Wireless control system of composite material belt rolling main engine

A composite material, wireless control technology, applied in general control systems, control/regulation systems, program control and other directions, can solve the problems of composite material manufacturers loss, operation errors, operator safety hazards, etc., to improve system reliability and safety. The effect of improving compatibility and data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

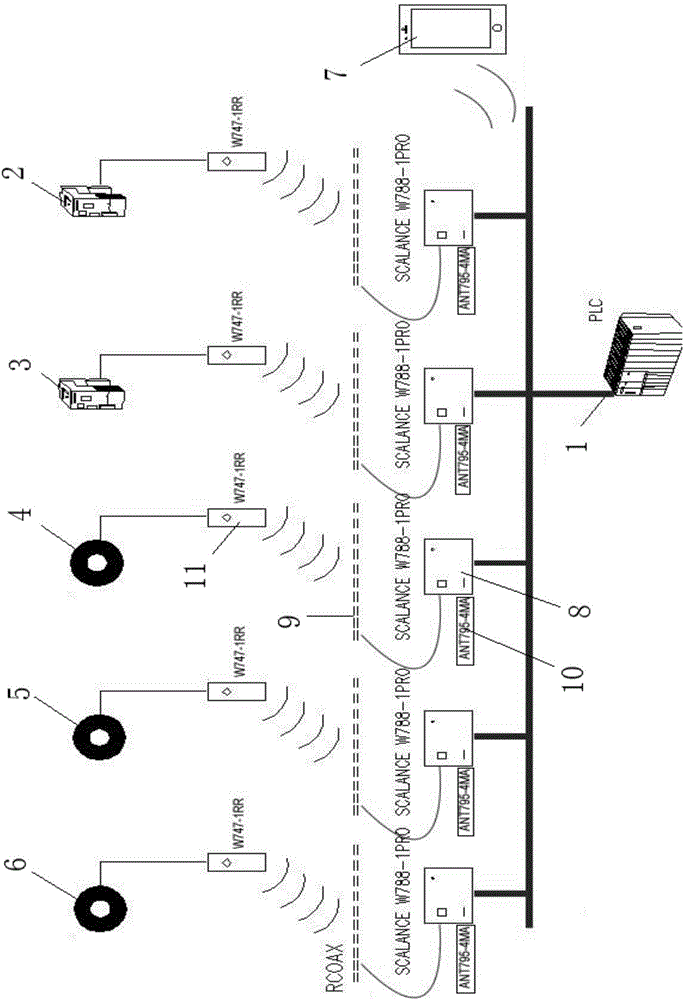

[0022] like figure 1 As shown, a composite material belt rolling host wireless control system includes a wireless Ethernet SCALANCE system based on the PROFINET industrial bus standard, a programmable logic controller (PLC) 1, a servo drive 2 with an industrial Ethernet interface, 3. Absolute encoders 4, 5, 6 of industrial Ethernet Profinet communication interface, and a mobile phone or tablet computer as the man-machine interface 7.

[0023] 1. Wireless Ethernet SCALANCE system based on PROFINET industrial bus standard: such as figure 1 , a total of 5 wireless switches (AP) 8 are used in the system, the model is SCALANCE W788-1PRO. Each AP is interconnected by PROFINET industrial bus and each corresponds to an actuator. The AP has two wireless network card interfaces, which can use 2.4 GHz and 5GHz frequency bands. Connect the RCAOX cable 9 to the first wireless network card interface. In order to avoid channel interference, five APs use five different 5GHz channels for wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com