High-speed rice transplanter comprehensive performance detection test stand

A comprehensive performance and rice transplanter technology, applied in the field of agricultural machinery, can solve the problems of high cost, high labor intensity, etc., and achieve the effect of reasonable structural design, cost reduction, and improvement of testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

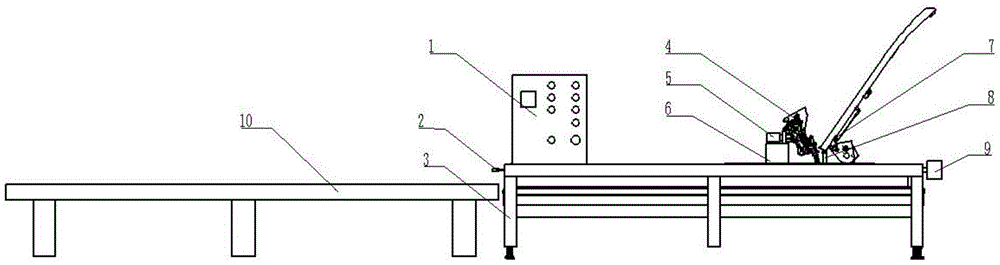

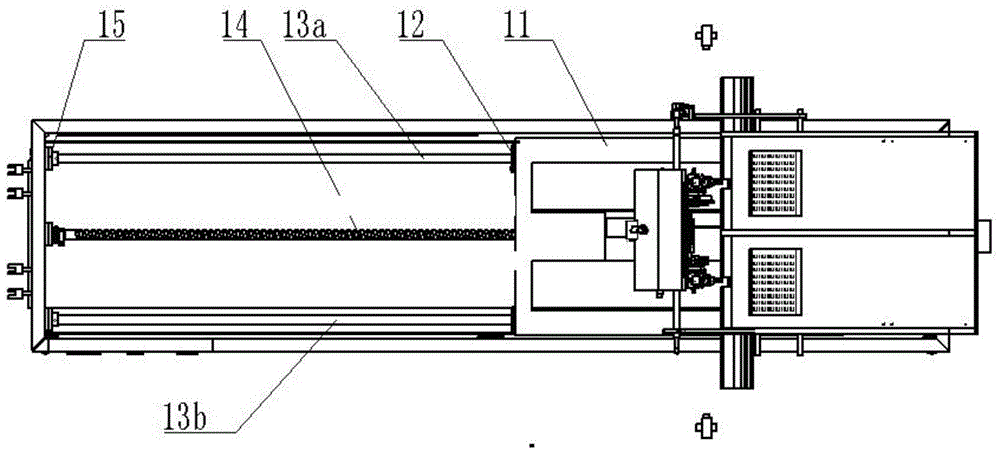

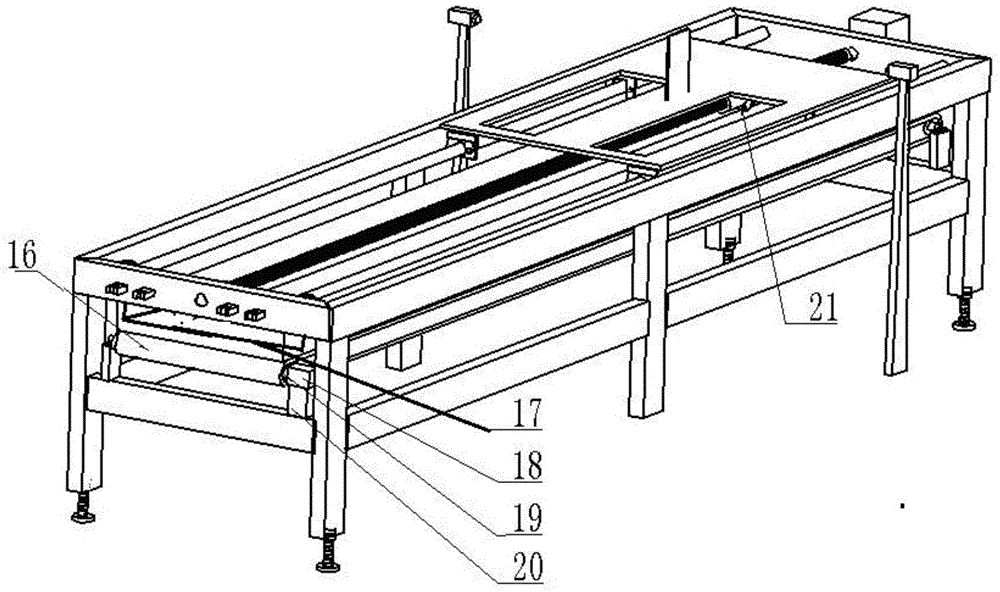

[0032] See attached picture Figure 1-Figure 8 , A high-speed rice transplanter comprehensive performance testing test bench, the test bench includes: the main frame 3 of the test bench is welded by several long steel pipes, parallel to the ground in a rectangular frame structure, the guide rail It consists of a symmetrical cylindrical guide 13a and a cylindrical guide 13b, a motor 9, a lead screw 14, a support plate 11, and a sliding sleeve 12. The motor 9 and the lead screw 14 are connected by bearings, and the two ends of the cylindrical guide 13 pass through flanges. 15 is fixed to the main frame 3 of the test bench and kept parallel to the ground. The support plate 11 is fixed with four sliding sleeves 12 by bolts. The sliding sleeves 12 can slide in parallel on the cylindrical guides 13, and the planting part to be tested is installed in On the upper end of the pallet 11, adjust the position of the split-planting mechanism 24 on the pallet 3 to ensure that the planting ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com