Lightweight Paper Honeycomb Composite Panel with High Adhesive Hot Melt Adhesive Film

A hot-melt adhesive film, high-adhesive technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve the problems of increasing structural weight, etc., to achieve high peel strength and heat insulation performance High, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

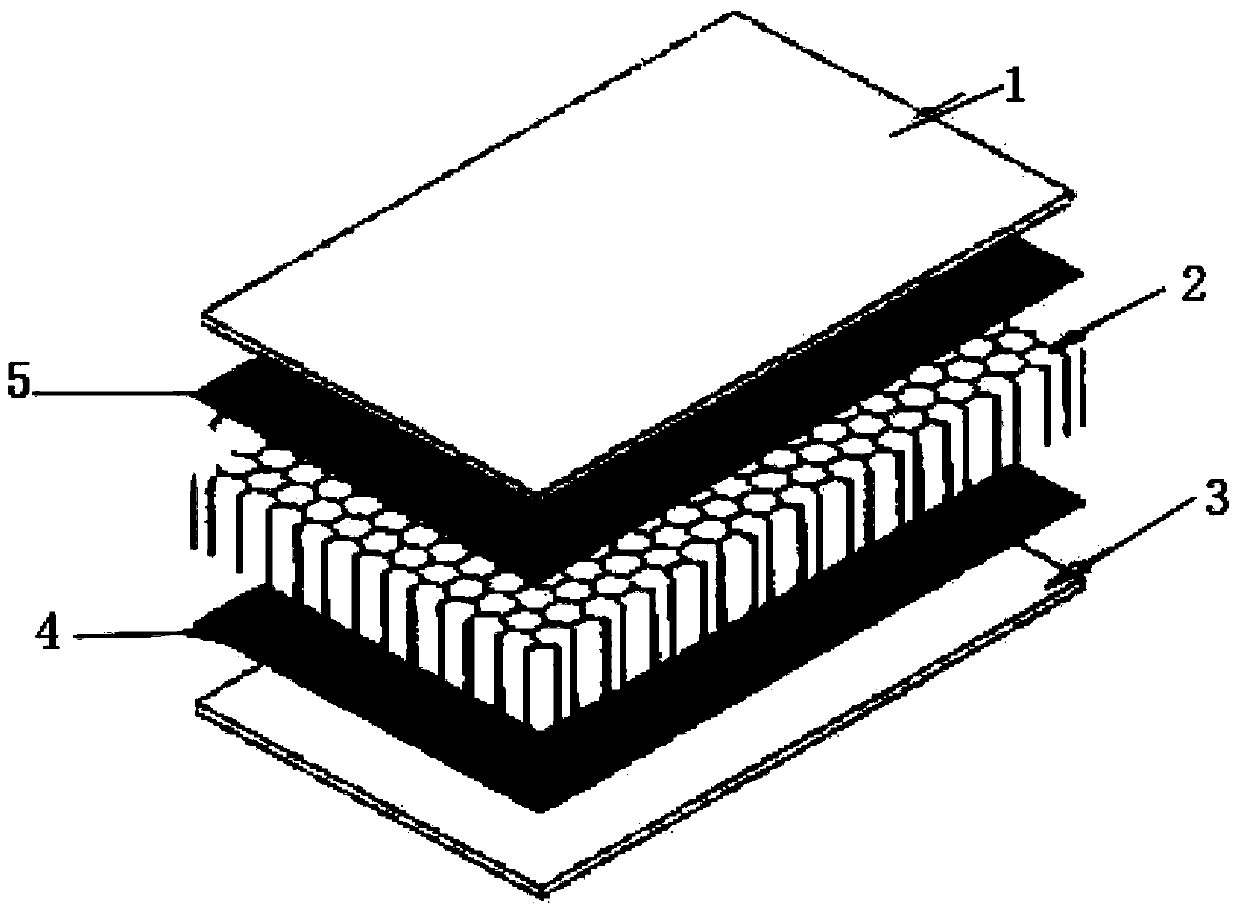

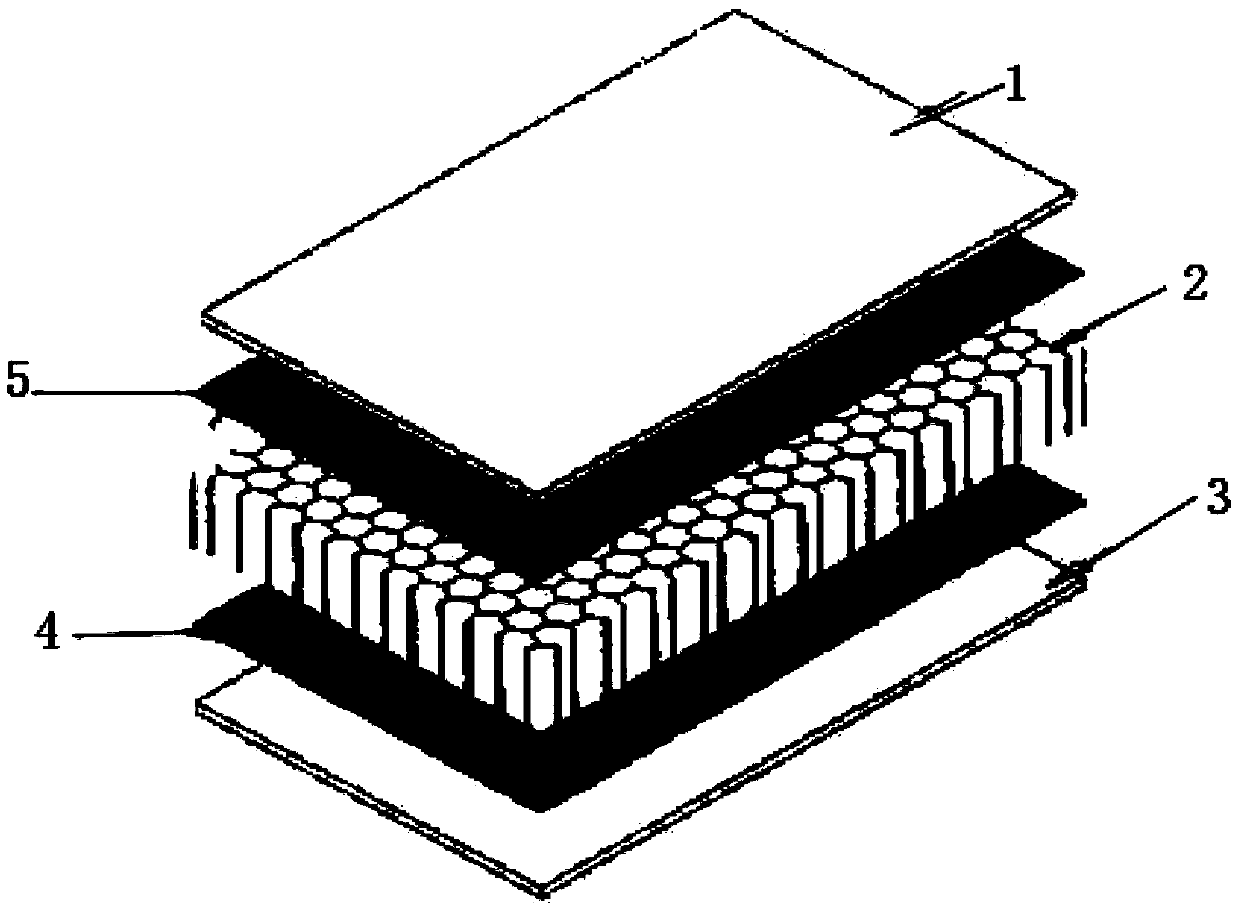

[0029] The lightweight paper honeycomb composite board with high-adhesion hot-melt adhesive film in this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, a honeycomb core stacked sequentially from bottom to top Material 2, the upper hot-melt adhesive film 5 and the upper skin 1 are composited, and the upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. Including by weight: 10 parts of diphenylmethane bismaleimide, 3 parts of o-diallyl bisphenol A, 5 parts of diallyl bisphenol A, 5 parts of polyether sulfone, 6 parts of polyether ketone ketone, 10 parts of imide, 1 part of emulsifier, 3 parts of acetone, 3 parts of ethylene glycol monomethyl ether; the raw materials of the lower hot-melt adhesive film 4 and the upper hot-melt adhesive film 5 include the following components by weight: 40 parts epoxy resin, 10 parts boric acid, 8 parts dimethyl polysiloxane, 10 parts low...

Embodiment 2

[0038]The lightweight paper honeycomb composite board with high-adhesion hot-melt adhesive film in this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, a honeycomb core stacked sequentially from bottom to top Material 2, the upper hot-melt adhesive film 5 and the upper skin 1 are composited, and the upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. Including by weight: 20 parts of diphenylmethane bismaleimide, 8 parts of o-diallyl bisphenol A, 15 parts of diallyl bisphenol A, 10 parts of polyether sulfone, 12 parts of polyether ketone ketone, 20 parts of imide, 5 parts of emulsifier, 6 parts of acetone, 8 parts of ethylene glycol monomethyl ether (to improve stability); the raw materials of the lower hot-melt adhesive film 4 and the upper hot-melt adhesive film 5 include by weight The following components: 50 parts epoxy resin, 20 parts boric acid, 15 parts dimethyl...

Embodiment 3

[0047] The lightweight paper honeycomb composite board with high-adhesion hot-melt adhesive film in this embodiment, the composite board includes a lower skin 3, a lower hot-melt adhesive film 4, a honeycomb core stacked sequentially from bottom to top Material 2, the upper hot-melt adhesive film 5 and the upper skin 1 are composited, and the upper skin 1 and the lower skin 3 are glass cloth prepregs formed by impregnating glass cloth with a resin composition. Including by weight: 10 parts of diphenylmethane bismaleimide phenol, 8 parts of o-diallyl bisphenol A, 5 parts of diallyl bisphenol A, 10 parts of polyether sulfone, 6 parts of polyether ketone ketone, 20 parts of imide, 1 part of emulsifier, 6 parts of acetone, 3 parts of ethylene glycol monomethyl ether; the raw materials of the lower hot-melt adhesive film 4 and the upper hot-melt adhesive film 5 include the following components by weight: 40 parts epoxy resin, 20 parts boric acid, 8 parts dimethyl polysiloxane, 20 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com