillator is different.

[0040] Specifically, the phase modulation cylinder includes a first cylinder 11A and a second cylinder 11B, and the phase modulation piston includes a first phase modulation piston 12A and a second phase modulation piston 12B. The first phase-adjusting piston 12A and the second phase-adjusting piston 12B are correspondingly arranged in the first cylinder 11A and the second cylinder 11B, and the first phase-adjusting piston 12A and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com