Testing method for binding strength of putty and waterproof coating for building, high-strength binding agent and application

A technology of bonding strength and waterproof coating, applied in the field of testing construction putty and high-strength adhesive, can solve the problems of low success rate and fluctuation of experimental results, and achieve simple and easy testing method, small data fluctuation, and cost reduction. Effects of loss and wasted time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

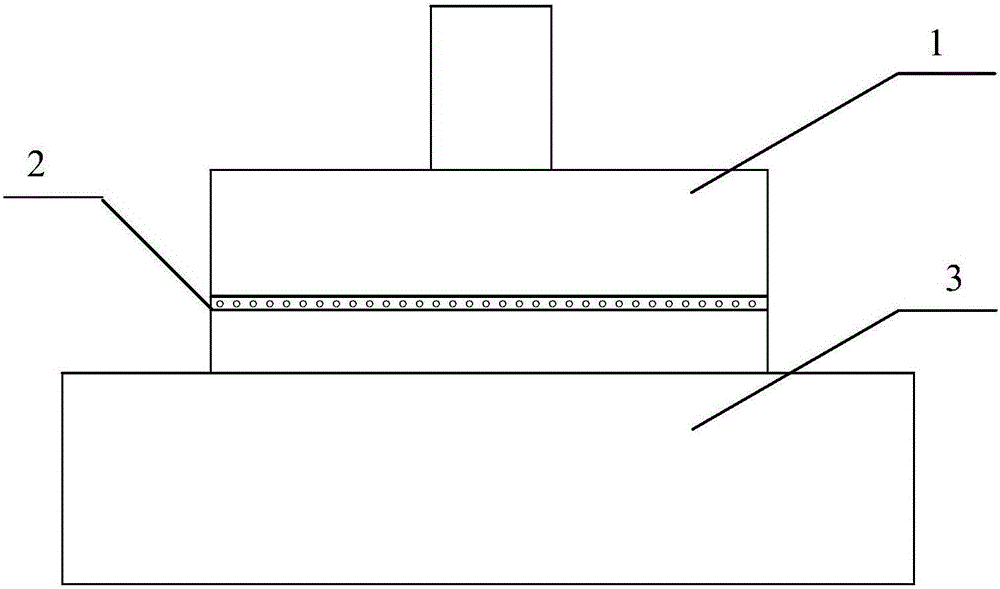

Image

Examples

Embodiment 1

[0055] To test the bonding strength of Kuaitubao flexible waterproof slurry, the method is as follows:

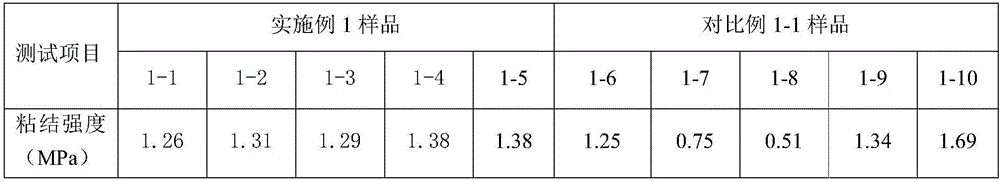

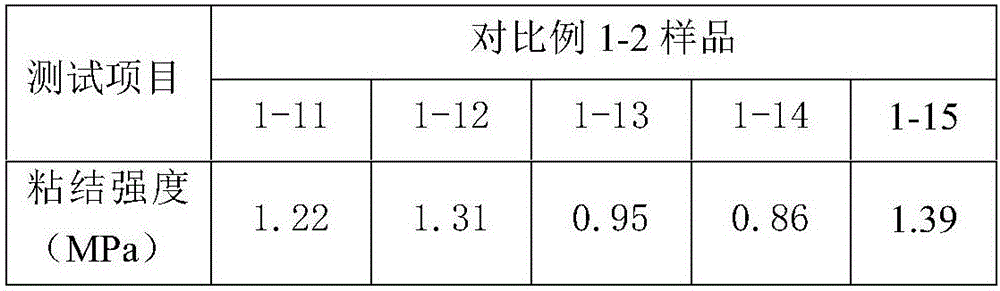

[0056] 1) For the Kuaitubao flexible waterproof slurry to be tested, prepare 10 standard test pieces according to the method of 7.6.2.1-7.6.2.2 in the national standard GB / T23445-2009 of the People's Republic of China and maintain them as required. Good standard test pieces are randomly marked as samples 1-1, 1-2, 1-3, 1-4, 1-5, 1-6, 1-7, 1-8, 1-9, 1-10, 1-11, 1-12, 1-13, 1-14, 1-15;

[0057] 2) Take 20g of NPEL-128 epoxy resin, 10g of BSA-3859 curing agent and 3g of 120-180 purpose natural colored sand respectively, and mix them evenly to obtain a high-strength adhesive;

[0058] 3) Apply the high-strength adhesive obtained by stirring evenly in step 2) quickly and evenly on the standard test piece samples 1-1, 1-2, 1-3, 1-4 and 1- 5 on the coated film surface, according to the method of 7.6.3.1 in the national standard GB / T 23445-2009 of the People's Republic of China, ...

Embodiment 2

[0073] To test the bonding strength of Kuaitubao classic general-purpose waterproof coating, the method is as follows:

[0074] 1) Repeat step 1) of Example 1, the difference is that the Kuaitubao flexible waterproof slurry in step 1) is replaced with Kuaitubao classic general-purpose waterproof coating, and the cured standard test pieces are randomly marked as samples 2- 1, 2-2, 2-3, 2-4, 2-5, 2-6, 2-7, 2-8, 2-9, 2-10, the rest of the conditions remain unchanged;

[0075] 2) Take 20g of NPEL-128 epoxy resin, 10g of BSA-3859 curing agent and 2g of 120-180 purpose natural colored sand respectively, and mix them evenly to obtain a high-strength adhesive;

[0076] 3) Apply the high-strength adhesive obtained by stirring evenly in step 2) quickly and evenly on the standard specimen samples 2-1, 2-2, 2-3, 2-4 and 2- 5 on the coating film surface, measure the viscosity by the method of embodiment 1 step 3).

Embodiment 3

[0086] To test the bond strength of a batch of Lebao Liangjia putty, the method is as follows:

[0087] 1) The batch of Lebao Liangjia putty to be tested is prepared according to the method of 6.12.1-6.12.2.1 in the construction industry standard JG / T 298-2010 of the People's Republic of China, and 10 standard test pieces are prepared and maintained according to the requirements. The cured standard specimens are randomly marked as samples 3-1, 3-2, 3-3, 3-4, 3-5, 3-6, 3-7, 3-8, 3-9, 3-10 , 3-11, 3-12, 3-13, 3-14, 3-15, 3-16, 3-17, 3-18;

[0088] 2) Take 20g of NPEL-128 epoxy resin, 10g of BSA-3859 curing agent and 3g of 120-180 purpose natural colored sand respectively, and mix them evenly to obtain a high-strength adhesive;

[0089] 3) Apply the high-strength adhesive obtained by stirring evenly in step 2) quickly and evenly on the standard test piece samples 3-1, 3-2, 3-3, 3-4, 3- On the coating surface of 5 and 3-6, measure and calculate the bonding strength according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com