Efficient light grinding machine used for machining protective film and work method of efficient light grinding machine used for machining protective film

A technology of protective film and polishing machine, applied in the field of production and manufacturing, can solve problems such as affecting the image of products to customers, troublesome processing for customers, burrs on the surface, etc., and achieve the effect of improving market competitiveness, simple structure and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

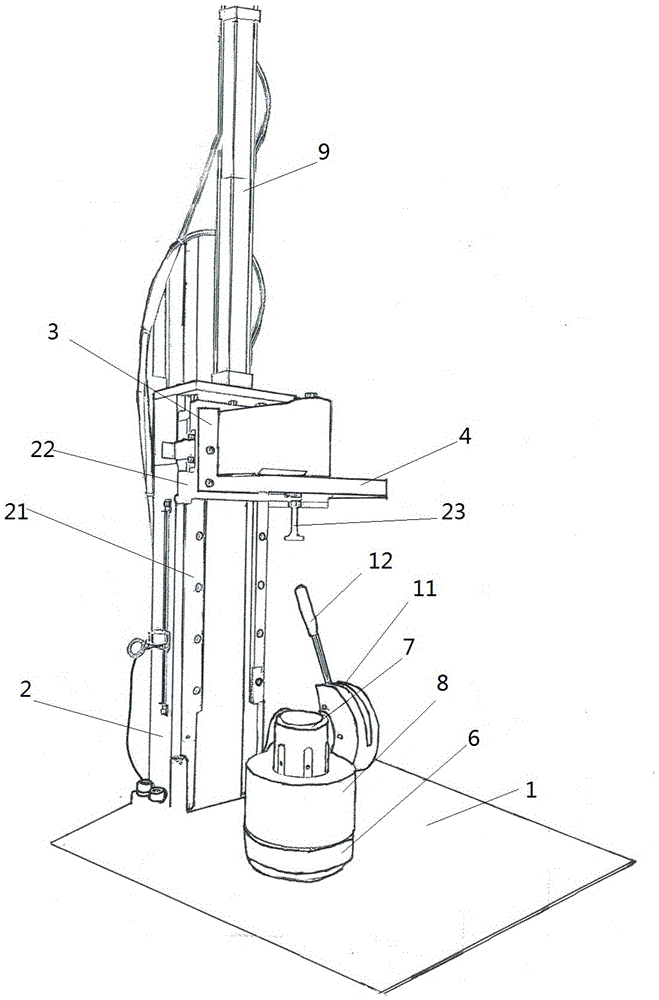

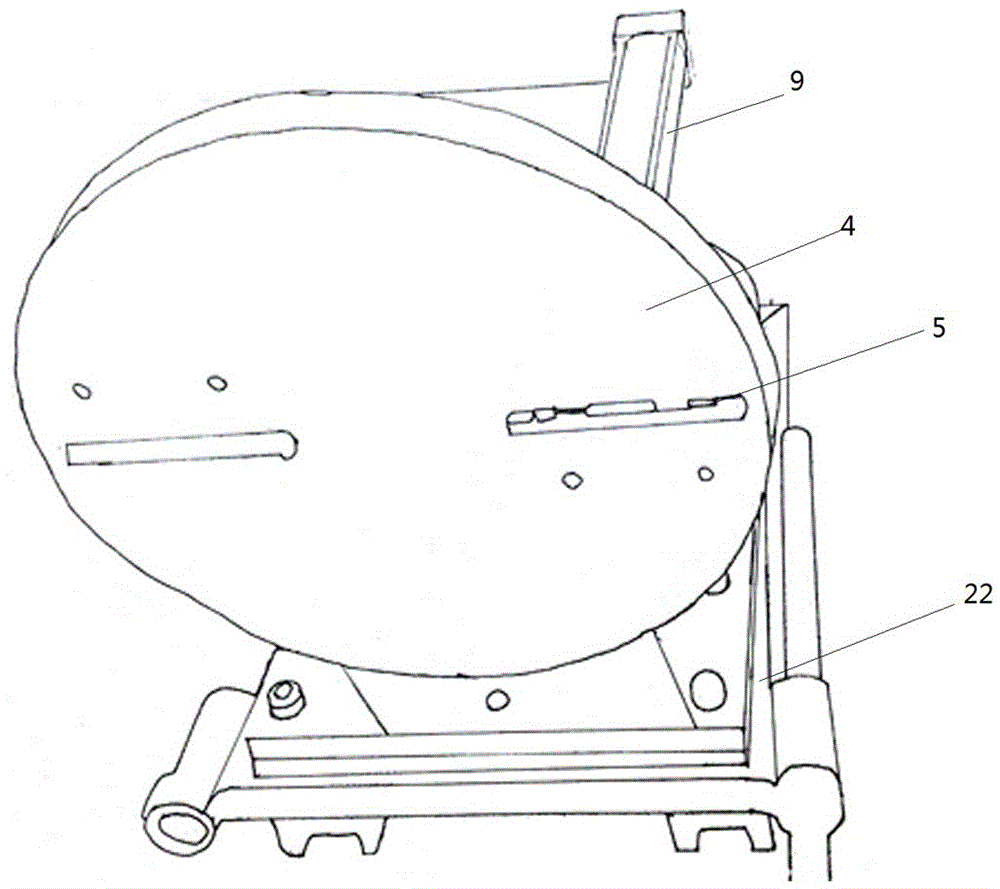

[0035] Such as figure 1 and figure 2 A high-efficiency polishing machine for protective film processing is shown, including: a workbench 1, a column 2, a driving mechanism, an executive mechanism and a control mechanism, and an oil cylinder 9 is arranged in the driving mechanism;

[0036] The relationship between the above components is as follows:

[0037] The column 2 is arranged on one side of the workbench 1, the top of the column 2 is provided with a fixing part 3, the fixing part 3 is provided with a cutterhead 4, and the bottom of the cutterhead 4 is provided with Knife sharpening 5, the workbench 1 is provided with a positioning disc 6, the middle of the positioning disc 6 is provided with a positioning column 7, and the positioning disc 6 is provided with a stopper 8 for adjusting the width of the protective film , and, the positioning disc 6 is matched with the cutter head 4; the driving mechanism is connected with the actuator, the oil cylinder 9 is connected wit...

Embodiment 2

[0045] The light grinder described in this embodiment has the same structure as that in Embodiment 1.

[0046] Such as figure 1 and figure 2 A high-efficiency polishing machine for protective film processing is shown, including: a workbench 1, a column 2, a driving mechanism, an executive mechanism and a control mechanism, and an oil cylinder 9 is arranged in the driving mechanism;

[0047] The relationship between the above components is as follows:

[0048] The column 2 is arranged on one side of the workbench 1, the top of the column 2 is provided with a fixing part 3, the fixing part 3 is provided with a cutterhead 4, and the bottom of the cutterhead 4 is provided with Knife sharpening 5, the workbench 1 is provided with a positioning disc 6, the middle of the positioning disc 6 is provided with a positioning column 7, and the positioning disc 6 is provided with a stopper 8 for adjusting the width of the protective film , and, the positioning disc 6 is matched with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com