Tire condition monitoring method and tire condition monitoring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

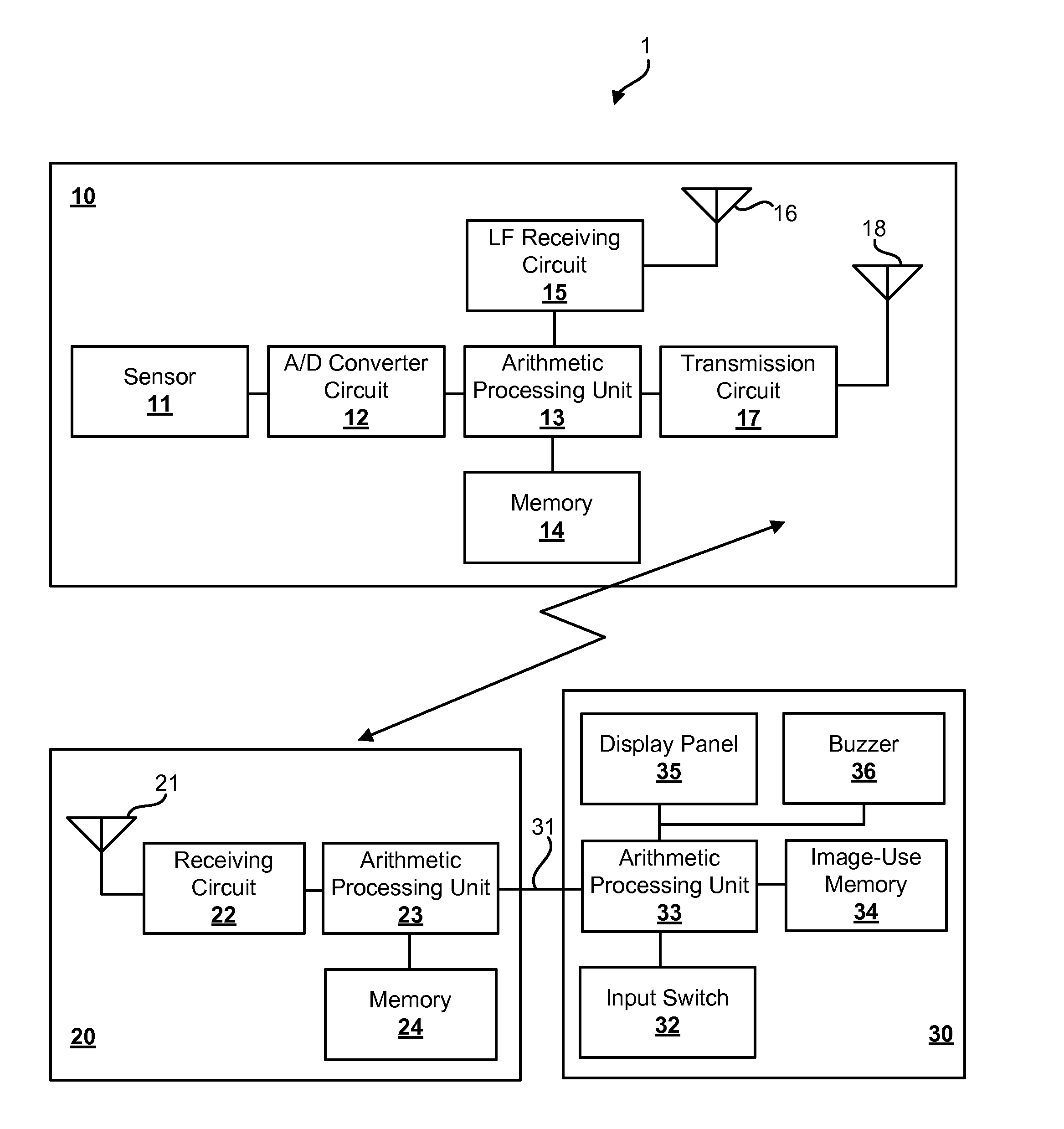

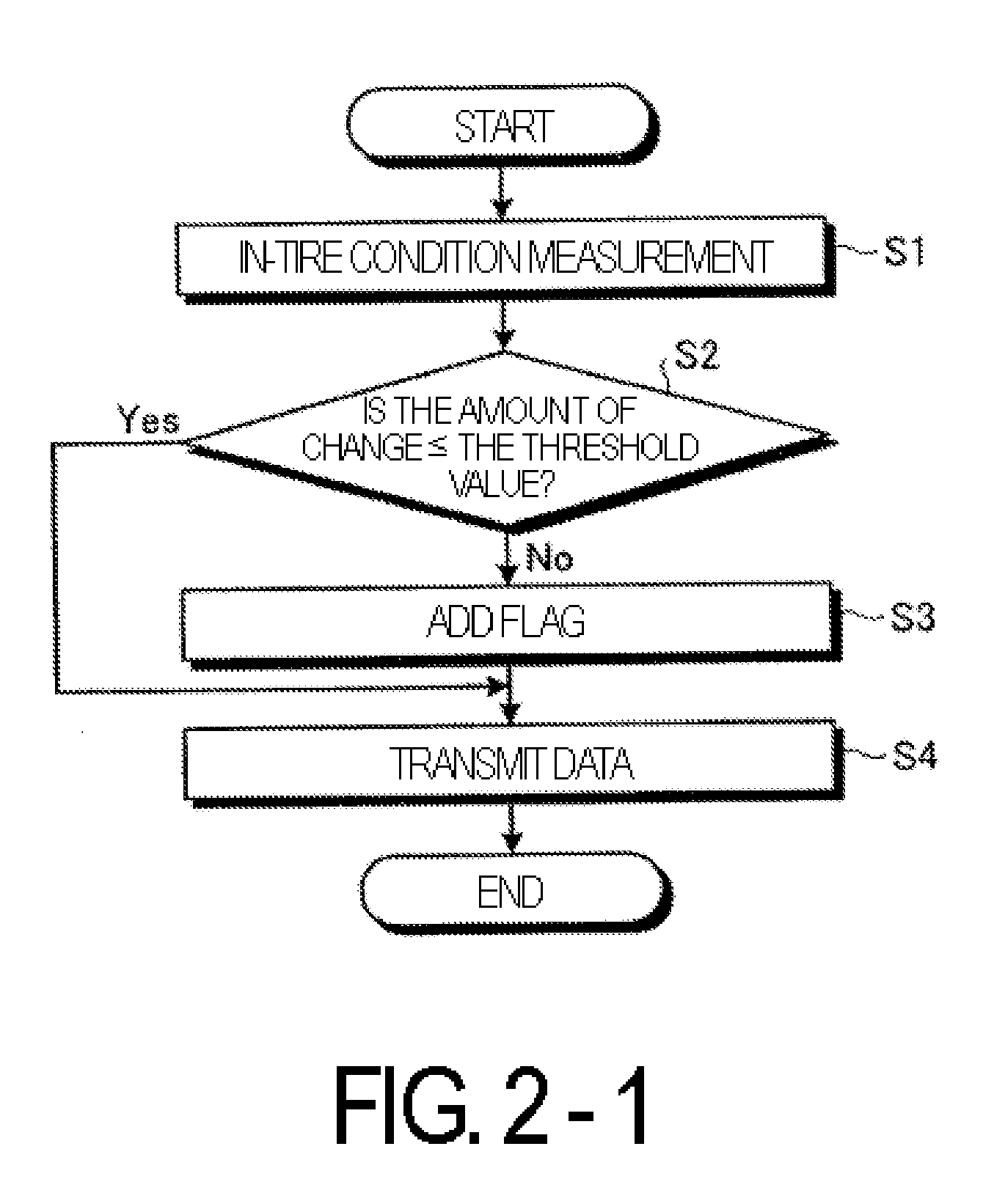

[0023]Detailed descriptions will be given below of a configuration of the technology with reference to the accompanying drawings. FIG. 1 is a component diagram illustrating a tire condition monitoring system of the technology. The configuration of the tire condition monitoring system can be applied to both the first technology and the second technology by changing the functions of the first arithmetic processing unit and the second arithmetic processing unit.

[0024]As illustrated in FIG. 1, a tire condition monitoring system 1 includes a sensor module 10, a receiver 20, and a monitoring device 30. The sensor module 10 is mounted in a tire (on a tire inside surface or on a rim peripheral surface), the receiver 20 is mounted on a vehicle body part of a vehicle, and the monitoring device 30 is mounted on a driver's seat of the vehicle.

[0025]The sensor module 10 includes a sensor 11 that detects a physical property value in the tire, an A / D converter circuit 12 that is connected to the s...

second embodiment

[0043]Next, another method for monitoring a temperature in a tire using the tire condition monitoring system 1 described above will be described using FIGS. 3-1 and 3-2. Here, FIGS. 3-1 and 3-2 are flowcharts illustrating the tire condition monitoring method of the technology. More specifically, FIG. 3-1 is a flowchart illustrating processing performed in the sensor module and FIG. 3-2 is a flowchart illustrating processing performed in the receiver and the monitoring device.

[0044]First, as illustrated in FIG. 3-1, the sensor module 10 measures the temperature as the physical property value in the tire (step S11) via the sensor 11. The sensor module 10 inputs the temperature data detected by the sensor 11 into the arithmetic processing unit 13 after converting the data from analog data to digital data via the A / D converter circuit 12. The arithmetic processing unit 13 compares the measured value from the sensor 11 with a preset threshold value and determines if the measured value is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com