Full-automatic centrifugal deoiling machine

A technology of centrifugal deoiling and deoiling machine, which is applied in the direction of centrifuges, etc., can solve the problems of increased use and production costs, inability to achieve centralized deoiling, high noise, etc., to meet the needs of convenient automatic production, the deoiling effect is remarkable, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

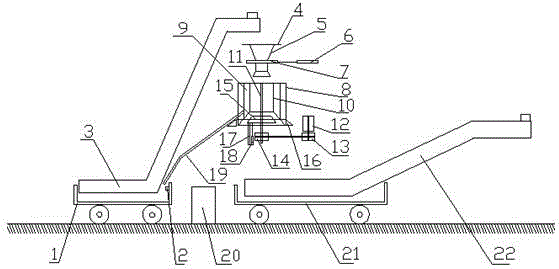

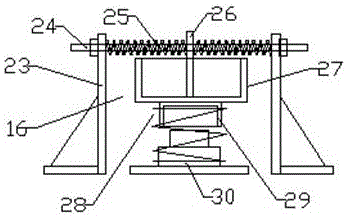

[0017] The invention provides a fully automatic centrifugal deoiler, fully automatic feeding, weighing and measuring, oil separation and discharging, the weight of the whole process of collecting oil can be set, which is convenient for production control, ultra-low noise, and can be independently concentrated Deoiling can also connect the upper and lower processes to production, and at the same time adapt to the production in different directions. It can be produced in multi-angle and multi-dimensional lines, which greatly facilitates the needs of enterprises to realize automatic production, efficient and continuous production mode; The oil in the workpiece is completely collected in the whole process, avoiding oil pollution to the environment, and improving the safety of the production process. At the same time, the oil is completely collected and recycled, saving costs, high deoiling rate, the average deoiling rate is greater than 90%, and the deoiling effect significantly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com