Hydropower station automatic generation active output control method

A technology of automatic power generation and control methods, applied in the direction of circuit devices, AC network circuits, single-network parallel feeding arrangements, etc., can solve unresolved, vibration zone running time demonstration, unproposed time statistics, priority calculation power distribution, etc. problem, to improve the efficiency of solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

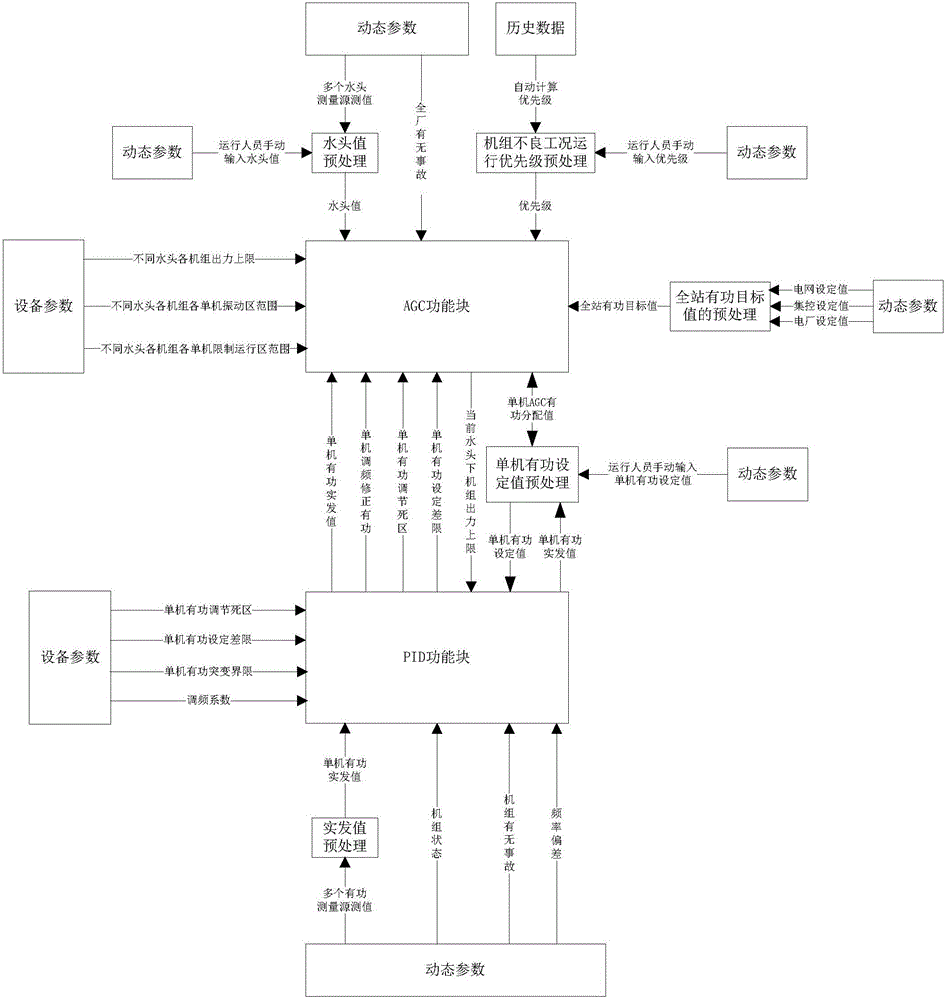

[0045] see figure 1 , figure 2 , a hydropower station automatic power generation active power output control system, including AGC function block, PID function block and preprocessing function block, equipment parameters, dynamic parameters are directly input or sent to the AGC function block, PID function block update after being processed by the preprocessing function block ;

[0046] The AGC function block and the PID function block respectively receive the preprocessing value sent by the preprocessing function block;

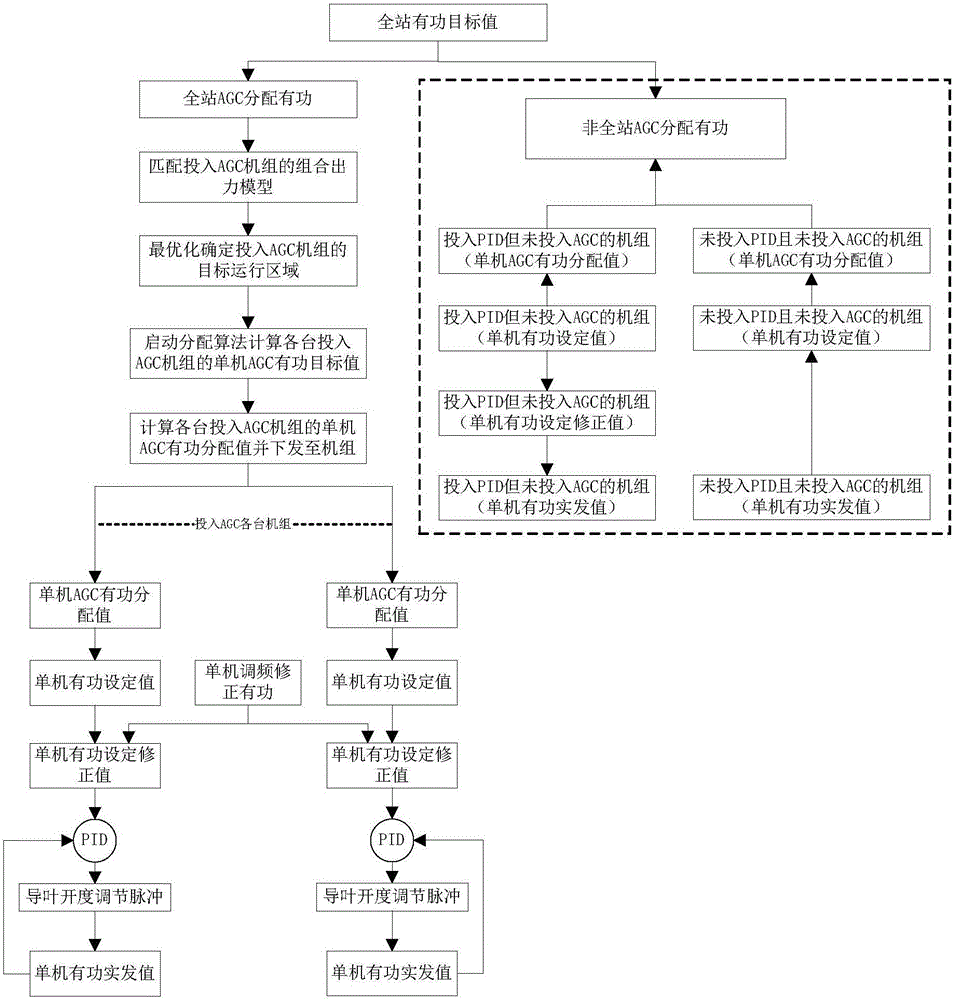

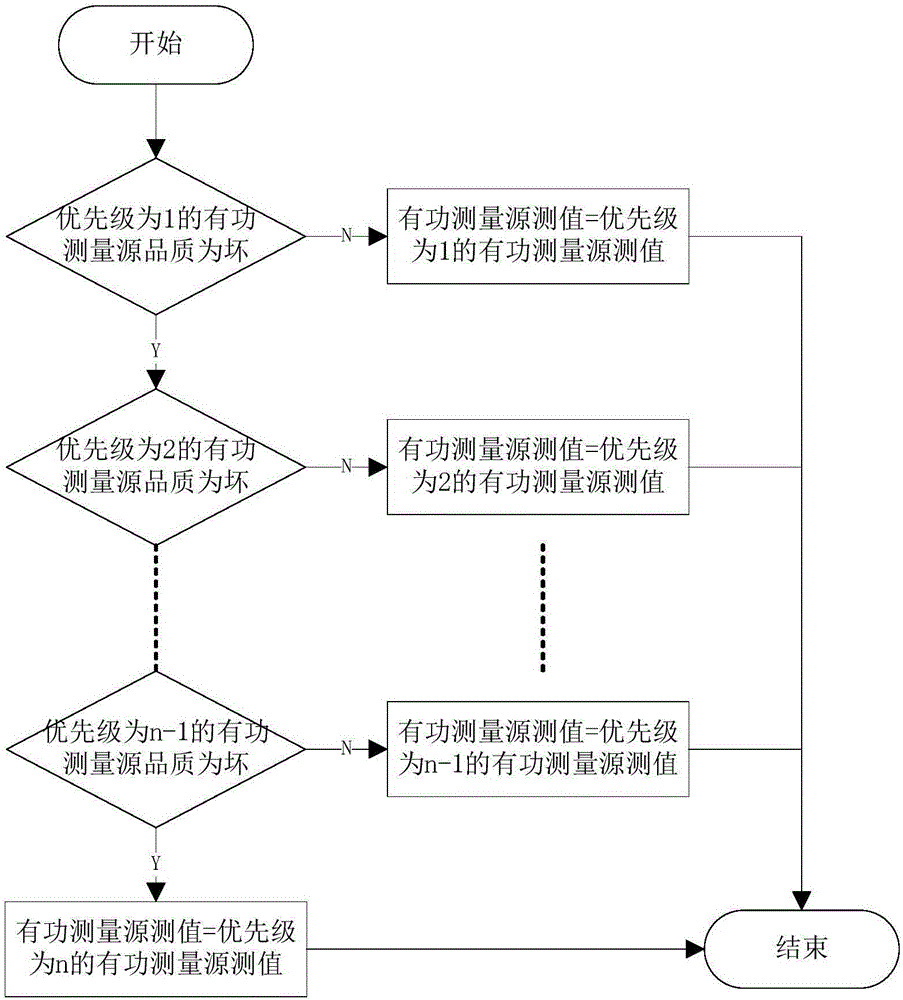

[0047] The AGC function block establishes the combined output model of the generating units of the hydropower station according to the received data, and calculates the joint operation area, joint optimal operation area and joint limited operation area according to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com