Profiled type rotating shoot clipping machine

A cutting machine and cutting machine technology, applied in agricultural machinery and implements, cutting tools, cutting equipment and other directions, can solve the problems affecting the mechanization level of main and auxiliary tip pruning in vineyards, achieve high mechanical operation efficiency, improve yield and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hydraulic station composition:

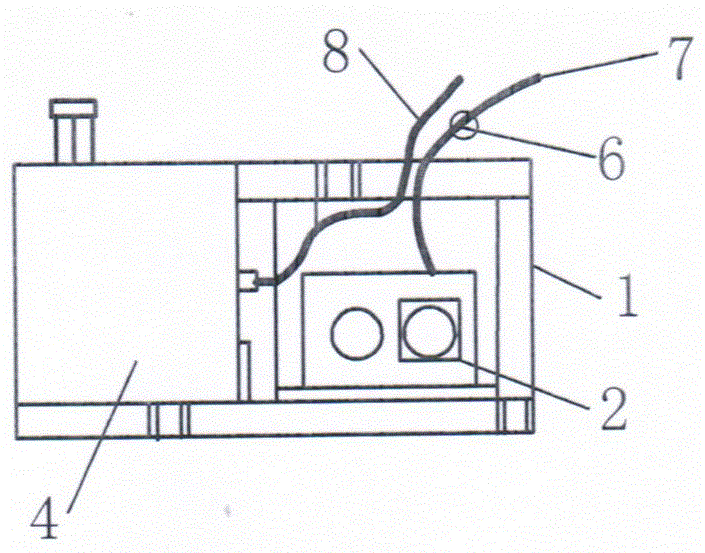

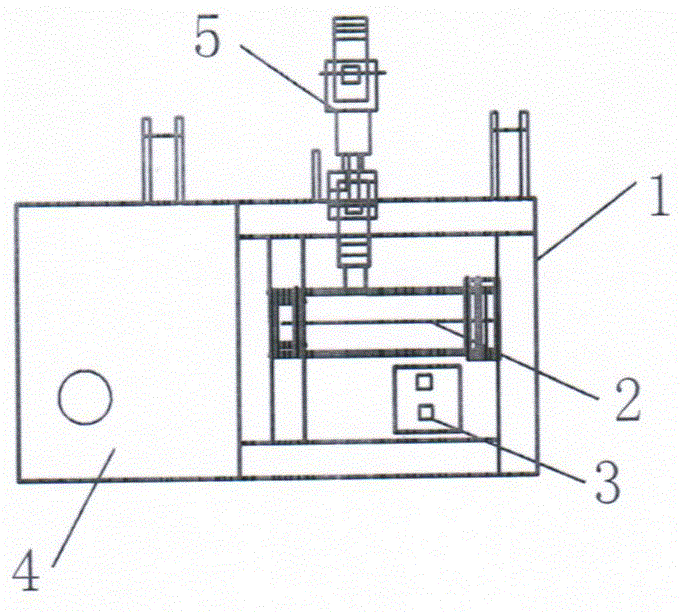

[0017] according to figure 1 and figure 2 As shown, an oil tank 4 is installed on the frame 1, an oil pump transmission box 2 is installed on one side of the oil tank, a double-connected high-pressure oil pump 3 is installed at the lower part of the oil pump transmission box, and a transmission shaft 5 is vertically connected to the upper part of the oil pump transmission box. The front oil pump oil outlet pipe 6 and the rear oil pump oil outlet pipe 7 are connected on the box, and the oil return pipe 8 is connected; the transmission shaft and the oil pump transmission box are driven to provide the blade rotation power.

[0018] Cutter Composition:

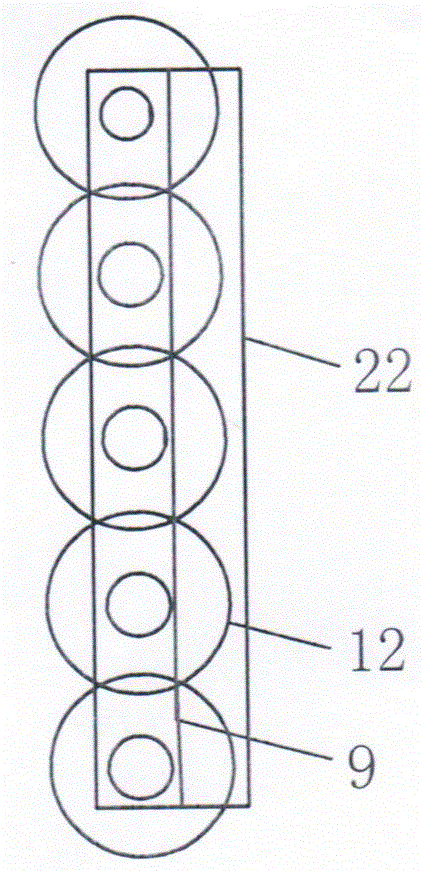

[0019] according to image 3 and Figure 4 As shown, a swing oil cylinder 20 is installed on the fixed bracket 19, and an electromagnetic reversing valve 18 is installed on the swing oil cylinder. The swing oil cylinder is connected with the telescopic oil cylinder 21 through a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com