Brier grape enzyme beverage and brewing process thereof

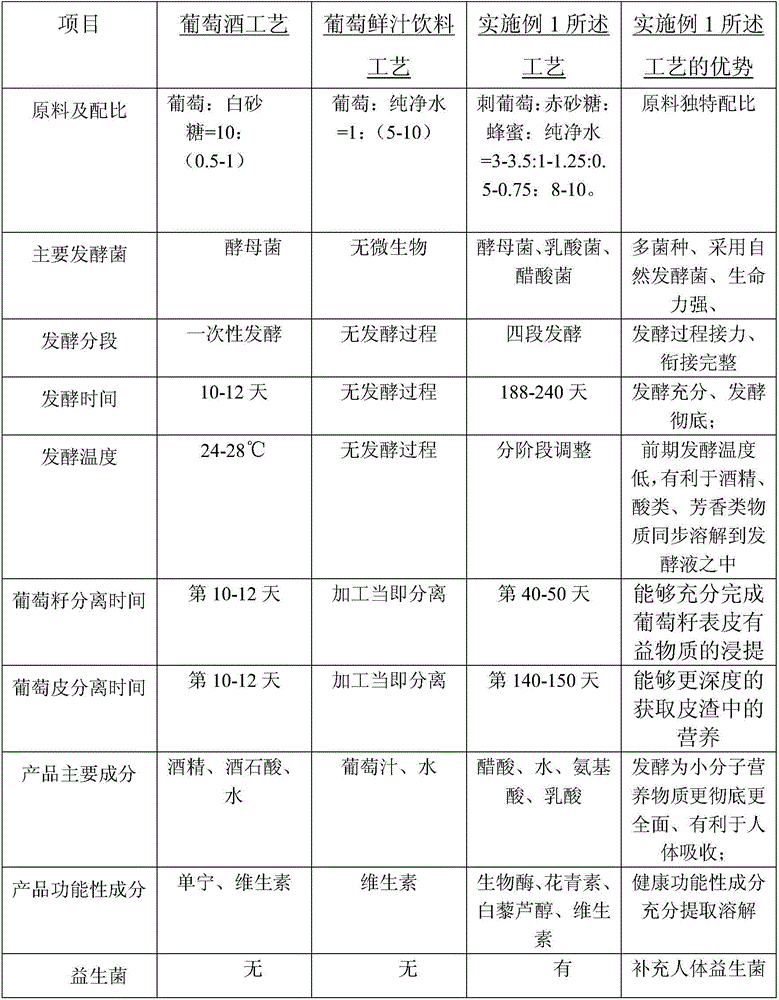

A thorn grape and process technology, which is applied in the field of thorn grape enzyme beverage and its brewing process, can solve problems such as insufficiency, and achieve the effects of easy implementation, perfect brewing results, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Raw materials (grape sorting:)

[0042] The raw materials for winemaking are thorny grapes from Hunan, China. The thorny grapes that enter the processing point must be carefully sorted again by hand. The ears are in direct contact with the land, and the equipment used to transport the grapes must be non-toxic and tasteless to ensure that the fresh fruits will not be crushed. The grapes are picked quantitatively according to the processing volume of the day, and the cut grapes must not be stored in the field or at the processing site for more than 24 hours.

[0043] 2. Destemming and crushing:

[0044] The grape berries are separated from the stems with a destemmer crusher, while the crushed pulp is immediately pumped into the fermenter. The purpose of destemming and crushing is to reduce the low-quality tannins in the fruit stems, enter the fermentation liquid, reduce the smell of the fruit stems, reduce the sense of astringency, and make the peels rupture and the j...

Embodiment 2

[0052] On the basis of embodiment 1, further comprising steps 7-12:

[0053] 7. Separation by pressing

[0054] On the 140th-150th day of fermentation (ie the end of the third stage of fermentation), the grape skins are separated from the sediment.

[0055] 8. Aging and clarification

[0056] Continue to age the fermented liquid after fermentation and separation, pay attention to the changes in temperature and specific gravity, keep the temperature below 28°C, and remove the sediment by pouring tanks (barrels) (3-4 times a year depending on the situation).

[0057] 9. Cold and stable treatment

[0058] Freeze naturally in winter or process with a freezer in other seasons. To let the fermented liquid go through the freezing of the winter stage, it is to cool the grape fermented liquid to minus 4-5°C (the critical value of the freezing point), and keep it at this temperature for a period of time (usually 7-10 days, depending on the effect), so that The turbidity sinks, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com