High-modulus rubber asphalt concrete

A rubber asphalt, high modulus technology, applied in the field of rubber asphalt concrete, can solve the problems of easy deformation, rutting, high temperature difference, etc., achieve high resistance, prolong service life, and improve the effect of rutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the protection scope of the present invention middle.

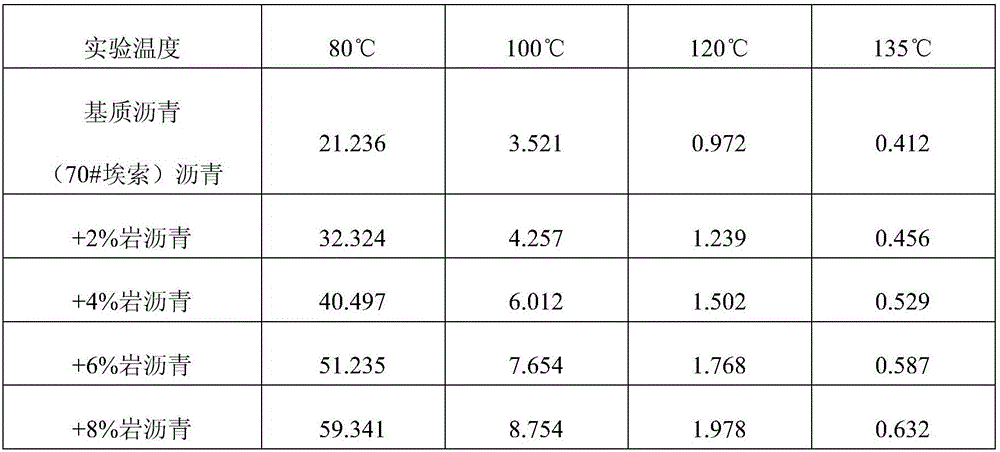

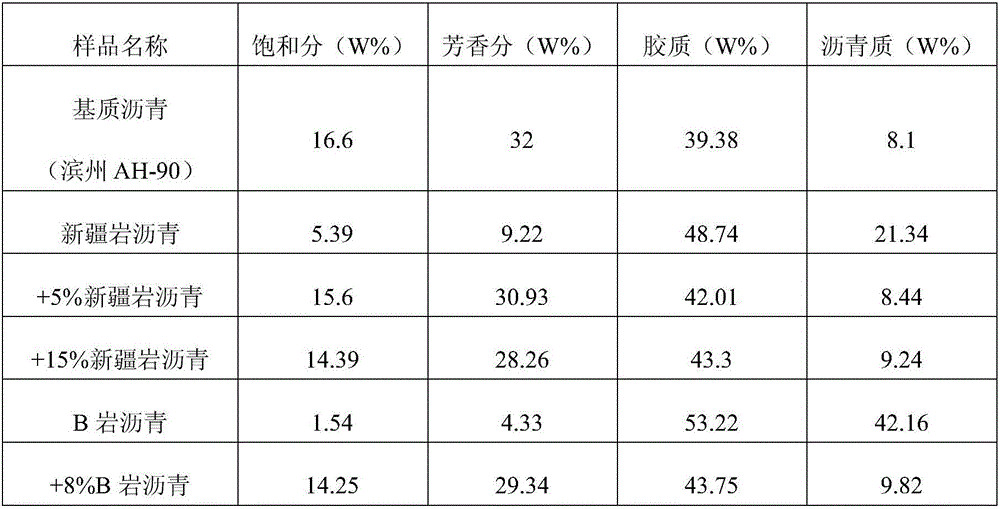

[0016] The invention provides a kind of high modulus rubber asphalt concrete, adding rock asphalt accounting for 2 to 15% of the mass of matrix asphalt to become high modulus asphalt; adding rubber powder to high modulus asphalt to produce high modulus rubber asphalt , the amount of rubber powder added is the same as the amount of rubber powder added to the base asphalt; various types of stones are added to the high modulus rubber asphalt to produce high modulus rubber asphalt concrete, and various types of stones can be added according to the proportion of ordinary asphalt concrete . That is: in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com