A support hydraulic vertical clamp

A hydraulic and vertical mounting technology, applied in the direction of clamping, supporting, manufacturing tools, etc., can solve the problems of unstable clamping force, unstable product quality, and loose positioning surface, so as to ensure consistency and transmission process Simple and convenient, ensuring stable and constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

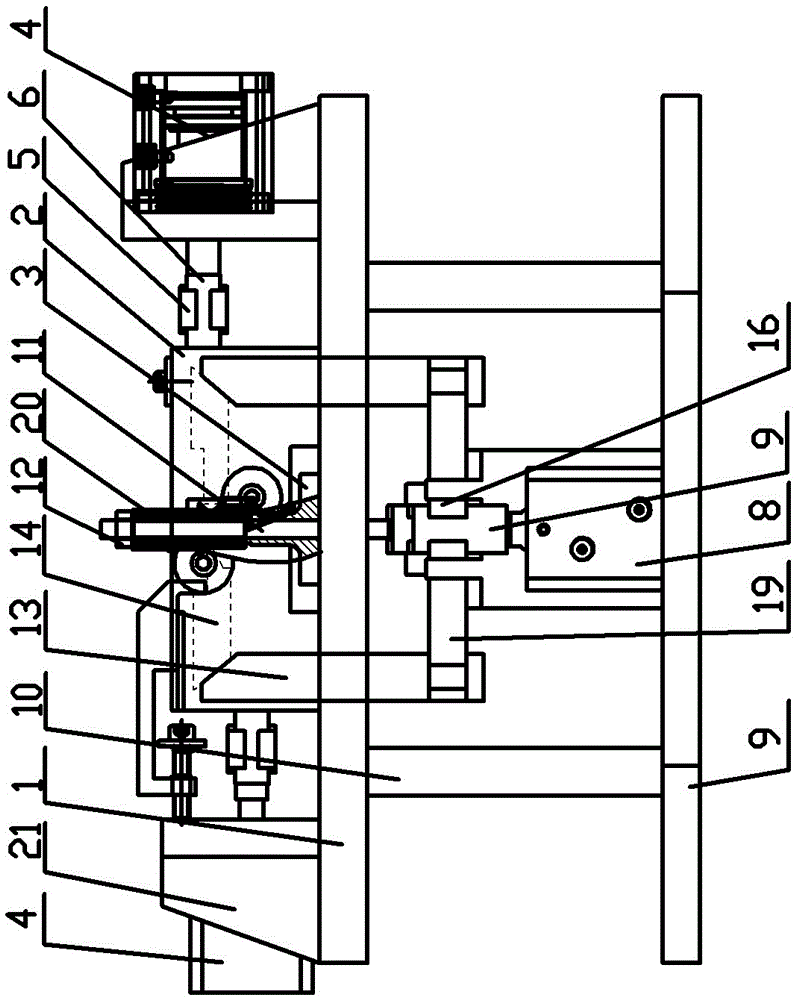

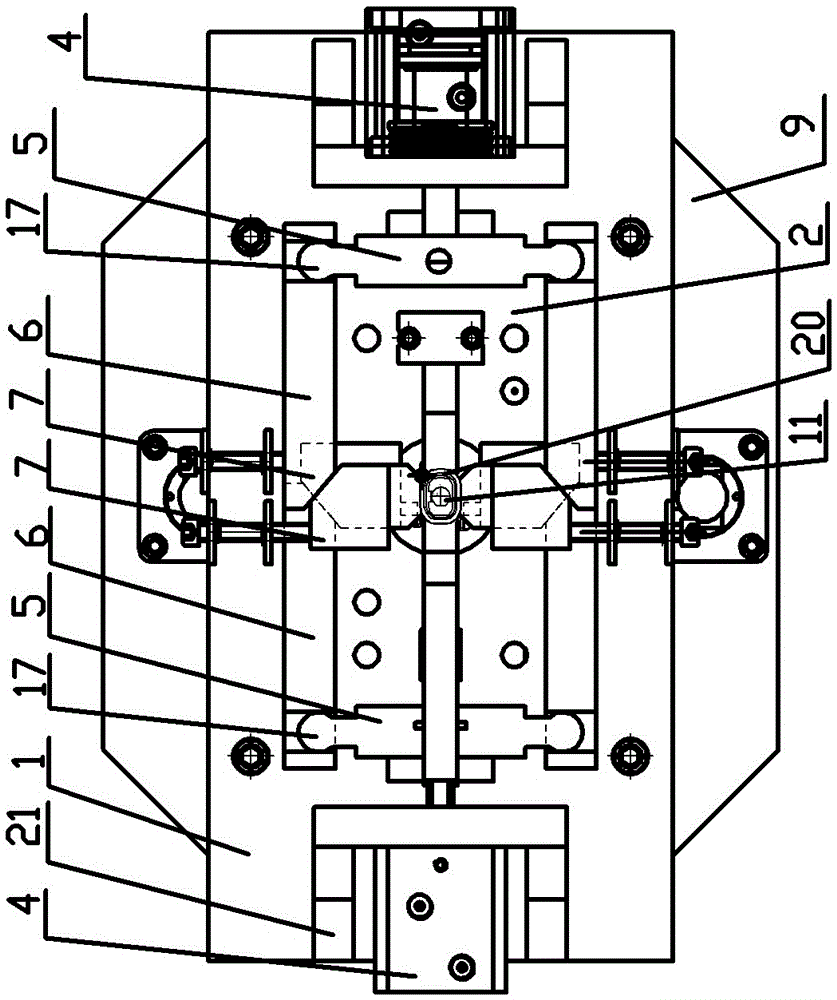

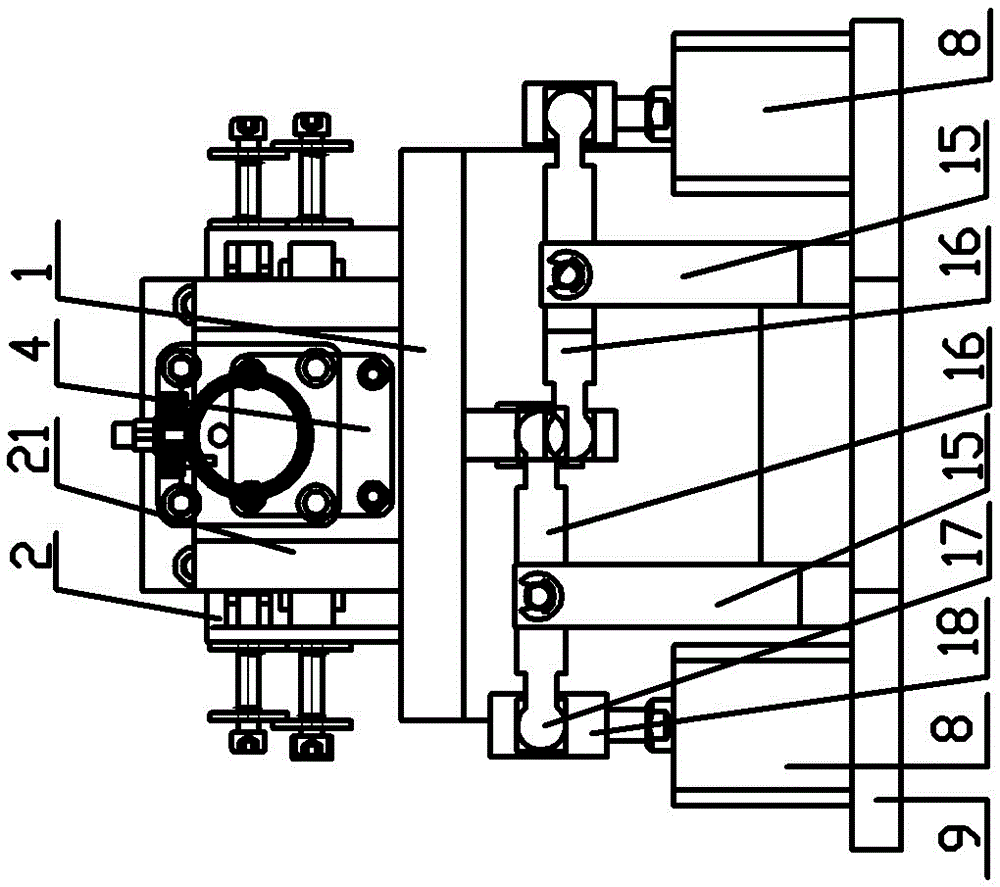

[0014] See figure 1 , figure 2 , image 3 As shown, a support hydraulic vertical clamping fixture, which includes a positioning base plate 1, a limit seat 2 is installed on the upper end of the positioning base plate 1, and a guide groove is opened in the limit seat 2, and the positioning base plate 1 is installed in the middle of the limit seat 2. There is a positioning block 3, and the left and right sides of the limit seat 2 are respectively equipped with a lateral compression cylinder 4 through a transverse seat 21, and the piston rod of the lateral compression cylinder 4 is connected to two side-by-side laterally arranged wedge mechanisms through the second hinge block 5 , the laterally arranged wedge mechanism includes a horizontal push block 6 and a lateral sliding clamping block 7 arranged in the guide groove of the limit seat 2; it is located at the lower end of the positioning base plate 1, and the front and rear ends of the limit seat 2 are respectively equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com